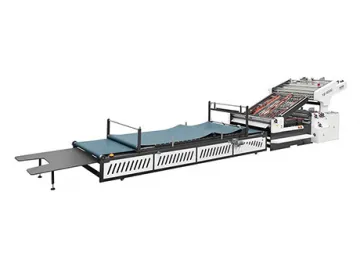

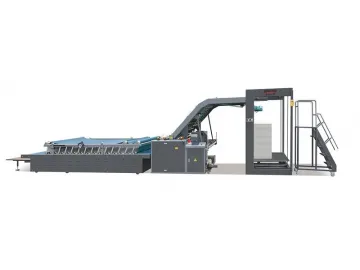

Manual-Automatic Dual-use Sheet-to-sheet Laminating/mounting Machine

Automatic-Manual Laminating Machine - Manual or automatic top sheet feeding can be selected according to actual production conditions. The customer can choose the automatic paper feeding mode if the quantity is large or the paper has good quality, otherwise, can choose manual feeding mode. No matter how many sheets the customer need to laminate one time, or whether the paper has good quality, our machine can handle it.

| Max Sheet size | 1300*1250mm |

| Min Sheet size | 400X400mm |

| Top sheet thickness | 150GSM-600GSM |

| Max speed | 6000sheets/hour |

| Fitting precision | ±1.5mm |

| Measurement | 9500*2000*2400mm |

| Machine weight | 4500kg |

| Machine power | 10KW/380V |

| Bottom sheet thickness | A, B, C, E, F, AB, BB, BC, EE/ Corrugated paper/ Industry cardboard |

| Max Sheet size | 1450*1250mm |

| Min Sheet size | 400X400mm |

| Top sheet thickness | 150GSM-600GSM |

| Max speed | 6000sheets/hour |

| Fitting precision | ±1.5mm |

| Measurement | 9500*2200*2400mm |

| Machine weight | 5000kg |

| Machine power | 11KW/380V |

| Bottom sheet thickness | A, B, C, E, F, AB, BB, BC, EE/ Corrugated paper/ Industry cardboard |

| Max Sheet size | 1650X1450mm |

| Min Sheet size | 400X400mm |

| Top sheet thickness | 150GSM-600GSM |

| Max speed | 6000sheets/hour |

| Fitting precision | ±1.5mm |

| Measurement | 9500*2400*2400mm |

| Machine weight | 5500kg |

| Machine power | 12KW/380V |

| Bottom sheet thickness | A, B, C, E, F, AB, BB, BC, EE/ Corrugated paper/ Industry cardboard |

(The parameters of the automatic & manual flute sheet to sheet laminating(mounting) machinecan be changed according to the actual needs of the customers.)

Features The front gauge positioning system makes the positioning of the upper paper and the bottom sheet accurate, and can ensure that the bottom sheet never advances. The part of the upper paper beyond the bottom sheet can be adjusted in time. The feeding unit enables the high speed and smoothness of paper feeding and improves the production efficiency of the sheet to sheet laminating(mounting) machineduring the operation process, regardless of thick paper or thin paper. The bottom sheet system uses suction to automatically feed paper. The bottom sheet system ensures that paper can be smoothly discharged while the machine is running. Adopt electrical components of well-known brands, such as Schneider, Siemens, etc., to ensure the stability of the circuit system. Equipped with automatic glue replenishment system, the glue can be recycled and saved, which saves production costs. The line speed of metering roller is designed to ensure uniform glue amount and avoid the glue throwing. The floating movable press ensures that the corrugated paper will not be deformed after fitting process, and that the cardboard is flat and straight. The separate water tank is used to ensure the back of the bottom sheet is dry. The pressure regulation system adopts a single-side pressure adjustment to ensure that the pressure on the left and right sides is consistent. The machine can adjust the specifications of the bottom sheet in one step when changing the paper specifications. Product package

Scan QR to Read

Links:https://globefindpro.com/products/25520.html

Links:https://globefindpro.com/products/25520.html

Recommended Products

-

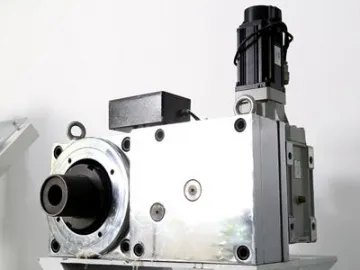

Continuous screen changer with Backflush System

Continuous screen changer with Backflush System

-

Police Baton

Police Baton

-

Basic info:

Basic info:

-

Fruit & Vegetable Processing Line

Fruit & Vegetable Processing Line

-

Level IV Ballistic Plate BP-07D, Body Armor Plate

Level IV Ballistic Plate BP-07D, Body Armor Plate

-

Ballistic Blanket

Ballistic Blanket

-

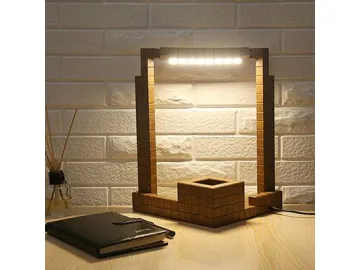

Modular LED Lamp

Modular LED Lamp

-

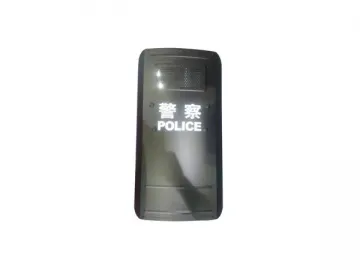

Aluminum Anti-Riot Shield (ARS-A9050)

Aluminum Anti-Riot Shield (ARS-A9050)

-

Semi-Automatic Sheet to Sheet Laminator, BG Series

Semi-Automatic Sheet to Sheet Laminator, BG Series

-

Basic info:

Basic info:

-

Advanced Composite Bulletproof Helmet (ACBH-2000)

Advanced Composite Bulletproof Helmet (ACBH-2000)

-

Non-Nail PASGT Aramid Bulletproof Helmet (PASGT-A400)

Non-Nail PASGT Aramid Bulletproof Helmet (PASGT-A400)