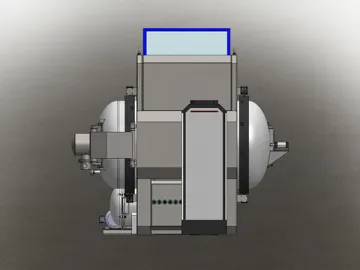

Vacuum Gas Atomization Powder Manufacturing Equipment

EasyFashion vacuum gas atomization powder manufacturing equipment is backed up by constant improvement and innovation through years. Vacuum gas atomization has developed to be the cutting-edge method for high-grade metal and alloy powders. Our powder production machine delivers ultimate purity, fine particle size and no oxidation.

The standard design of our powder manufacturing equipment comprises a vacuum induction melting furnace where alloys are melted, refined and degassed. The melt is poured through the preheated crucible into a gas nozzle, where the melt stream is atomized by high pressure gas.

The metal powder produced solidifies in the atomization tower of this thermal processing equipment and falls into the powder container. The powder gas mixture is transported to the cyclone where gas and fine powder is separated, and then the metal powder is collected in the container located inside the cyclone.

Technical data| Model | EF-10 | EF-25 | EF-50 | EF-100 | EF-200 |

| Feeding capacity (by steel) | 10kg | 25kg | 50kg | 100kg | 200kg |

| Pressure rising rate | 0.133Pa/min | ||||

| Max. vacuum rating | 6 × 10-2Pa | ||||

| Working vacuum rating | 6 × 10-1Pa | ||||

| Input power | 3 phase, 380V, 50Hz | ||||

| Output power | 4000Hz | 2500Hz | 2000Hz | 1000Hz | 1000Hz |

| Medium frequency power supply | 60kW | 100kW | 160kW | 160kW | 250kW |

| Output voltage | 375V | ||||

| Cooling water pressure | 0.2-0.4MPa | ||||

| Input water temperature | 20℃ | ||||

Supporting Equipment Steel Belt Reduction Furnace Sinter-HIP Furnace High Temperature Graphite Furnace

Related Names

Vacuum Atomizing Equipment | Vacuum Atomizer | Vacuum Gas Atomization Equipment | Metal Powder Production Plant

Links:https://globefindpro.com/products/43889.html

-

Incoloy A-286 Nickel Alloy

Incoloy A-286 Nickel Alloy

-

Monel K-500 Nickel Alloy

Monel K-500 Nickel Alloy

-

Vacuum Sintering Furnace

Vacuum Sintering Furnace

-

ERNiCrMo-3 Nickel Alloy Welding Wire

ERNiCrMo-3 Nickel Alloy Welding Wire

-

Kovar 4J29 Nickel Alloy

Kovar 4J29 Nickel Alloy

-

Inconel X-750 Nickel Alloy

Inconel X-750 Nickel Alloy

-

High Temperature Graphite Furnace

High Temperature Graphite Furnace

-

904L Nickel Alloy

904L Nickel Alloy

-

Nickel Chromium Alloy for Electrical Resistance Heating

Nickel Chromium Alloy for Electrical Resistance Heating

-

Chemical Vapor Deposition Furnace

Chemical Vapor Deposition Furnace

-

Water Atomization Powder Manufacturing Equipment

Water Atomization Powder Manufacturing Equipment

-

ERNiCu-7 Nickel Alloy Welding Wire

ERNiCu-7 Nickel Alloy Welding Wire