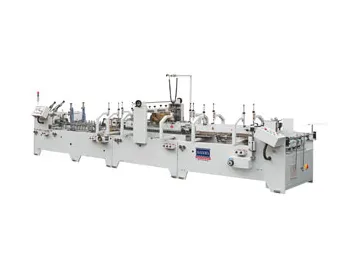

MY-800H Automatic Die Cutting and Foil Stamping Machine

The MY-800H automatic die cutting and foil stamping machine is a high-tech mechatronic product adopting computer control. It also adopts the following high and new technology such as multimedia technology, gate array, AC servo system etc. to realize automation of the full process from paper feeding to die cutting, foil stamping, pressure boosting, depressurization, foil winding, paper discharging, skipping, counting, heating, pre-heating, failure display and inspection.

The automatic die cutting and foil stamping machine is mainly applied in die cutting, creasing, foil stamping and cold and hot pressing of the paper box, Logo in packaging industry. Because of the unique performance of this machine, it can satisfy various requirements of our customers.This kind of machine features easy operation, safety and reliability, high speed, high pressure, high precision and good quality so that it is highly relied on by the users. It also adopts high precision intermittent mechanism and positioning system to realize more stable running and more precise positioning.

This machine adopts PLC electrical control system with electronic CAM so that the process control of the machine motion is more precise and the adjustment is more convenient.

The human-computer monitoring and display system can show the running situation of the machine clearly. It can also carry out failure display and removal perfectly, thus realizing human-computer communication.

It also uses imported pneumatic clutch which features long service life, low noise and stable clutch and braking. It adopts pneumatic locking unit as well, enabling convenient, fast, safe and reliable die locking.

The main electrical element, bearing, fastener, chain of the whole machine are all imported from the famous brands to ensure precision and service life.

All the electrical elements are certified by CE. Meanwhile, various protective covers can meet the requirements of CE. So they are safe and reliable.

The lubricating system of the main transmission adopts strong wind cooling unit, so the efficiency of the machine under high temperature for long period can be improved.

The stepping control system of the foil stamping adopts imported servo motor which features synchronous foil rewinding and releasing, constant tension and more precise transmission skipping.

There are 12 heating zones of which the temperature setting and constant temperature control can be carried out independently to satisfy different requirements for foil stamping.

Technical Specification:

The automatic die cutting and foil stamping machine is mainly applied in die cutting, creasing, foil stamping and cold and hot pressing of the paper box, Logo in packaging industry. Because of the unique performance of this machine, it can satisfy various requirements of our customers.This kind of machine features easy operation, safety and reliability, high speed, high pressure, high precision and good quality so that it is highly relied on by the users. It also adopts high precision intermittent mechanism and positioning system to realize more stable running and more precise positioning.

This machine adopts PLC electrical control system with electronic CAM so that the process control of the machine motion is more precise and the adjustment is more convenient.

The human-computer monitoring and display system can show the running situation of the machine clearly. It can also carry out failure display and removal perfectly, thus realizing human-computer communication.

It also uses imported pneumatic clutch which features long service life, low noise and stable clutch and braking. It adopts pneumatic locking unit as well, enabling convenient, fast, safe and reliable die locking.

The main electrical element, bearing, fastener, chain of the whole machine are all imported from the famous brands to ensure precision and service life.

All the electrical elements are certified by CE. Meanwhile, various protective covers can meet the requirements of CE. So they are safe and reliable.

The lubricating system of the main transmission adopts strong wind cooling unit, so the efficiency of the machine under high temperature for long period can be improved.

The stepping control system of the foil stamping adopts imported servo motor which features synchronous foil rewinding and releasing, constant tension and more precise transmission skipping.

There are 12 heating zones of which the temperature setting and constant temperature control can be carried out independently to satisfy different requirements for foil stamping.

Technical Specification:

| Model | MY-800H |

| Max.Paper Size | 810*610mm |

| Min. Paper Size | 350*230mm |

| Max.Die cutting Size | 790*600mm |

| Max. Stamping Range | 760*540mm |

| Max.Die cutting Speed | 7500s/h |

| Max.Stamping Speed | 7000s/h |

| Max.Feeding Pile | 850mm |

| Max.Delivery Pile | 800mm |

| Sheet Thickness | Cardboard:0.1-1.5mm Corrugated board:≤4mm |

| Die-Cutting Precision | ±0.1mm |

| Stamping Temperature | 0~200℃ |

| Heating Plate Zone Number | 12 |

| NO. Of Foil Rollers | 3 Vertical and 2 Horizontal |

| Max. Length | 1800~2200m |

| Max.Pressure | 250t |

| Total Weight | 12.5t |

| Heating Plate Zone Power | 18kw |

| Total Power | 36kw |

| Overall Dimension | 6470*3550*2160mm |

| Max. foil width | 760mm |

| Min. foil width | 25mm |

| Max. length of pull foil | 600mm |

| Max. pull foil roll diameter | φ200mm |

| Max. foil width | 540mm |

| Min. foil width | 25mm |

| Max. length of pull foil | 800mm |

| Max. pull foil roll diameter | φ220mm |

Scan QR to Read

Links:https://globefindpro.com/products/15339.html

Links:https://globefindpro.com/products/15339.html

Recommended Products

-

Semi-Automatic Die Cutting and Creasing Machine

Semi-Automatic Die Cutting and Creasing Machine

-

Box Crash Lock Bottom Folder Gluer Machine

Box Crash Lock Bottom Folder Gluer Machine

-

Corrugated Cardboard Sheet Stacker

Corrugated Cardboard Sheet Stacker

-

UV Spot Coating Machine

UV Spot Coating Machine

-

Automatic Corrugated Carton Folder Gluer

Automatic Corrugated Carton Folder Gluer

-

High Speed UV Spot Coating Machine

High Speed UV Spot Coating Machine

-

Crash Lock Bottom Folder Gluer Machine

Crash Lock Bottom Folder Gluer Machine

-

Pre Fold Crash Lock Bottom Folder Gluer

Pre Fold Crash Lock Bottom Folder Gluer

-

MY-1050T Automatic Die Cutting and Foil Stamping Machine

MY-1050T Automatic Die Cutting and Foil Stamping Machine

-

Semi-auto Stitching Machine

Semi-auto Stitching Machine

-

MY-760 Automatic Die Cutting and Creasing Machine

MY-760 Automatic Die Cutting and Creasing Machine

-

Carton Die Cutting and Stripping Machine

Carton Die Cutting and Stripping Machine

Hot Products