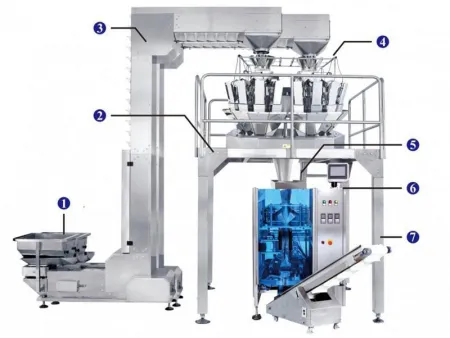

JW-MIX1 Vertical Form Fill and Seal Packaging Line with 10 Head Weigher

Vibratory feeder

Working platform

Z-shaped elevating conveyor

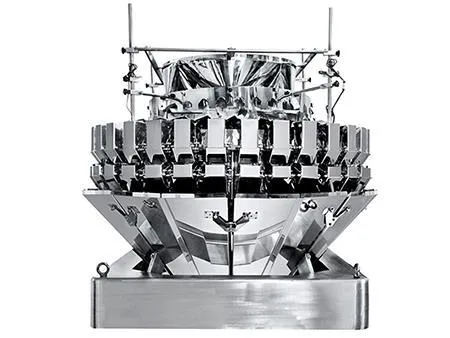

10 heads weigher

Freefall metal detector

Vertical form fill and seal machine

Finished product conveyor

Range of application

Applicable products: All types of particles, pieces, strips, round or irregular shaped products such as candies, seeds, pet foods, puffed foods, hardware, rubber parts and more.

Pouch types

① 3-side seal pouch

② 4 side seal pouch

③ Flat pouch ④ Standard stand-up pouch

⑤ Back sealed pouch

⑥ Quad seal gusseted pouch

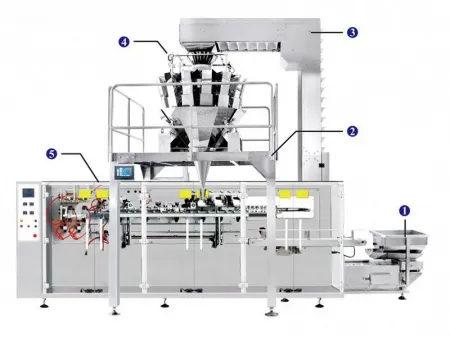

Weighing and packing line for mixed products solutions

Selective assembly equipment

Check weigher Metal Detectors Combined metal detector and check weigher Thermal Transfer Overprinter Count verification machine Conveyor equipment Accessories

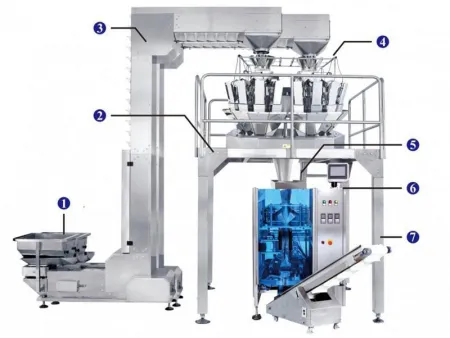

Working platform

Z-shaped elevating conveyor

10 heads weigher

Freefall metal detector

Vertical form fill and seal machine

Finished product conveyor

The JW-MIX1 weighing and packing line for mixed products is composed of the vibratory feeder, working platform, Z-shaped elevating conveyor, 10 heads weigher, free-fall metal detector, vertical form fill seal machine and finished product conveyor in order to automatically complete the feeding, dosing, weighing, bag forming and filling, bag sealing, label printing, mixing and discharging processes.

This production line is equipped with 2 multihead weighers to enhance the production efficiency, both of which are controlled using the same control panel so that the highest weighing accuracy is guaranteed.

Range of application

Applicable products: All types of particles, pieces, strips, round or irregular shaped products such as candies, seeds, pet foods, puffed foods, hardware, rubber parts and more.

