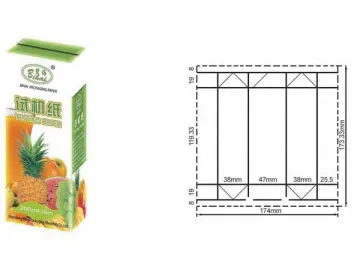

Laminated Liquid Packaging Material

The laminated liquid packaging material is created from multiple layers of paper, aluminum, and plastic. It is airtight, and provides an effective barrier against light. The package is most commonly used to store milk, juice, and beverage. At ambient temperature, it can keep the freshness of the contents for 8 to 12 months. This packaging material is usually employed to make brick cartons at a filling machine.

Types

200ml, 250ml, 125ml, 1000ml

1. PE

2. Bonding Layer

3. Paper

4. PE

5. Bonding Layer

6. Aluminum Foil

7. Bonding Layer

8. PE

9. Modified PE Material

Structure

1. PE: Waterproof, Aseptic, Protective Printed Layer

2. Bonding Layer: To reinforce the binding strength between PE and the paper.

3. Paper: Printed and supportive layer with certain mechanical strength, tenacity, and stiffness.

4. PE: To bind the paper layer. Waterproof, Moisture-tight.

5. Bonding Layer: To reinforce the bind strength between aluminum foil and PE

6. Aluminum Foil: Oxygen barrier, light barrier

7. Bonding Layer: To reinforce the binding strength between aluminum foil and PE.

8. PE: To improve strength and increase thickness

9. Modified PE: Modify teat-sealing performance, ensure sealing tightness

| 100ml base | 125ml slim |

| 200ml slim | 250ml base |

| 250ml slim | 1000ml base |

| 1000ml slim | 1000ml SQ |

As an experienced laminated liquid packaging material manufacturer and supplier in China, we also offer tube type ultra-high-temperature beverage instant sterilizer, U-straw applicator, aseptic filling machine, and more.

Related Names

Brick Shaped Carton Packing Material | Composite Packing Material for Juice Box | Material for Long Time Preservation of Beverage | Protective Packaging Material

Links:https://globefindpro.com/products/45034.html

-

Milk Production Line

Milk Production Line

-

Impact Mill

Impact Mill

-

Buried Scraper Conveyor

Buried Scraper Conveyor

-

Soldering Iron

Soldering Iron

-

Ultra-High-Temperature Sterilizer

Ultra-High-Temperature Sterilizer

-

YIHUA-1501D DC Power Supply

YIHUA-1501D DC Power Supply

-

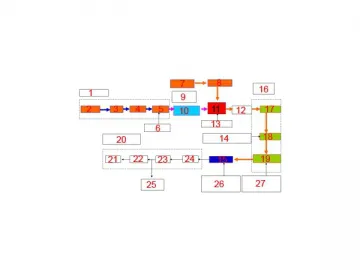

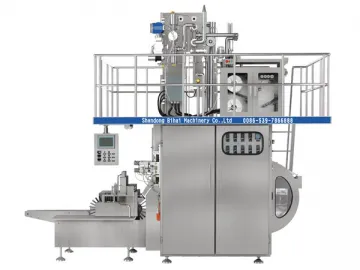

BH2000-1000 Aseptic Carton Filling Machine

BH2000-1000 Aseptic Carton Filling Machine

-

Bucket Elevator

Bucket Elevator

-

YIHUA-853A/946A/946B Series BGA Preheating Station

YIHUA-853A/946A/946B Series BGA Preheating Station

-

60V DC Power Supply

60V DC Power Supply

-

YIHUA-892D SMD Hot Air Rework Station with Soldering Iron

YIHUA-892D SMD Hot Air Rework Station with Soldering Iron

-

BH3000 aseptic carton filling machine

BH3000 aseptic carton filling machine