Precast Concrete Production Equipment and Molds

The whole PC production line is composed of six parts, including central control system, distributing system, formwork pretreatment system, curing system, formwork circulation system and demoulding system.

1. Central control system 2. Distributing system

(1) Concrete conveying hopper

Conveying hopper is the concrete conveying unit with operating speed of 40m/min, hopper volume between 1.5~3m3, power of 3kW and overall dimension of 2860×2068×1460mm.

(2) Concrete distributing machine

Concrete distributing machine has two optional distributing methods including horizontal and vertical distributing. It is controlled by hydraulic multiple valves to realize the screw extrusion of materials and precise distributing.

(3) Vibration table

The vibration table adopts attached vibration source and the vibration frequency can be adjustable. Vertical vibration and horizontal vibration methods can be adopted.

3.Formwork preprocessing system

(1) Cleaning machine

When components are lifted away, cleaning machine is used to clean the concrete residue on formwork with cleaning width reaching 4m. Its power is 7 kW and overall dimension is 4900×1800×1560mm.

(2) Spraying machine

The spraying machine adopts atomization system to spray demoulding agent to make it attached uniformly on formwork surface. With overall dimension of 4850×1800×1560mm, the spraying machine has spraying width of 4m and total power of 5 kW.

(3) Numerical control marking machine

NC marking machine is used to mark on the formwork surface. Due to the use of servo-control system, the marking is highly precise.

(4) Roughening machine

Roughening machine is used to increase the roughness of the compound slab surface.

(5) Trowelling machine

Trowelling machine is used for the polishing of component surface.

(6) Vibration leveling machine

This machine adopts back and front leveling method and it can be lifted and automatically locked. Meantime, it adopts two-stage vibration damping method, which can effectively solve the vibration problems between vibrating arm and vibrating grid and realize the leveling operation that fully covers the formwork. 4. Curing system

(1) Curing chamber

Two independent sealed curing chambers are equipped with independent temperature control system. Steam heating method is adopted to shorten the curing time.

(2) Stacker

Stacker is used to transport components in and out of curing chamber. It adopts down operating method and has stable structures.

5.Formwork circulation system

(1) Formwork transition carrier

It's used for the horizontal operation of formwork on production line.

(2) Supporting roller

Independently fixed on ground, supporting rollers are load-bearing and conveying wheels of formwork.

(3) Induced collision-prevention device

It belongs to supporting and conveying unit of formwork and is used to avoid collision.

(4) Driving wheel

Driving wheels are made of special rubber that is heat resistant and friction resistant, belonging to conveying unit of formwork.

6.Form removal system (1) Rollover machine

It's used for the overturn of interior and exterior wall panels and components that need to be lifted vertically.

Components and molds Interior wall panels Exterior wall panels Prefabricated balcony slabs Prefabricated staircase Underground utility tunnel Double cell underground utility tunnel Triple cell underground utility tunnel Single-cell box culvert components with waterstops 6 Up-down combined culvert components Single-cell box vertical culvert molds Separated culvert molds Japanese style single horizontal culvert molds

Index

wall panel machine, architectural panel, precast concrete panel

Links:https://globefindpro.com/products/30489.html

-

Single Roller Paint Coating Machine

Single Roller Paint Coating Machine

-

Triple UV Curing Machine

Triple UV Curing Machine

-

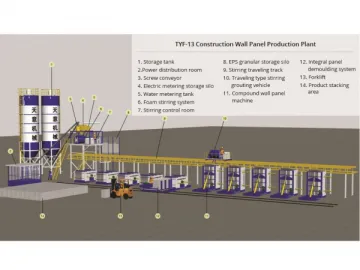

TYF-13 Construction Wall Panel Production Plant

TYF-13 Construction Wall Panel Production Plant

-

Horizontal Belt Conveyor

Horizontal Belt Conveyor

-

Automatic Paint Spraying Machine

Automatic Paint Spraying Machine

-

-

Double UV Curing Machine

Double UV Curing Machine

-

Automatic Loading Conveying Equipment

Automatic Loading Conveying Equipment

-

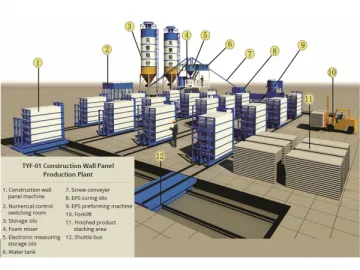

TYF-01 Construction Wall Panel Production Plant (Calcium Silicate Board Compound Wall Panel, Partition Wall)

TYF-01 Construction Wall Panel Production Plant (Calcium Silicate Board Compound Wall Panel, Partition Wall)

-

TY06 Prestressed Wall Panel Machine

TY06 Prestressed Wall Panel Machine

-

Automatic Paint Spraying Line

Automatic Paint Spraying Line

-

TY11 Prestressed Wall Panel Machine

TY11 Prestressed Wall Panel Machine