Non-Carbonated Drink Canning Machine

Automatic Can Filling Seaming Machine for Juice and Tea Automatic Can Filling Seaming Machine for Juice and Tea

Details Filling Station  Seaming Station

Seaming Station

Our non-carbonated drink canning machine is designed for filling and seaming of tinplate cans with non-carbonated beverages such as fruit juices, teas and protein drinks.

Specifications| Model | Production output (330ml can) | Overall dimensions (L×W×H) | Power | Weight |

| DGC12-4 | 30-170 c/m | 2700×1400×1900MM | 5.5 kW | 3100 kg |

| DGC18-4 | 30-250 c/m | 3050×1750×1900 MM | 5.5 kW | 3800 kg |

| DGC24-6 | 50-300 c/m | 2750×1790×1900 MM | 7.5 kW | 4500 kg |

| DGC36-6 | 50-400 c/m | 3175×2230×1900 MM | 7.5 kW | 5000 kg |

| DGC48-8 | 100-600 c/m | 3650×2450×2100 MM | 11 kW | 7500 kg |

| DGC72-12 | 100-800 c/m | 3850×2450×2100 MM | 15 kW | 9500 kg |

The can filler for non-carbonated beverage adopts gravity filling method, providing more stable and faster filling process thereby translating to a better productivity and yielding a higher profit than that of conventional liquid filler with equivalent capacity. The filling unit is featured by high automation level, allowing operator to control the system with ease.

Filled cans are conveyed to the seamer where can lids are placed and attached to the can bodies, and the cans are tightly seamed.

Configurations Frequency converter: Siemens PLC: Siemens Circuit breaker: Siemens Circuit contactor: Siemens Thermal relay: Siemens Proximity switch: Omron Fiber switch: Omron Touch screen:: Kinco/Siemens Pneumatic components: AIRTAC/FESTO Stainless Steel: POSCO Tags: can fillers can filling machines non-carbonated beverage machinery beverage filling packaging plant aluminum can filling lines

Scan QR to Read

Links:https://globefindpro.com/products/1695.html

Links:https://globefindpro.com/products/1695.html

Recommended Products

-

Glass Four Edge Grinding Machine

Glass Four Edge Grinding Machine

-

Prefabricated Commercial Building, Luxury Series

Prefabricated Commercial Building, Luxury Series

-

Pulpers

Pulpers

-

Refiners for Pulp Refining

Refiners for Pulp Refining

-

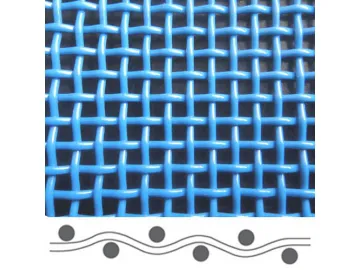

Polyester Meshes for Paper Machine

Polyester Meshes for Paper Machine

-

Prefabricated Holiday Lodge, Luxury Series

Prefabricated Holiday Lodge, Luxury Series

-

Water Treatment System

Water Treatment System

-

Glass Four Edge Grinding Machine

Glass Four Edge Grinding Machine

-

3-in-1 Automatic Carbonated Beverage Bottling Machine

3-in-1 Automatic Carbonated Beverage Bottling Machine

-

Tray Former Box Making Machine, RPM-03

Tray Former Box Making Machine, RPM-03

-

Tube-in-Tube Sterilizer

Tube-in-Tube Sterilizer

-

1000mm Stretch Film Machine

1000mm Stretch Film Machine