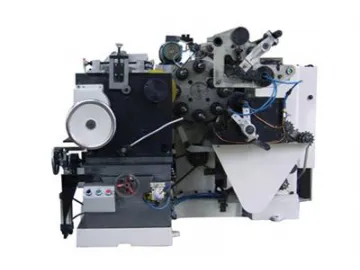

Tube coating machine

Application of equipment and operating principle

The DYD01 primer coating machine is one piece of equipment on an automatic aluminum tube production line, and is primarily used for roller coating on the outer surface of the aluminum tube.

In order to get a better print pattern on the aluminum tube surface and increase the printing aesthetic, a white coating should be applied to the outer tube surface. The tube fell into the "V" type ship through the conveyer, and was inserted into the printing mandrel during the reciprocating movement of the pushing rod. When the central spindle is transferred to the coating station with aluminum tube, the aluminum tube comes into contact with the adhesive roller, and will rotate in the opposite direction of the adhesive roller. At this time, the coating is evenly coated on the tube body through the use of a glue stick to finish the background printing. The bottom coated rotary disc then rotates to the unloading manipulator with an aluminum mandrel, which removes the aluminum tube from the bottom coated mandrel and sends it up the conveyor chain. The aluminum tube enters the bottom coating oven with the conveyor chain. After drying using the primer coating oven, the aluminum tube enters the printing machine.

| suitable tube diameter | φ11mm-φ38mm |

| maximum production rate | 60 tubes/minute |

| motor power | 0.75KW (The main power comes from the printing press) |

| dimension | 2500*1800*1200mm |

| whole machine weight | 1800KG |

Links:https://globefindpro.com/products/27309.html

-

Tube Capping Machine

Tube Capping Machine

-

Impact Extrusion Press for Aluminum Tube Making

Impact Extrusion Press for Aluminum Tube Making

-

Latex Machine

Latex Machine

-

Tube Printing Machine

Tube Printing Machine

-

Latex Coating Machine for Aluminum Tube Sealing

Latex Coating Machine for Aluminum Tube Sealing

-

Annealing Oven

Annealing Oven

-

Internal Lacquering Machine

Internal Lacquering Machine

-

Surface Finishing Trimmer

Surface Finishing Trimmer

-

Drying Oven

Drying Oven

-

Aluminum Tube Trimmer

Aluminum Tube Trimmer

-

Tube coating machine

Tube coating machine

-

Toothpaste Tube Filling and Sealing Machine

Toothpaste Tube Filling and Sealing Machine