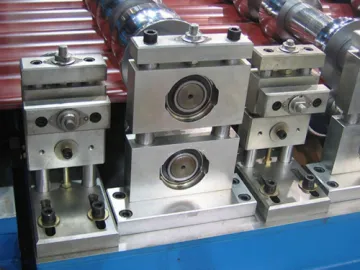

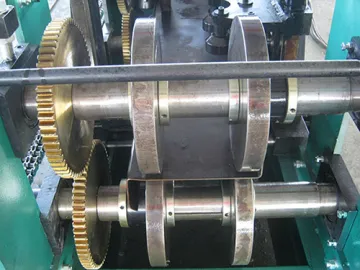

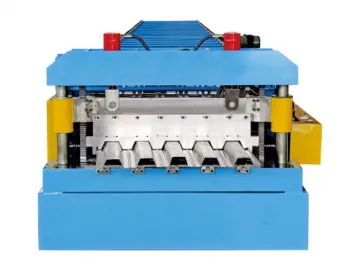

Corrugated Roof Sheet Forming Machine

Bohai has been engaged in the research and manufacture of roll forming machines that include corrugated roof sheet forming machine, 840 corrugated sheet roll forming machine, sandwich panel forming machine , flat sheet bending machine, etc. With more than 20 years of experience in this line, we know how to produce a productive and durable corrugated roof sheet forming machine at a low cost. Please contact us for your corrugated roof sheet forming machine needs.

Technological Process

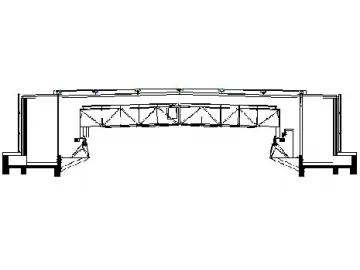

Passively De-coiling → Guiding & Feeding Material → Roll Forming → Cutting-to-length → Output Panel

| No. | Item | Qty. |

| 1 | Passive d e-coi ler | 1 piece |

| 2 | Roll forming machine | 1 piece |

| 3 | Hydraulic cutting blade | 1 set |

| 4 | Hydraulic station | 1 piece |

| 5 | Computer control c ounter | 1 piece |

| 6 | Run out table | 3 pieces |

Our product can be provided to make the sheet in different coil width and height of wave. The profile drawing is available in replying the inquiry of customers.

Scan QR to Read

Links:https://globefindpro.com/products/15807.html

Links:https://globefindpro.com/products/15807.html

Recommended Products

-

Concealed Roof Sheet Forming Machine

Concealed Roof Sheet Forming Machine

-

Z Purlin Forming Machine

Z Purlin Forming Machine

-

Curved Sheet Screw Jointed Equipment

Curved Sheet Screw Jointed Equipment

-

BH-1000-700 Arched Roof Sheet Forming Machine

BH-1000-700 Arched Roof Sheet Forming Machine

-

Steel Decking Roll Forming Machine

Steel Decking Roll Forming Machine

-

KR24 Roll Forming Machine

KR24 Roll Forming Machine

-

Trussing Type Window Cleaning Machine

Trussing Type Window Cleaning Machine

-

Highway Guardrail Roll Forming Machine

Highway Guardrail Roll Forming Machine

-

Aluminum Alloy Suspended Platform, Cradle, Swing Stage

Aluminum Alloy Suspended Platform, Cradle, Swing Stage

-

BH-HP -220B PU Foam Spray Equipment

BH-HP -220B PU Foam Spray Equipment

-

Highway Guardrail Roll Forming Machine

Highway Guardrail Roll Forming Machine

-

LTD Hoist Motor / Winch

LTD Hoist Motor / Winch

Hot Products