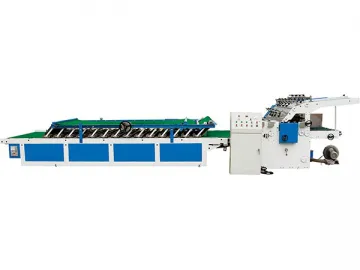

HUAYU-A Series Auto Flexo Printer Slotter Die Cutter & Stacker

HUAYU-A series auto flexo printer slotter die cutter and stacker is mainly used for printing high quality colors on corrugated cartons. It is especially suitable for polychrome printing.

Main Features

1. This type of corrugated box making machine employs advanced belt type lead edge feeder which ensures easy operation, making feeding fast, stable and precise.

2. Our auto flexo printer slotter die cutter and stacker comes with a 7 inch color touch screen which is favorable for order pre-set (200 orders can be pre-set), order inquiry, order memory and readout, synchronous zero set, automatic and manual phase adjustment, parameter management, automatic inking and automatic display of production quantity and speed.

3. All adjustments are available in computer control and motorized control, adapting to user habits and convenient for user selection.

4. The drive rollers of this auto flexo printer slotter die cutter and stacker are all made of high quality steel pipes which have experienced thermal refining, hard chromium plating, correcting and drilling balancing, hence ensuring stable running. Gears are made from high quality alloy steel through quenching treatment.

5. The clearance between rollers can be adjusted depending on the self locking function of worm gear case. Disc handle seat makes it more convenient and faster.

6. Lateral and longitudinal movement of slotting knife are motorized adjust. Box height is also motorized adjust.

7. The die cutting part of this auto flexo printer slotter die cutter and stacker is equipped with speed-limited compensation mechanism so that the die cut roller can move crosswise 40mm.

8. This carton machinery also boasts printing and slotting memory functions, ensuring automatic zero set and automatic slotting reset. The slitter is driven by ball screw, keeping stable operation and high accuracy.

9. Main electrical elements comply with European quality standard.

10. The high speed auto flexo printer slotter, die cutter and stacker, with computer memory function, can memorize 999 orders. The highest speed can reach 150 sheets per minute.

Components of A Series Auto Flexo Printer Slotter Die Cutter & Stacker

Feeder Unit

1. This printing slotting and die cutting machine is provided with a belt type lead edge feeder which features easy operation and maintenance.

2. Thanks to the lead edge device, the paperboard can avoid being warped and feeding error is reduced.

3. Suction hold-down device is typically designed for aiding the feeding of warped board. The suction strength can be manually adjusted as per needs. Display on dial ensures convenience.

4. The left and right side gauge movement can be adjusted by computer. It comes with pneumatic aligning device.

5. Forward and backward back shield movement can also be adjusted by computer. Angle is manually adjusted.

6. The feeder unit of our A series auto flexo printer slotter die cutter and stacker is equipped with a dust removing device to ensure cleaning of the dust and impurity on paperboard, thus improving printing quality.

7. Skip feed function is available. And, continuous feed or skip feed depends on your demand.

8. It is suitable for 3 ply, 5 ply and 7 ply corrugated cardboard, including corrugated board E.

Printer Unit

The flexo printer can implement 1 to 5 color printing or more color printing. It can print not only ordinary cartons but also high quality and high precision polychrome printing cartons such as fruit case, gift box, beer case, etc.

Features of Printer Unit

1. The printer unit of this series flexo printer slotter die cutter and stacker is equipped with steel Anilox roller.

2. It is a standard machine supplied with rubber roller inking system. (Two scraping knife inking system is on option)

3. Quick change device makes mounting and disassembly of flexo printing plates faster and more convenient.

4. Phase adjustment is controlled by PLC and touch screen, which ensures all-round adjustment.

5. Planetary gear phasing adjustment mechanism comes with long service life.

6. The printing unit is provided with an automatic braking device which will prevent the printing cylinder from rotating when it is separated or in phase adjustment. Since that, the original gear position is unchanged.

7. Automatic reset system ensures auto return to zero after the print roll is cleaned.

8. Axial adjustment is controlled by computer with digital display. The adjust distance is up to 20mm.

9. Auto lifting device for the anilox roller makes sure that the anilox roller will rise and be separated with the printing plate when feeding stops.

10. All clearance adjustments can be completed by computer.

Slotter Unit

The slotter unit in this flexo printer slotter, die cutter and stacker is used for making standard corrugated cartons. It can complete slotting, creasing, slitting and corner cutting at one stroke. Slotting size and carton height is motorized or manual adjust.

