Cast Perforated Film Line, PE Breathable Film Machine

Film weight range 16-50gsm

Net film width From 1000mm to 2000mm

Perforation pattern Round, triangle, square, pentagon, double perforation or upon request Applications

The PE perforated film is used as the top sheet of sanitary napkin, baby diaper; food packaging such as butter wrapping, meat absorbent pad, and agricultural application.

Line Layout Technical Parameters

| Model No. | DF90-1400 | DF110-1800 | DF120-2000 |

| Screw Dia. | 90mm | 110mm | 120mm |

| Die Width | 1700mm | 2100mm | 2300mm |

| Film Width | 1400mm | 1800mm | 2000mm |

| Film Weight | 16-50gsm | 16-50gsm | 16-50gsm |

| Production Speed | 30-50m/min | 30-50m/min | 30-50m/min |

* Remarks: Machine dimensions can be customized upon request.

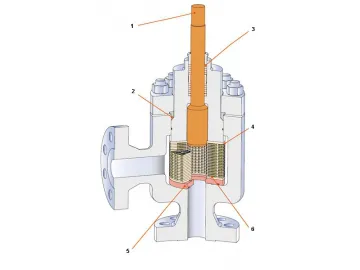

OverviewThe line produces micro-perforated film by using the materials of polyethylene. While the melt resin comes out of extrusion die, it is formed into film and vacuum perforated at the same time. Those micro-holes have features of 3-dimensional , uniform and funnel shape, which keeps air and water permeable with very low revert. Moreover, the perforation pattern can be versatile and adjustable to meet the market need.

The perforated film unit is a casting film line that specializes in producing a vacuum perforated film. When the resin in the melting state flows down from the extrusion die, a funnel-shaped holes are formed on the film by means of vacuum suction. The vacuum perforated film has a special function because it can filter the liquid and is not easy to flow back. The perforated film produced by this unit is a one-time molding, which saves a lot of energy consumption compared with the traditional two-step perforation method. The whole line is controlled by PLC program and adopts central touch screen operation to realize fully automatic production process. At the same time, we have a variety of hole patterns to choose from, or according to customer-specified hole patterns.

Excellent absorption speed of liquids like water and blood.

The perforation pattern can be customer-made

3-dimensional and uniform holes shape

In-line nonwoven laminating is optional to have perforated composites

Links:https://globefindpro.com/products/2723.html