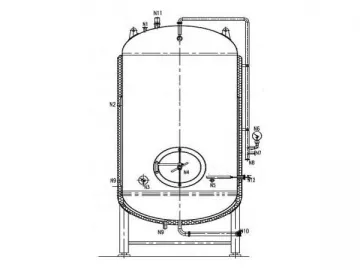

Steam Heated Mixing Tank

This steam heated mixing tank is made completely from stainless steel. All parts in touch with feed materials are formed by stainless steel 304 or stainless steel 316L, which cover the requirements with respect to sanitation. Our product has already achieved CE certification, and it is made in accordance with ISO standards. Its production capacity ranges from 100L to 25,000L.

Our product can be widely used in coatings, pharmaceuticals, building materials, chemicals, pigments, resins, food, and scientific research, among other industries. Its main function is to stir or homogenize various materials.

1. Optional Jackets

This steam heated mixing tank is designed with various jackets for option, compromising the dimple jacket, coiled-tube jacket, and the overall jacket.

2. Great Thermal Insulation

Its insulating layer makes use of PU foam, thus providing wonderful thermal-insulation effect.

3. Polishing Technology

This container is internally subjected to a mirror polishing process, and its roughness average is no more than 0.4. In addition, the treatment methods for the outer surface of our container are selectable, such as a brushed finish, satin finish, and 2B finish. We can also accord with customer requirements to design and make our steam heated mixing tank.

4. Heating Method

The material is heated by steam. Our clients are required to tell us the steam pressure inside the jacket, so as to select an appropriate thickness of stainless steel sheets.

5. Mixing Type

The available types of stirrers are the propeller type, paddle type, frame type, anchor type, magnetic type, high-shear emulsification type, ribbon type, turbo type, and the hinge type, among others.

6. Installation Methods and Brands of The Mixer Motor

The brands of our mixer motor are optional, including ABB, SEW, Siemens, and the ordinary domestic motors. The installation methods of the mixer motor are also selectable, such as top mounting, side mounting, and bottom mounting.

7. Agitation Rate

During the stirring process, the rotational speed can be either fixed or regulated by mounting a frequency converter. If required, a control cabinet can be adopted to control the agitation rate.

8. Fittings

Our steam heated mixing tank is equipped with such fittings as the quick-opening manhole, sight glass, cleaning ball, thermometer, pressure gauge, the material-outlet matching butterfly valve, the electronic weighing system, as well as the liquid level gauge and liquid level control system. The last two fittings can be mounted as per customer requirements.

Related Names

Chemical Container | Agitation Tank | Liquid Mixing Equipment

Links:https://globefindpro.com/products/45919.html

-

Milk Bucket

Milk Bucket

-

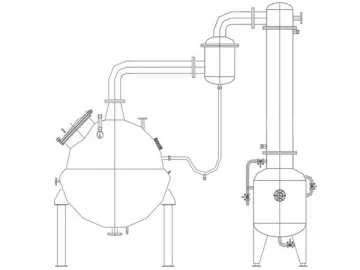

Ball Shaped Concentration Tank

Ball Shaped Concentration Tank

-

High Shear Mixing Tank

High Shear Mixing Tank

-

Brite Tank

Brite Tank

-

Vacuum Pressure Relief Concentration Tank

Vacuum Pressure Relief Concentration Tank

-

Stainless Steel 135 Degree Elbow

Stainless Steel 135 Degree Elbow

-

Plate UHT Pasteurizer

Plate UHT Pasteurizer

-

Electrical Heating Jacketed Kettle

Electrical Heating Jacketed Kettle

-

Falling Film Evaporator

Falling Film Evaporator

-

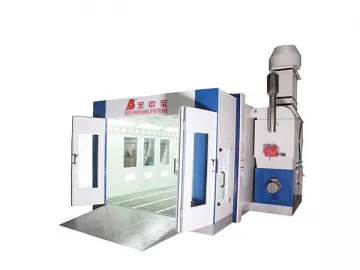

BZB-8700 Car Spray Booth

BZB-8700 Car Spray Booth

-

700A Prep Station

700A Prep Station

-

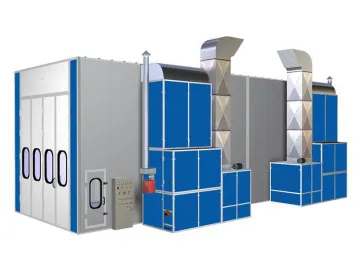

BZB-FB-1500H 15m Bus Spray Booth

BZB-FB-1500H 15m Bus Spray Booth