Tetrahedron Package Snack Food Packaging Machine

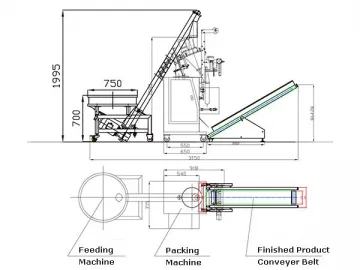

This series of snack food packaging machine features a material loading system that requires some manual handling tasks. For products that do not require precise weight measurement, operators can count the quantity of the materials or measure their volume before placing them into the hopper. For applications where precise measurement is called for, users should prepare an electronic platform scale for precisely measuring the materials and then pouring them into the hopper.

The material loading system is equipped with a self-dumping hopper, which can automatically dump the material into the bag. During this dumping process, materials with bad flowability tend to stick to the coarse hopper surface, resulting in blocking of the passage. If that is the case, we will apply a layer of Teflon to the material contact surface. Teflon coating reduces the ability of material to stick to it.

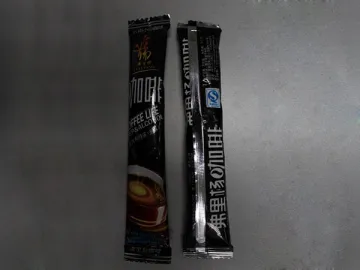

The package made by this packaging machine comes in tetrahedron shapes. It can be filled with nitrogen to retard the growth of bacteria that might spoil the product. In addition to extending the shelf life of the product, inflating with inert gas also reduces the crushing of products like potato chips during transportation. The gas makes the bag look bulgy, creating an attractive appearance.

All the parts of the machine that might be in contact with the material are made of stainless steel, including the packer case. The machine is certified to CE standard.

Parameters

| Specifications Model Number | DCFDS-300 |

| Maximum Plastic Film Width | 300mm |

| Measuring Tool | Self-Dumping Hopper |

| Range of Volume | 0-350ml |

| Bag Width | 30-140mm |

| Bag Length | 30-170mm |

| Sealing Type | Tetrahedron Packaging |

| Packaging Speed | 20-60packs/minute |

| Power Supply | 220V, 1.6KW |

| Dimension (L×W×H) | 950×1300×1700mm |

| Weight | 250kg |

Related Names

Sachet Filling Machine | Plastic Food Packing Equipment | Plastic Pouch Packaging Machine

Links:https://globefindpro.com/products/45830.html

-

BELIMO-Automatic Air Vent

BELIMO-Automatic Air Vent

-

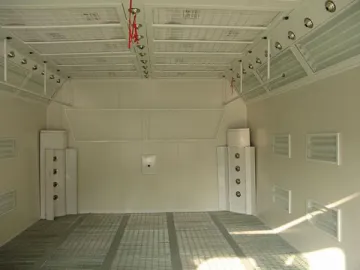

BZB-T8000EU Car Spray Booth (European Standard)

BZB-T8000EU Car Spray Booth (European Standard)

-

Water-borne Painting System

Water-borne Painting System

-

6500 Prep Station

6500 Prep Station

-

Sweets Packing Machine

Sweets Packing Machine

-

DCCK-300 Weighing Packing System

DCCK-300 Weighing Packing System

-

Biscuit Packing Machine

Biscuit Packing Machine

-

Tea Bag Filling and Sealing Machine

Tea Bag Filling and Sealing Machine

-

Centrifugal Fan

Centrifugal Fan

-

Hair Conditioner Packing Machine

Hair Conditioner Packing Machine

-

DCCK-400/500/600 Weighing Packing System

DCCK-400/500/600 Weighing Packing System

-

Coffee Packaging Machine

Coffee Packaging Machine