Pulpers

Our hydraulic pulpers can slush pulp board, broken paper and waste paper into pulp. Apart from processing paper products, the pulpers can also be used in the production of wet-laid nonwovens to break down the fiber bundle into individual fibers. How can the pulping machines do that? The answers lie in their mechanical configuration. Take our vertical pulper as an example. The pulpling system consists of a tub with a rotor located in the bottom of the tub, on which there are some blades. A fixed plate with multiple blades is arranged at the bottom of the rotor. The rotor is driven by an electrical motor through a rotating axis. Apart from being connected through an axis, the rotor can also be linked through a resilient coupling, a rigid coupling and a gear reducer.

Drum Pulper

Tags hydro pulper

paper pulping machine

pulping systems

pulper rotor

high-consistency pulper

paper pulp machines for pulp mill

Links:https://globefindpro.com/products/1698.html

-

Refiners for Pulp Refining

Refiners for Pulp Refining

-

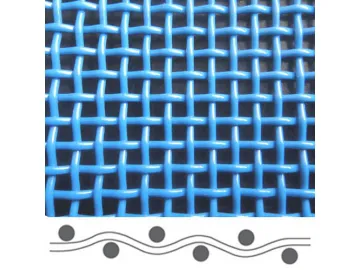

Polyester Meshes for Paper Machine

Polyester Meshes for Paper Machine

-

Prefabricated Holiday Lodge, Luxury Series

Prefabricated Holiday Lodge, Luxury Series

-

Cylinder Mould for Paper Machine

Cylinder Mould for Paper Machine

-

Prefabricated Public Toilets, 15CS

Prefabricated Public Toilets, 15CS

-

Pressure Screens & Screen Baskets for Stock Preparation

Pressure Screens & Screen Baskets for Stock Preparation

-

Prefabricated Commercial Building, Luxury Series

Prefabricated Commercial Building, Luxury Series

-

Glass Four Edge Grinding Machine

Glass Four Edge Grinding Machine

-

Non-Carbonated Drink Canning Machine

Non-Carbonated Drink Canning Machine

-

Water Treatment System

Water Treatment System

-

Glass Four Edge Grinding Machine

Glass Four Edge Grinding Machine

-

3-in-1 Automatic Carbonated Beverage Bottling Machine

3-in-1 Automatic Carbonated Beverage Bottling Machine