Z Purlin Forming Machine

Equipment Configuration

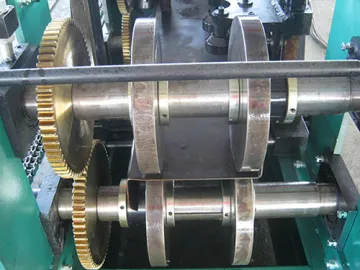

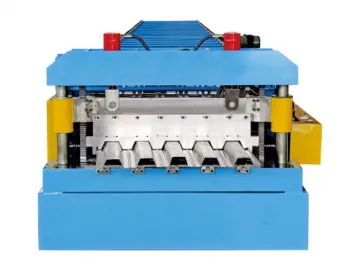

Feeding device, transmission, main machine and forming roller (including guide table), cutting (after roll forming) device, hydraulic system, electric control system, run out table, etc. Main rack of the machine is processed on the planer type milling machine.

Production process

Manually de-coiling →Guiding & feeding & correcting→ Roll forming → Cutting after roll forming → Finished product

| Number | o | b | c | t |

| 1 | 150 | 62 | 57 | 2-3 |

| 2 | 160 | 62 | 57 | 2-3 |

| 3 | 180 | 77 | 72 | 2-3 |

| 4 | 200 | 77 | 72 | 2-3 |

| 5 | 240 | 77 | 72 | 2-3 |

| 6 | 250 | 77 | 72 | 2-3 |

| 7 | 300 | 92 | 87 | 2-3 |

Scan QR to Read

Links:https://globefindpro.com/products/15809.html

Links:https://globefindpro.com/products/15809.html

Recommended Products

-

Curved Sheet Screw Jointed Equipment

Curved Sheet Screw Jointed Equipment

-

BH-1000-700 Arched Roof Sheet Forming Machine

BH-1000-700 Arched Roof Sheet Forming Machine

-

Steel Decking Roll Forming Machine

Steel Decking Roll Forming Machine

-

KR24 Roll Forming Machine

KR24 Roll Forming Machine

-

C Purlin Forming Machine

C Purlin Forming Machine

-

Shearing Machine

Shearing Machine

-

Concealed Roof Sheet Forming Machine

Concealed Roof Sheet Forming Machine

-

Corrugated Roof Sheet Forming Machine

Corrugated Roof Sheet Forming Machine

-

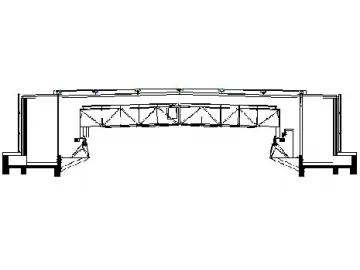

Trussing Type Window Cleaning Machine

Trussing Type Window Cleaning Machine

-

Highway Guardrail Roll Forming Machine

Highway Guardrail Roll Forming Machine

-

Aluminum Alloy Suspended Platform, Cradle, Swing Stage

Aluminum Alloy Suspended Platform, Cradle, Swing Stage

-

BH-HP -220B PU Foam Spray Equipment

BH-HP -220B PU Foam Spray Equipment