Sandwich Panel Production Line

Sandwich Panel Production Line

Thesandwich panel production line uses advanced techniques, integratinggas, electricity and machinery; this line is special equipment for processingcolored steel sandwich panel. The speed of our sandwich panelproduction line can be adjusted by frequency converter, and it can process onesandwich panel at a time. The sandwichpanel production line consists of a decoiler, molding core, and compound part,which can finish knocking the groove, implant glue, heating, compound,rolling, grooving, finishing, and air-powered, automatic cutting. This equipment is essential for producingfactories, roof tiles and wall panels for warehouses.

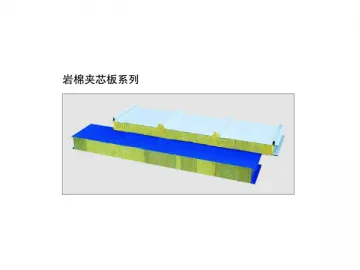

TheHDF series sandwich panel production line producessandwich panels with new building material which are beautiful in appearance,lightweight and feature stability and solidity. The use of sandwich panels for building various large scale projectslike supermarkets, workshops, and warehouses makes the work fast andconvenient. They can also be used toconstruct refrigerator panels, clearing rooms, etc.

TheHDF series sandwich panel production line was developed by our company throughseveral years of experience. From simplefunction HDF-2 to multifunction HDF-8, we can apply variousoptions or adapt special panel product-functions to suit the needs of ourcustomers.

TheHDF series sandwich panel production line can produce H Plates, Tongue andGroove Panel Plates with Expandable Polystyrene (EPS) or Rock Wool, as well asCap Joint Panels, Screw Panels, Seam Panel Corrugations and joint-hidden panelplates combined with HDY-2 roll forming machine.

Features

1. Using PLC combined with a touch screen,our sandwich panel production line is very convenient and reliable to use andcan automatically fix length to cut and count.

2. This line can produce various wallpanels, i.e., tongue, groove, and various joint refrigerator panels.

3. The production line can be used to produceEPS or rock wool and glass wool panel.

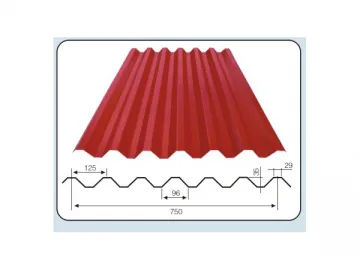

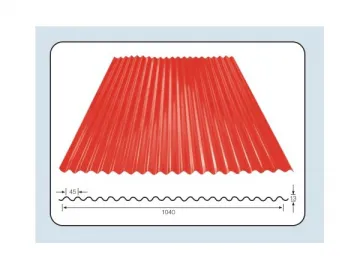

4. Corrugated panel and joint-hidden panelplate with various options can be produced by our sandwichpanel production line.

5. We can design our sandwich panelproduction line with special function to meet any special requirements ourcustomers.

Technical Parameters

Dimension(mm): 36000×2400×2700

Weight(ton): 16

TotalPower (kw): 32

ProductionRate (m/min): 0-4.5

PlateMaterial: Color steel or stainless plate

MaterialThickness (mm): 0.3-0.6

CoreMaterial: EPS, rock wool, polyurethane

CoreThickness (mm): 48-298

As a China sandwichpanel production line manufacturer, Haide Machinery Manufacturing Companyprovides a comprehensive range of roll forming machines, including sandwichpanel production lines, tile forming machines, corrugated sheet formingmachines, and more. Our company hasreceived the ISO9001 certificate and our products have been CE certified. We are located in Botou City; about 200 kilometers away from Beijing, the capital of China. Our location provides us with easy access toconvenient sea, land and air transportation, resulting in reduced shipping feesfor our customers.

For more detailed information, please continue browsing our website or contactus directly. We look forward to workingwith you.

Links:https://globefindpro.com/products/110556.html

-

Roof Panel Forming Machine

Roof Panel Forming Machine

-

Laser Cutting Machine, 700-1500W

Laser Cutting Machine, 700-1500W

-

T10 LED Fluorescent Tube, YK-B1011J

T10 LED Fluorescent Tube, YK-B1011J

-

Tile Forming Machine

Tile Forming Machine

-

Welded

Wire Mesh Panel

Welded

Wire Mesh Panel

-

Barbed Wire

Barbed Wire

-

Die Board Laser Cutting Machine, 200-300W

Die Board Laser Cutting Machine, 200-300W

-

T10 LED Fluorescent Tube, YK-B1020J

T10 LED Fluorescent Tube, YK-B1020J

-

Wall Panel Forming Machine

Wall Panel Forming Machine

-

Corrugated Sheet Forming Machine

Corrugated Sheet Forming Machine

-

T5 LED Fluorescent Tube, YK-B1091, YK-B1092, YK-B1093, YK-B1094

T5 LED Fluorescent Tube, YK-B1091, YK-B1092, YK-B1093, YK-B1094

-

Abrasive Cutting Machine

Abrasive Cutting Machine