Roof Panel Forming Machine

Roof Panel Forming Machine

Features

This type of roof panel forming machine features high speed, high production, good performance, low labor and is economical. It is the best choice for producing metal sheet cold roll form products.

Application

Our roof panel forming machine produces different kinds of steel panel tiles for roofs and walls. The tiles are primarily used for temporary building sites, steel structure workshops, and other public buildings and feature fast construction speed. Our tiles are durable, have an attractive appearance, etc.

Technical parameters

| Item | Description |

| Material Width | 914mm-1250mm |

| Material Thickness | 0.5mm-1mm |

| Material | PPGI HDGI |

| Yield Stress | 235-330Mpa |

| Material of Roller | 45# steel plant hard chromium 0.05mm |

| Diameter of Shaft | 70-80mm |

| Voltage | AC380v/50hz or per customer’s requirement |

| Motor Power | 5.5-7.5kw |

| Hydraulic Power | 4kw |

| Stand | 11-22 |

| Control System | Mitsubishi PLC frequency conversion |

| Hydraulic Cutting Material | Cr12 heat treatment |

| Speed | 8-15m/min |

| Decoiler | 5 tons manual or hydraulic |

Main Equipment

Our roof panel forming machine consists of a manual decoiler, feeding platform, main molding core, shearing machine, hydraulic station, computer control cabinet, high precision counter, and driven system protective covering panel supporting table.

Flow chart

Decoiling the sheet---Guiding the sheet---Leveling the sheet---Roll forming---Punching the sheet---Measuring the length---Cutting the sheet---on the output table

Machine Placement and Operator

The roof panel forming machine should be placed on an even cement floor and lifted with a lifting device with a lifting capacity not less than five tons. The machine requires space for storing materials, laying the machine and enough room for it to operate. The forming machine requires one operator and one porter. The temperature in the workspace should be no less than -14℃.

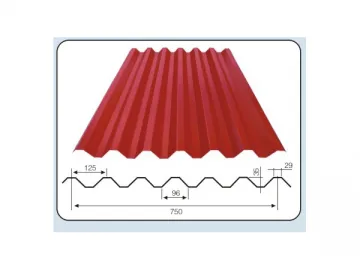

Technical Specifications YX35-125-750

| Item | Description |

| Material Width | 1000mm |

| Material Thickness | 0.5mm-1mm |

| Material | PPGI HDGI |

| Yield Stress | 235Mpa |

| Material of Roller | 45# steel plated hard chromium 0.05mm |

| Diameter of Shaft | 70mm |

| Voltage | AC380v/50hz or per customer’s requirement |

| Motor Power | 7.5kw |

| Hydraulic Power | 4kw |

| Stand | 18 |

| Control System | Mitsubishi PLC frequency conversion |

| Hydraulic Cutting Material | Cr12 heat treatment |

| Speed | 8-15m/min |

| Decoiler | 5 tons manual or hydraulic |

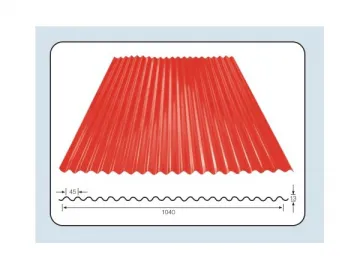

Technical Specifications YX35-200-1000

| Item | Description |

| Material Width | 1250mm |

| Material Thickness | 0.5mm-1mm |

| Material | PPGI HDGI |

| Yield Stress | 235Mpa |

| Material of Roller | 45# steel plated hard chromium 0.05mm |

| Diameter of Shaft | 70mm |

| Voltage | AC380v/50hz or per customer’s requirement |

| Motor Power | 5.5kw |

| Hydraulic Power | 4kw |

| Stand | 18 |

| Control System | Mitsubishi PLC frequency conversion |

| Hydraulic Cutting Material | Cr12 heat treatment |

| Speed | 8-15m/min |

| Decoiler | 5 tons manual or hydraulic |

As an experienced roof panel forming machine manufacturer based in China, Haide Machinery Manufacturing Company produces an extensive line of forming equipment, such as Curved Roofing Sheet roll forming machines, roll forming machines, metal sheet forming machines, and so on. We can manufacture our forming machine according to customers' specific requirements. As a result of our high quality products and dependable service, we have been awarded the ISO9001 certificate.

Thank you for visiting our website. Please feel free to contact us for more information. We look forward to hearing from you.

Links:https://globefindpro.com/products/110557.html

-

Laser Cutting Machine, 700-1500W

Laser Cutting Machine, 700-1500W

-

T10 LED Fluorescent Tube, YK-B1011J

T10 LED Fluorescent Tube, YK-B1011J

-

Tile Forming Machine

Tile Forming Machine

-

Welded

Wire Mesh Panel

Welded

Wire Mesh Panel

-

Barbed Wire

Barbed Wire

-

MPO Ribbon Patch Cable

MPO Ribbon Patch Cable

-

Sandwich Panel Production Line

Sandwich Panel Production Line

-

Die Board Laser Cutting Machine, 200-300W

Die Board Laser Cutting Machine, 200-300W

-

T10 LED Fluorescent Tube, YK-B1020J

T10 LED Fluorescent Tube, YK-B1020J

-

Wall Panel Forming Machine

Wall Panel Forming Machine

-

Corrugated Sheet Forming Machine

Corrugated Sheet Forming Machine

-

T5 LED Fluorescent Tube, YK-B1091, YK-B1092, YK-B1093, YK-B1094

T5 LED Fluorescent Tube, YK-B1091, YK-B1092, YK-B1093, YK-B1094