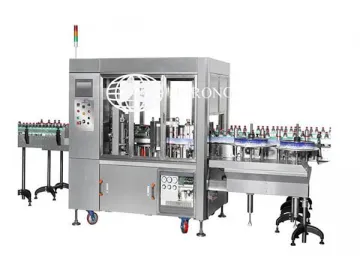

3-in-1 Automatic Carbonated Beverage Bottling Machine

This series of monoblock bottling machine is suitable for filling all kinds of carbonated drinks into PET or glass bottles. Our carbonated beverage filling machines are available in various speed ranging from 5,000 to 30,000 bottles per hour.

Videos Basic Information Bottle type: PET bottles, glass bottles Cap type: plastic screw caps, aluminum caps, crown caps Bottle volume: 200-2000ml Washing method: adopting newly developed mechanical valve that precisely controls the rinsing fluid, without leakage of water Filling method: isobaric filling system Capping method:Plastic cap: magnetic clutch capping head is used for closing of plastic screw caps, the torque is easily adjustable for reliable cap closing quality

Crown cap: capping force can be easily adjusted, ceramic material is used to protect caps from being damaged

Aluminum cap: the cap closing system forms threads and seals aluminum caps onto bottles with exceptional ease and high tightness Specifications

| Model | Production output (500ml PET bottle) | Overall dimensions (L×W×H) | Power | Weight |

| JR18-18-6D | 5000 b/h | 2800×2050×2200mm | 3 kW | 5500 kg |

| JR24-24-8D | 8000 b/h | 3100×2250×2800mm | 4 kW | 7000 kg |

| JR32-32-10D | 10000 b/h | 3600×2900×2900mm | 5.5 kW | 8500 kg |

| JR40-40-10D | 13000 b/h | 4250×3250×2900mm | 7.5 kW | 10000 kg |

| JR50-50-12D | 16000 b/h | 5200×3700×3000mm | 11 kW | 14000 kg |

| JR60-60-15D | 20000 b/h | 6300×4400×3000mm | 11 kW | 17000 kg |

| JR72-72-16D | 26000 b/h | 6900×4950×3000mm | 11 kW | 18000 kg |

| JR80-80-18D | 30000 b/h | 7600×5100×3000mm | 15 kW | 20000 kg |

Air conveyor transfers bottles into the machine with bottle neck clamping and bottle suspending methods, which can ensure fast bottle conveying without causing bottle deformation. The stainless steel gripper is featured by simple structure and easy adjustment, and the small contact surface minimizes the secondary contamination of bottle neck.

Filling Station

Isobaric filling valve is adopted to provide high filling speed and accurate liquid level. Carbonated beverage filler uses stepless speed regulation and bottle guiding system has a simple structure, it means bottle size can be changed in an efficient and timely manner.

Tags: craft beverage bottling equipment liquid filling machines bottle washer filler capper machine carbonated beverage bottling machineLinks:https://globefindpro.com/products/1692.html

-

Glass Four Edge Grinding Machine

Glass Four Edge Grinding Machine

-

Water Treatment System

Water Treatment System

-

Non-Carbonated Drink Canning Machine

Non-Carbonated Drink Canning Machine

-

Glass Four Edge Grinding Machine

Glass Four Edge Grinding Machine

-

Prefabricated Commercial Building, Luxury Series

Prefabricated Commercial Building, Luxury Series

-

Pulpers

Pulpers

-

Tray Former Box Making Machine, RPM-03

Tray Former Box Making Machine, RPM-03

-

Tube-in-Tube Sterilizer

Tube-in-Tube Sterilizer

-

1000mm Stretch Film Machine

1000mm Stretch Film Machine

-

Automatic Shrink Wrapping Machine

Automatic Shrink Wrapping Machine

-

3-in-1 Automatic Still Beverage Bottling Machine

3-in-1 Automatic Still Beverage Bottling Machine

-

OPP/BOPP Labeling Machine

OPP/BOPP Labeling Machine