Pouch types

① 3-side seal pouch

② 4 side seal pouch

③ Flat pouch ④ Standard stand-up pouch

⑤ Back sealed pouch

⑥ Quad seal gusseted pouch

Weighing and packing line for mixed products solutions

| Model series | Standard configuration | Maximum packing speed | Maximum packing weight | Film width | Film thickness | Multihead weigher power | Packing machine power | Voltage |

| 2 in 1 mixing | 20 heads weigher | 60p/min | 2000g | 180-520mm | 0.04mm-0.15mm | 990W | 3.4KW | 220v |

| 3 in 1 mixing | 24 heads weigher | 60p/min | 300g | 180-520mm | 0.04mm-0.15mm | 990W | 3.4KW | 220v |

| 4 in 1 mixing | 24 heads weigher | 60p/min | 240g | 180-520mm | 0.04mm-0.15mm | 990W | 3.4KW | 220v |

| 4 in 1 mixing using 32 heads weigher | 32 heads weigher | 60p/min | 400g | 180-520mm | 0.04mm-0.15mm | 990W | 3.4KW | 220v |

| 10 in 1 mixing using 10 heads weigher | 10 heads linear weigher | 50p/min | 1000g | 180-520mm | 0.04mm-0.15mm | 990W | 3.4KW | 220v |

Note: Kenwei provides custom cup filling and capping line if you have specific requirements.

Selective assembly equipment

Check weigher Metal Detectors Combined metal detector and check weigher Thermal Transfer Overprinter Count verification machine Conveyor equipment Accessories

Scan QR to Read

Links:https://globefindpro.com/products/23051.html

Links:https://globefindpro.com/products/23051.html

Recommended Products

-

Stick Shaped Weigher for free flow products (Optional 10 heads, 14 heads; 3-200g, 10-1000g, 10-1500g, 100-3000g; 0.5L, 2.5L, 5L)

Stick Shaped Weigher for free flow products (Optional 10 heads, 14 heads; 3-200g, 10-1000g, 10-1500g, 100-3000g; 0.5L, 2.5L, 5L)

-

No-Spring Weigher for free flow products (Optional 10 heads, 14 heads; 10-1000g, 10-1500g; 1.6L)

No-Spring Weigher for free flow products (Optional 10 heads, 14 heads; 10-1000g, 10-1500g; 1.6L)

-

Z-Shaped Bucket Elevator

Z-Shaped Bucket Elevator

-

JW-A32 for Mixed Ingredients (32 heads; 5-240g; 0.5L)

JW-A32 for Mixed Ingredients (32 heads; 5-240g; 0.5L)

-

Takeaway Conveyor

Takeaway Conveyor

-

Combined Metal Detector with Check Weigher

Combined Metal Detector with Check Weigher

-

JW-JDC2 Form-Fill-Sealing Systems with Horizontal Bagger, 12 heads weigher

JW-JDC2 Form-Fill-Sealing Systems with Horizontal Bagger, 12 heads weigher

-

JW-MIX2 Horizontal Weighing and Packing Line for Mixed Products with 10 Head Weigher

JW-MIX2 Horizontal Weighing and Packing Line for Mixed Products with 10 Head Weigher

-

High Precision Compact Weigher for free flow products (Optional 10 heads, 14 heads; 5-60g, 5-100g, 5-200g; 0.3L, 0.5L)

High Precision Compact Weigher for free flow products (Optional 10 heads, 14 heads; 5-60g, 5-100g, 5-200g; 0.3L, 0.5L)

-

JW-AHS for free flow products (Optional 20 heads; 10-100g; 1.6L, 2.5L)

JW-AHS for free flow products (Optional 20 heads; 10-100g; 1.6L, 2.5L)

-

JW-A16 for free flow products (16 heads; 5-200g; 0.5L)

JW-A16 for free flow products (16 heads; 5-200g; 0.5L)

-

Automatic Carton Box Packing Machine

Automatic Carton Box Packing Machine

Hot Products