Features of Slotter Unit

1. The slotting unit comes with double scoring rollers. The paperboard that has been scored in advance is hard to damage.

2. Slotting phase adjustment and carton height adjustment can be done by PLC, with color screen display. It is double frequency adjustment.

3. The phase adjustment device is made of planetary gear, thus ensuring long life span.

4. The slotting head, with width of 7mm, is made from alloy materials by thermal treatment and comes with sharpness and high precision.

5. The clearance of slotting and scoring is controlled by high precision ball screw, PLC and touch screen.

6. The slotter boasts auto zero set function.

7. User-friendly operation interface with color touch screen ensures easy operation.

Die Cutter Unit

The die cutter unit in the flexo printer slotter, die cutter and stacker can be used for die cutting special corrugated boards. 2 to 3 or more boards can be cut at one stroke.

Features of Die Cutter Unit

1. The folding carton die cutter comes with steel die cut roller with hard chrome plating treatment and grinding process on surface.

2. The die cut roller features balance correcting function, hence ensuring stable running.

3. The cushion roller is designed with an automatic moving device on axial direction, allowing it to move about 40mm.

4. An automatic compensation device can prolong the service life of cushion roller.

5. The die cutting phase adjustment is controlled by PLC and color touch screen.

6. Planetary gear structure of phase adjustment device shows long service life.

7. Axial position adjustment is controlled by computer with digital display.

Technical Parameters of A Series Auto Flexo Printer Slotter Die Cutter & Stacker

| NO. | Parameter | unit | Model | |||||

| HYA-295-2300 | HYA-295-2300 | HYA-295-2300 | HYA-295-2300 | HYA-295-2300 | HYA-295-2300 | |||

| 1 | Inner Width | mm | 2300 | 2500 | 2700 | 3100 | 3200 | 4200 |

| 2 | Max. Sheet Size | mm | 920×2000 | 920×2200 | 1300×2400 | 1300×2800 | 1650×3000 | 1650×4000 |

| 3 | Max. Print Area | mm | 850×1800 | 850×2000 | 1250×2200 | 1250×2600 | 1600×2800 | 1600×3800 |

| 4 | Min. Print Area | mm | 280×640 | 280×640 | 350×700 | 350×700 | 420×700 | 420×700 |

| 5 | Max. Machine Speed | Sheet /min | 180 | 140 | 90 | |||

| 6 | Economic speed | Sheet /min | 0-160 | 0-120 | 0-70 | |||

| 7 | Topping precision | mm | ±0.5 | ±0.5 | ±0.5 | |||

| 8 | Standard Print Plate Thickness | mm | 7.2 | 7.2 | 7.2 | |||

| 9 | Cardboard Thickness | mm | 2-11 | 2-11 | 2-11 | |||

| 10 | Min. Slotting Interval | mm | 150×150×150×150 | 165×165×165×165 | 195×195×195×195 | |||

Note:

Machine size can be designed according to the requirements of customer.

Links:https://globefindpro.com/products/43466.html

-

Semi-Auto Carton Folder Gluer

Semi-Auto Carton Folder Gluer

-

HY-A Series Semi-Auto Flexo Printer Slotter

HY-A Series Semi-Auto Flexo Printer Slotter

-

SF-320S(360S) Fingerless Single Facer

SF-320S(360S) Fingerless Single Facer

-

HY-B Series Semi-Auto Flexo Printer Slotter Die Cutter

HY-B Series Semi-Auto Flexo Printer Slotter Die Cutter

-

Thin Blade Slitter Scorer

Thin Blade Slitter Scorer

-

BZJ-B Series Semi-Automatic Flute Laminating Machine

BZJ-B Series Semi-Automatic Flute Laminating Machine

-

SMQ350A Telescopic Crawler Crane

SMQ350A Telescopic Crawler Crane

-

SF-380S(405S) Fingerless Single Facer

SF-380S(405S) Fingerless Single Facer

-

SMQ120A Telescopic Crawler Crane

SMQ120A Telescopic Crawler Crane

-

Pedal Operated Stapler

Pedal Operated Stapler

-

Semi-Auto Stitching Machine

Semi-Auto Stitching Machine

-

HUAYU-C Series Auto Flexo Printer Slotter Die Cutter & Stacker

HUAYU-C Series Auto Flexo Printer Slotter Die Cutter & Stacker