Tube Grinding Mill

Our tube grinding mill is applicable for grinding various materials like ores. It is commonly found in industries like building material, metallurgy, chemical, power generation, and more. It fits both dry and wet type grinding.

Although designed for open circuit grinding, the grinding machine can also be used for circulatory closed-circuit grinding when used in combination with a powder classifier. It supports synchronous grinding and drying operations.

The tube grinding mill supports easy adjustment on grinding fineness, and has features like strong material adaptability, powerful continuous production capacity, and large size reduction ratio.

Technical Parameters| Specification (diameter×length) (m) | Rotation speed (r/min) | Feeding size (mm) | Productivity (t/h) | Material loading capacity (t) | Main motor | Main speed reducer | Weight (t) | |||

| Model | Power (kw) | Rotation speed (r.p.m) | Model | Speed ratio | ||||||

| 2.2×11 | 20.91 | ≤25 | 15~17 | 50 | TR1512-8 | 570 | 740 | Zd80 | 5.6 | 92 |

| 2.4×8 | 20.91 | ≤25 | 14~18 | 39.5~42 | TRQ1512-8 | 570 | 740 | Zd80-9 | 5 | 76.4 |

| 2.4×9 | 20.91 | ≤25 | 23~25 | 50 | TR1512-8 | 570 | 740 | Zd80-9 | 5 | 91 |

| 2.4×10 | 20.91 | ≤25 | 16~22 | 50 | TR1512-8 | 570 | 740 | Zd80-9 | 5 | 111 |

| 2.4×11 | 21 | ≤25 | 19~2422~28 | 6265 | YR710-8/1180 | 710 | 740 | JDX630 | 5.6 | 125 |

| 2.4×12 | 21 | ≤25 | 18~2021~23 | 6365 | YR800-8/1180 | 800 | 740 | MBY710 | 6.3 | 127 |

| 2.4×13 | 21 | ≤25 | 21~2224~26 | 6668 | YR800-8/1180 | 800 | 740 | MBY710 | 6.3 | 131 |

| 2.6×10 | 20.6 | ≤25 | 21~24 | 64 | YR800-8/1180 | 800 | 740 | JDX710 | 6.3 | 140 |

| 2.6×13 | 20.6 | ≤25 | 28~31 | 81 | YR1000-8/1180 | 1000 | 740 | JDX800 | 6.3 | 158 |

| 3.0×9 | 19.13 | ≤25 | 40~45 | 85 | YR1000-8/1180 | 1000 | 740 | MBY800 | 7.1 | 148 |

| 3×11 | 18.92 | ≤25 | 44~47 | 95 | YR1250-8/1430 | 1250 | 740 | JDX900 | 7.1 | 177 |

| 3×12 | 18.92 | ≤25 | 48~52 | 103 | YR1250-8/1430 | 1250 | 740 | JDX900 | 7.1 | 182 |

| 3×13 | 18.92 | ≤25 | 39~45 | max.116 | YR1400-8/1430 | 1400 | 740 | JDX900 | 7.1 | 200.7 |

| 3.2×11 | 18.3 | ≤25 | 45~48 | max.112 | YR1600-8/1430 | 1400 | 740 | JDX900 | 7.15 | 213.6 |

| 3.2×13 | 18.7 | ≤25 | 50~55 | max.133 | YR1600-8/1430 | 1600 | 740 | JDX1000 | 7.15 | 237 |

| 3.4×11 | 18 | ≤25 | 45~55 | max.120 | YR1600-8/1430 | 1600 | 740 | JDX1000 | 230 | |

| 3.5×13 | 17 | ≤25 | 60~65 | max.156 | YR2000-8/1730 | 2000 | 740 | TS130-A-F1 | 257.6 | |

| 3.8×13(main bearing type) | 17 | ≤25 | 65~70 | 190 | YR2500-8/1730 | 2500 | 740 | JS130-C-F1 | 316 | |

| 3.8×13 | 17 | ≤25 | 65~70 | 185 | YR2500-8/1730 | 2500 | 740 | DMG22/2500 | 313 | |

| 4×13 | 16.3 | ≤25 | 78~80 | 191 | YRKK900-80 | 2800 | 745 | JS140-A | 348 | |

| 4.2×11(main bearing type) | 15.8 | ≤25 | 100~110 | 182~190 | YR2800-8/17830 | 2800 | 740 | JS140-A-F1D | 350 | |

| 4.2×13(main bearing type) | 15.2 | ≤25 | 120~130 | 245 | YRKK1000-8 | 3350 | 740 | MFY355-A | 390 | |

| 4.2×13 | 15.2 | ≤25 | 110~120 | 230 | YRKK1000-8 | 3350 | 740 | MFY355-A | 380 | |

| 4.6×14 | 15 | ≤25 | 100~115 | 285 | YR1000-8 | 4200 | 740 | J3160-C | 485 | |

Note: Above parameters are provided for your reference only. Specific ones will be provided in purchasing contracts.

Related Names

Cement Grinding Machine | Ultrafine Pulverizer | Cement Roller Mill

Links:https://globefindpro.com/products/45336.html

-

Hammer Crusher

Hammer Crusher

-

1.2 Million Ton Cement Grinding Machine

1.2 Million Ton Cement Grinding Machine

-

2 Million Ton Cement Grinding Station

2 Million Ton Cement Grinding Station

-

Slag Grinding Mill

Slag Grinding Mill

-

Monocular Cooler

Monocular Cooler

-

Rubber Belt Conveyor

Rubber Belt Conveyor

-

Automatic Liquid Resistance Starter

Automatic Liquid Resistance Starter

-

Cement Production Line Distributed Control System

Cement Production Line Distributed Control System

-

Vertical Coal Mill

Vertical Coal Mill

-

Vibrating Feeder

Vibrating Feeder

-

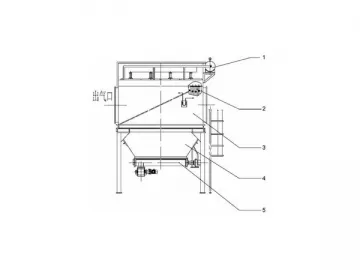

Air Tank Pulse Bag Filter

Air Tank Pulse Bag Filter

-

Cyclonic Dust Collector

Cyclonic Dust Collector