Vacuum Capping Machine, FDB

This vacuum capping machine is specially used for capping wide-mouth bottles, such as fermented tofu bottles, pickle bottles, jam jars.

The vacuum capping machinery is a multi-function machine integrated with automatic cap feeding, placing, and capping. It features simple operation, and high production speed. This glass bottle capping machine is mainly used for three, four, and six twist caps. The capping operation is completed by pressing the cap with two belts of different speeds. Before capping, high temperature steam is firstly blown to heat the mouths of the bottles, then perform capping immediately. According to the principle of thermal expansion, vacuum inside the bottle is formed after the steam is cooled. Therefore, vacuum capping is achieved.

| Type | FDB |

| Capacity | 3000-6000 bottles/hour (*according to the cap size ) |

| Cap/jar diameter | ⌀30- ⌀90mm |

| Bottle/jar diameter / height | Diameter: ⌀30- ⌀100mm; Height: 65-260mm |

| Steam consumption | 180-230kg/h |

| Steam pressure | ≤0.4MPa / steam requirement:182-227 kg/h |

| Max. vacuum degree | 67kPa(502mmHg) |

| Closure types | Three twist cap, four twist cap, six twist cap & press- twist cap |

| Vacuum in the bottle | 66cm-HG |

| Power supply | 220V, 50Hz, 3.12kW |

| Machine size / weight | 3000×1000×2000mm(L×W×H) / around 1100kg |

Links:https://globefindpro.com/products/1788.html

-

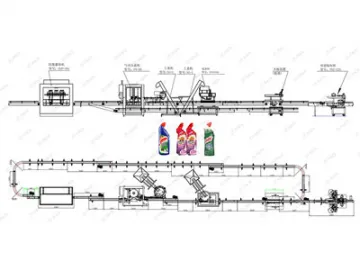

100ml-1000ml Corrosive Liquid Filling Line (Harpic Toilet Cleaner Packaging)

100ml-1000ml Corrosive Liquid Filling Line (Harpic Toilet Cleaner Packaging)

-

1L-5L Agrochemicals Filling Line

1L-5L Agrochemicals Filling Line

-

50ml -1000ml Pesticide Filling Line

50ml -1000ml Pesticide Filling Line

-

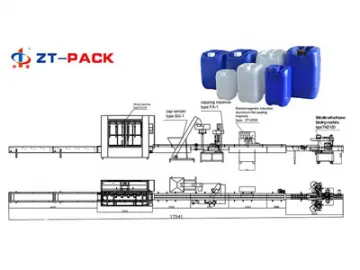

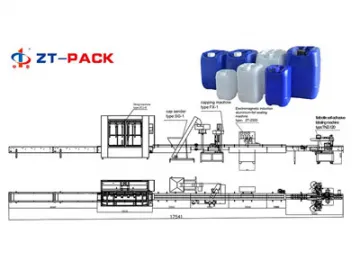

4L-30L Drum Gallons Engine Oil Filling Line

4L-30L Drum Gallons Engine Oil Filling Line

-

Fresh Noodle Machines

Fresh Noodle Machines

-

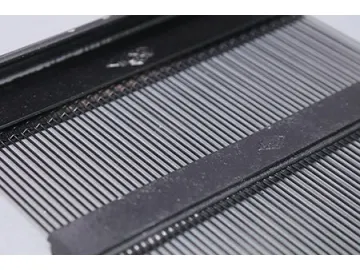

Self-Cleaning Piano Wire Screen

Self-Cleaning Piano Wire Screen

-

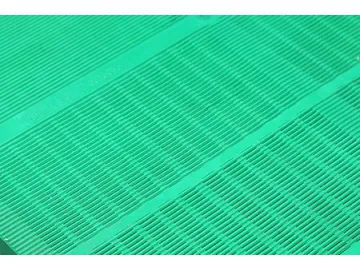

Polyurethane Screen

Polyurethane Screen

-

0.5L-7L Engine Oil Filling Line

0.5L-7L Engine Oil Filling Line

-

Soya Sauce Vinegar Filling Line

Soya Sauce Vinegar Filling Line

-

4L-30L Drum Gallons Liquid Filling Line

4L-30L Drum Gallons Liquid Filling Line

-

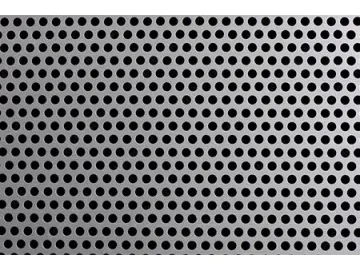

Perforated Plate Screen

Perforated Plate Screen

-

Vaseline Jelly Wax Filling & Packaging Line

Vaseline Jelly Wax Filling & Packaging Line