Wall Panel Forming Machine

Wall PanelForming Machine

Features

The wall panel forming machine features highspeed, high production, good performance, low labor and is economical. It is the best choice for producing the metalsheet cold roll forming products.

Application

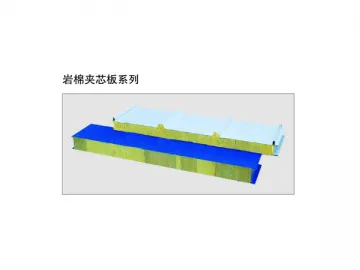

Our roll forming machine produces different kinds of wall panels. The panels are primarily used in temporarybuilding sites, steel structure workshops, and other public buildings andfeature fast construction speed. Ourwall panels are durable, have an attractive appearance, etc.

Machine Components

| Guiding Table | 1 set |

| Manual Decoiler | 1 set |

| Main Forming Machine | 1 set |

| PLC Control System | 1 set |

| Hydraulic Cutting Station | 1 set |

| Output Table | 1 set |

Technical Specifications

| Item | Description |

| Material Width | 914mm-1250mm |

| Material Thickness | 0.3mm-0.6mm |

| Material | PPGI HDGI |

| Yield Stress | 235Mpa |

| Material of Roller | 45# steel plant hard chromium 0.05mm |

| Diameter of Shaft | 70mm |

| Voltage | AC380v/50hz or per customer’s requirement |

| Motor Power | 5.5kw |

| Hydraulic Power | 4kw |

| Stand | 11-18 |

| Control System | Mitsubishi PLC frequency conversion |

| Hydraulic Cutting Material | Cr12 heat treatment |

| Speed | 8-15m/min |

| Decoiler | 5 tons manual or hydraulic |

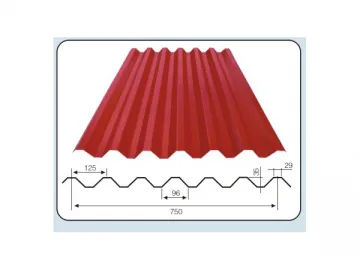

Yx15-225-900

| Item | Description |

| Material Width | 1000mm |

| Material Thickness | 0.3mm-0.8mm |

| Material | PPGI HDGI |

| Yield Stress | 235Mpa |

| Material of Roller | 45# steel plated hard chromium 0.05mm |

| Diameter of Shaft | 70mm |

| Voltage | AC380v/50hz or per customer’s requirement |

| Motor Power | 4kw |

| Hydraulic Power | 3kw |

| Stand | 13 |

| Control System | Mitsubishi PLC frequency conversion |

| Hydraulic Cutting Material | Cr12 heat treatment |

| Speed | 8-15m/min |

| Decoiler | 5 tons manual or hydraulic |

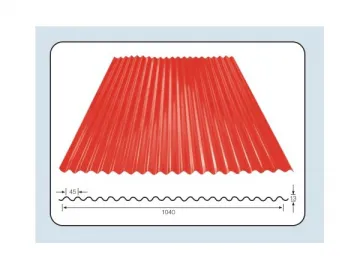

C10

| Item | Description |

| Material Width | 1250mm |

| Material Thickness | 0.3mm-0.8mm |

| Material | PPGI HDGI |

| Yield Stress | 235Mpa |

| Material of Roller | 45# steel plated hard chromium 0.05mm |

| Diameter of Shaft | 70mm |

| Voltage | AC380v/50hz or per customer’s requirement |

| Motor Power | 4kw |

| Hydraulic Power | 3kw |

| Precision | 10m±2mm |

| Control System | Mitsubishi PLC frequency conversion |

| Hydraulic Cutting Material | Cr12 heat treatment |

| Speed | 8-15m/min |

| Decoiler | 5 tons manual or hydraulic |

Flow Chart

Decoiling the sheet---Guiding the sheet---Roll forming---Measuring thelength---Cutting the sheet---on the output table

Machine Placement and Operator

The wall panel forming machine should be placed on an even cement floorand lifted with a lifting device with a lifting capacity not less than fivetons. The machine requires space forstoring materials and laying the machine and enough room for it tooperate. The forming machine requiresone operator and one porter.

Founded in 1996, we are a China-based wall panel forming machinemanufacturer and supplier. Through ouryears of experience and continued efforts of our dedicated staff, we offercustomers a great variety of roll forming machines, like double layer formingmachines, tile forming machines, wall panel forming machines, sandwich panelproduction lines, and others. Ourlocation in Botou City gives us easy accessto convenient air, land and sea transportation. This keeps our costs down, and reduces transportation costs for ourcustomers.

If you have a need for any of our products, please feel free to contact us atHaide Machinery Manufacturing Company. We look forward to working with you.

Links:https://globefindpro.com/products/110552.html

-

T10 LED Fluorescent Tube, YK-B1020J

T10 LED Fluorescent Tube, YK-B1020J

-

Die Board Laser Cutting Machine, 200-300W

Die Board Laser Cutting Machine, 200-300W

-

Sandwich Panel Production Line

Sandwich Panel Production Line

-

Roof Panel Forming Machine

Roof Panel Forming Machine

-

Laser Cutting Machine, 700-1500W

Laser Cutting Machine, 700-1500W

-

T10 LED Fluorescent Tube, YK-B1011J

T10 LED Fluorescent Tube, YK-B1011J

-

Corrugated Sheet Forming Machine

Corrugated Sheet Forming Machine

-

T5 LED Fluorescent Tube, YK-B1091, YK-B1092, YK-B1093, YK-B1094

T5 LED Fluorescent Tube, YK-B1091, YK-B1092, YK-B1093, YK-B1094

-

Abrasive Cutting Machine

Abrasive Cutting Machine

-

T10 LED Fluorescent Tube, YK-B1034

T10 LED Fluorescent Tube, YK-B1034

-

T10 LED Fluorescent Tube, YK-B1031J, YK-B1032J, YK-B1033J

T10 LED Fluorescent Tube, YK-B1031J, YK-B1032J, YK-B1033J

-

Impact Machine

Impact Machine