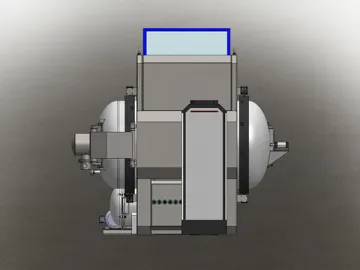

Chemical Vapor Deposition Furnace

The chemical vapor deposition furnace is the specialized industrial furnace for manufacturing high-quality TiC, SiC, SiO2 and Si3N4 applicable for substrates. This experimental electric furnace comes with high deposition temperature ranging 100 to 1800℃.

Our chemical vapor deposition furnace has been proved to be ideal for manufacture of dielectrics, semiconductors and metal films, such as SiO2, Si3N4, amorphous Si:H, heteromorphic Si, SiC, W, Ti-Si, GaAs and GaSb, etc. This high temperature electric furnace is the tool of choice for industries of machinery production, metallurgy, optics and semiconductor.

Structure

1. This chemical vapor deposition furnace mainly comprises vacuum stainless steel hearth, turbomolecular pumping system, power supply, reaction carrier, temperature control system and cooling water assistive device, as well as independent exhaust and reaction pressure adjusting system.

2. The entire structure is compacted. Optimal layout ensures easy operation and fast vacuum pumping.

3. Control system is available as manual control and IPC automatic control.

4. Vacuum pumping and coating can be done in one production cycle.

Technical data| Items | Unit | Model | ||||

| EF-4-18 | EF-8-18 | EF-12-18 | EF-16-18 | EF-20-18 | ||

| Rated power | kW | 21 | 30 | 45 | 60 | 75 |

| Rated voltage | V | 380 | 380 | 380 | 380 | 380 |

| Max. temperature | ℃ | 1800 | 1800 | 1800 | 1800 | 1800 |

| Working temperature | ℃ | ≤ 1700 | ≤ 1700 | ≤ 1700 | ≤ 1700 | ≤ 1700 |

| Vacuum degree | 6.67Pa | 6.67Pa | 6.67Pa | 6.67Pa | 6.67Pa | |

| Substrate platform size | Inch | Ф4 | Ф8 | Ф12 | Ф16 | Ф20 |

| Rotation speed of substrate platform | 0-20RPM | 0-20RPM | 0-20RPM | 0-20RPM | 0-20RPM | |

| Thermal insulation material | Graphite | Graphite | Graphite | Graphite | Graphite | |

| Heating component | Graphite | Graphite | Graphite | Graphite | Graphite | |

| Temperature rising rate | ℃/min | ≤ 25 | ≤ 25 | ≤ 25 | ≤ 25 | ≤ 25 |

| Temperature accuracy | ℃ | ±1 | ±1 | ±1 | ±1 | ±1 |

| Standard configuration | 1. Three-channel flow meter: nitrogen, hydrogen, methane, argon | |||||

| 2. Gas (hydrogen and methane) circuit alarm system, over temperature alarm, water shortage alarm | ||||||

| Options | 1. Exhaust gas handling equipment | |||||

| 2. Gas cylinder and pressure reducing valve | ||||||

| 3. Cooling system | ||||||

Supporting Equipment Microwave Vacuum Sintering Furnace Amorphous Alloy Powder Equipment PSA Nitrogen Generator

Related Names

CVD Equipment | Vapor Deposition Furnace | Chemical Vapor Deposition

Links:https://globefindpro.com/products/43884.html

-

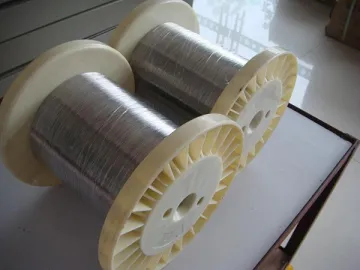

Nickel Chromium Alloy for Electrical Resistance Heating

Nickel Chromium Alloy for Electrical Resistance Heating

-

904L Nickel Alloy

904L Nickel Alloy

-

High Temperature Graphite Furnace

High Temperature Graphite Furnace

-

Vacuum Gas Atomization Powder Manufacturing Equipment

Vacuum Gas Atomization Powder Manufacturing Equipment

-

Incoloy A-286 Nickel Alloy

Incoloy A-286 Nickel Alloy

-

Monel K-500 Nickel Alloy

Monel K-500 Nickel Alloy

-

Water Atomization Powder Manufacturing Equipment

Water Atomization Powder Manufacturing Equipment

-

ERNiCu-7 Nickel Alloy Welding Wire

ERNiCu-7 Nickel Alloy Welding Wire

-

EQNiCr-3 Nickel Alloy Welding Strip

EQNiCr-3 Nickel Alloy Welding Strip

-

Integrated Vacuum Degreasing and Sintering Furnace

Integrated Vacuum Degreasing and Sintering Furnace

-

Inconel 625 Nickel Alloy

Inconel 625 Nickel Alloy

-

Monel 400 Nickel Alloy

Monel 400 Nickel Alloy