904L Nickel Alloy

The 904L nickel alloy is a high-alloy austenitic stainless steel with low carbon content. Similar with other frequently used CrNi austenitic steel, the alloy 904L has excellent resistance to pitting and crevice corrosion, stress corrosion cracking and intergranular corrosion. In addition to this, it is also readily to be fabricated and welded.

The low carbon alloy can be used for oil and petrochemical equipment such as reactor, storage and transportation equipment for sulfuric acid, flue gas desulfurization unit in power plant, scrubber and fan in organic acid processing system, etc.

Specifications of 904L Nickel Alloy| UNS | W. Nr |

| N08904 | 1.4539 |

Chemical Compositions

| Composition | Ni | Cr | Mo | Cu | Fe | C | Mn | P | S | |

| Content (%) | Min. | 24 | 19 | 4 | 1 | Bal. | ||||

| Max. | 26 | 21 | 5 | 2 | 0.02 | 2 | 0.03 | 0.015 | ||

Mechanical Properties (Minimum value at 20℃)

| Tensile Strength (σb/MPa) | Yield Strength (σp0.2/MPa) | Elongation (σ5/%) |

| 490 | 215 | 35 |

Product Forms and Standards

| Bar | Forging | Sheet/Strip | Wire | Pipe | Welding wire |

| ASTM B 649 | - | ASTM B 625 | ASTM B 649 | ASTM B6 77 ASTM B 673 | AWS A5.9 ER385 |

Scan QR to Read

Links:https://globefindpro.com/products/43886.html

Links:https://globefindpro.com/products/43886.html

Recommended Products

-

High Temperature Graphite Furnace

High Temperature Graphite Furnace

-

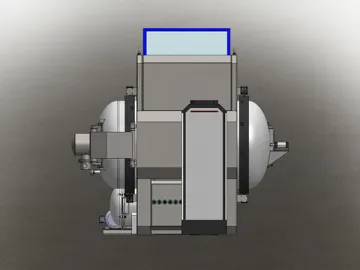

Vacuum Gas Atomization Powder Manufacturing Equipment

Vacuum Gas Atomization Powder Manufacturing Equipment

-

Incoloy A-286 Nickel Alloy

Incoloy A-286 Nickel Alloy

-

Monel K-500 Nickel Alloy

Monel K-500 Nickel Alloy

-

Vacuum Sintering Furnace

Vacuum Sintering Furnace

-

ERNiCrMo-3 Nickel Alloy Welding Wire

ERNiCrMo-3 Nickel Alloy Welding Wire

-

Nickel Chromium Alloy for Electrical Resistance Heating

Nickel Chromium Alloy for Electrical Resistance Heating

-

Chemical Vapor Deposition Furnace

Chemical Vapor Deposition Furnace

-

Water Atomization Powder Manufacturing Equipment

Water Atomization Powder Manufacturing Equipment

-

ERNiCu-7 Nickel Alloy Welding Wire

ERNiCu-7 Nickel Alloy Welding Wire

-

EQNiCr-3 Nickel Alloy Welding Strip

EQNiCr-3 Nickel Alloy Welding Strip

-

Integrated Vacuum Degreasing and Sintering Furnace

Integrated Vacuum Degreasing and Sintering Furnace

Hot Products