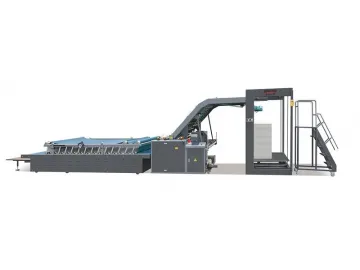

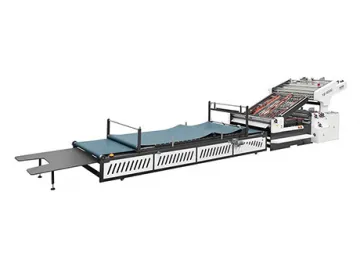

Semi-Automatic Sheet to Sheet Laminator, BG Series

The Semi automatic flute sheet to sheet laminating(mounting) machine(high speed) is suitable for the laminating of 175g-500g color printing paper and A/B/C/D/E/F corrugated paper, and is also suitable for the laminating of 175g-500g color printing paper and gray board paper. The machine adopts a bottom sheet suction feeding unit. The paper stacking height is 1.5m, and the length of the paper that can be laminated is 0-90m per minute. Compared with traditional laminating machines, this type of sheet to sheet laminating(mounting) machinemakes paper feeding easier and bottom sheet feeding more convenient.

| Max sheet | 1300*1250mm |

| Min sheet | 350X350mm |

| Total power | 8.5kw |

| Max speed | 0-90m/min |

| Measurement | 10*1.97*2.3M |

| Machine weight | 4500kg |

| Max sheet | 1450*1250mm |

| Min sheet | 350X350mm |

| Total power | 9.5kw |

| Max speed | 0-90m/min |

| Measurement | 10*2.02*2.3M |

| Machine weight | 5000kg |

| Max Sheet | 1650X1250mm |

| Min Sheet | 350X350mm |

| Total Power | 11kw |

| Max Speed | 0-90m/min |

| Measurement | 10*2.25*2.3M |

| Machine Weight | 5500kg |

(The parameters of semi-automatic flute sheet to sheet laminating(mounting) machine(high speed) can be changed according to the actual needs of the customers.)

Features According to the speed of the manual feeding paper, the bottom sheet is automatically fed by the suction pump. The front gauge positioning system makes the positioning of the upper paper and the bottom sheet accurate, and can ensure that the bottom sheet never advances. The part of the upper paper beyond the bottom sheet can be adjusted in time. Equipped with automatic glue replenishment system, the glue can be recycled and saved, which saves production costs. The line speed of metering roller is designed to ensure uniform glue amount and avoid the glue throwing. The separate water tank is used to ensure the back of the bottom sheet is dry. Product packageLinks:https://globefindpro.com/products/25516.html

-

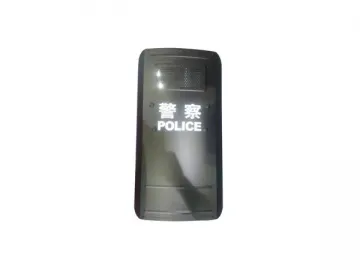

Aluminum Anti-Riot Shield (ARS-A9050)

Aluminum Anti-Riot Shield (ARS-A9050)

-

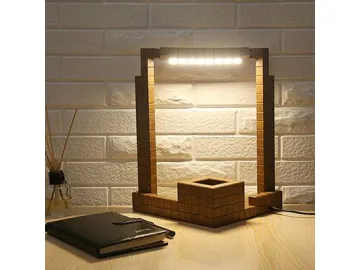

Modular LED Lamp

Modular LED Lamp

-

Manual-Automatic Dual-use Sheet-to-sheet Laminating/mounting Machine

Manual-Automatic Dual-use Sheet-to-sheet Laminating/mounting Machine

-

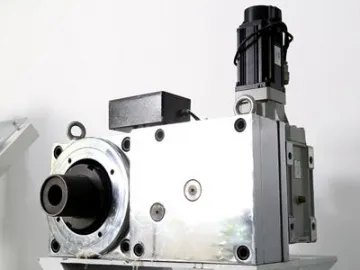

Continuous screen changer with Backflush System

Continuous screen changer with Backflush System

-

Police Baton

Police Baton

-

Basic info:

Basic info:

-

Basic info:

Basic info:

-

Advanced Composite Bulletproof Helmet (ACBH-2000)

Advanced Composite Bulletproof Helmet (ACBH-2000)

-

Non-Nail PASGT Aramid Bulletproof Helmet (PASGT-A400)

Non-Nail PASGT Aramid Bulletproof Helmet (PASGT-A400)

-

Hanging Framed LED Crystal Lightbox Display

Hanging Framed LED Crystal Lightbox Display

-

MICH Advanced Aramid Bulletproof Helmet, Ballistic Helmet

MICH Advanced Aramid Bulletproof Helmet, Ballistic Helmet

-

Anti-Riot Bulletproof Suit (RCS2-BA3A)

Anti-Riot Bulletproof Suit (RCS2-BA3A)