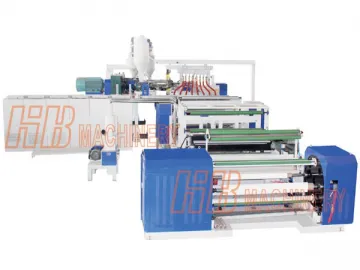

EVA Solar Cell Encapsulation Film Extrusion Line

By adopting the casting technology, our EVA solar cell encapsulation film extrusion line is developed for producing the EVA solar cell encapsulation film. The main raw material is the EVA (ethylene-vinyl acetate) resin that contains 30%-33% VA (vinyl acetate). It also enables the production of EVA hot melt adhesive film for laminated glasses once changing the formula and the production technique.

Features of Our Production Line

1. The professionally designed stress relieving device can promptly and effectively eliminate the residual stress caused by film stretching or caused during the production. Therefore, the heat shrinkage problem of EVA adhesive films is well solved.

2. The EVA solar cell encapsulation film extrusion line is equipped with unique low-temperature extrusion system which can guarantee good material mixing and plasticizing effects. In the meantime, this system also avoids the advance curing and cross-linking of additives.

3. The specially-designed forming unit perfectly solves the problems as sticking roller and film stripping.

4. It can be manufactured according to the specific requirements of customers.

Characteristics of EVA Adhesive Film

This film comes with the thickness of 0.30-0.80mm and the strengths as environmental protection, long-lasting resistance to UV, non-yellowing, high transparency, strong cohesiveness, ageing resistance, low hot-shrinkage rate, etc.

Main Applications of Films Produced by Our Production Line

1. EVA solar cell adhesive film

This film produced by our EVA solar cell encapsulation film extrusion line is used for solar cell encapsulation. Under normal temperature, it is not adhesive and the operation is very simple. Once hot pressed, it will behave with thermal-crosslinking, curing and adhesion enhancement reactions, thus the permanent adhesive sealing is achieved.

2. EVA adhesive film for laminated glasses

It is a kind of thermosetting adhesive film applicable to the laminated glass. The laminated glass made with this film completely conforms to the national standard GB9962-99 (Safety Glazing Materials in Building).

Parameters of Our Production Line

| Model (mm) SJLM-EVA-Z | 1620 | 2000 |

| Screw Diameter (mm) | 110 | 125 |

| Width of Die (mm) | 1800 | 2250 |

| Width of Finished Film (mm) | 1620 (810×2 rolls) | 2000 (1000×2 rolls) |

| Thickness of Finished Film (mm) | 0.3-0.8 | 0.3-0.8 |

| Maximum Extrusion Capacity (kg/h) | 200 | 400 |

| Linear Speed of Machine (m/minute) | 10 | 10 |

| Total Installed Power (KW) | 180 | 240 |

| Overall Dimensions (L×W×H) (m) | 30×7×3.5 | 31×8×3.5 |

| Weight (T) | 25 | 35 |

Note: The above data are subject to change without prior notice.

Links:https://globefindpro.com/products/45289.html

-

Laminated Glass TPU Film Extrusion Line/High Transparency TPU Sheet (Shoe Material ) Extrusion Line

Laminated Glass TPU Film Extrusion Line/High Transparency TPU Sheet (Shoe Material ) Extrusion Line

-

Automatic Stretch Film Rewinder

Automatic Stretch Film Rewinder

-

TPU (PEVA/PE) Film and Coating Lamination Line

TPU (PEVA/PE) Film and Coating Lamination Line

-

Vertical Slag Mill

Vertical Slag Mill

-

Single Stage Hammer Crusher

Single Stage Hammer Crusher

-

3D PP Film and Sheet Extrusion Line

3D PP Film and Sheet Extrusion Line

-

Impact Hammer Crusher

Impact Hammer Crusher

-

Single-side/Double-side High Speed Paper Film Coating Lamination Line

Single-side/Double-side High Speed Paper Film Coating Lamination Line

-

Lime Rotary Kiln

Lime Rotary Kiln

-

Double-layer/Three-layer Co-extruded Film Lamination Line

Double-layer/Three-layer Co-extruded Film Lamination Line

-

1800-2100mm PVC Cling Film Extrusion Line with Three Shaft Winder

1800-2100mm PVC Cling Film Extrusion Line with Three Shaft Winder

-

1200-1800mm PVC Cling Film Extrusion Line with Double Shaft Winder

1200-1800mm PVC Cling Film Extrusion Line with Double Shaft Winder