Plate UHT Pasteurizer

Our plate UHT pasteurizer takes advantage of the heat transfer principle and the law of thermodynamics. Heat is spontaneously transferred from a hot object to a cold one. Heat transfer must occur as the temperature difference exists in two fluids.

The surface of the heat transfer plate of our plate UHT pasteurizer adopts the optimized design of corrugated structure, and the heat transfer rate reaches up to 92%. The fluid between two plates continues making three-dimensional movement, even though the flow velocity is lower than Renault permitted value. This allows the liquid to form turbulent flow, which can not only reduce the heat resistance of the verges of plates, but also enhance the heat transfer efficiency.

Pasteurized Milk

Process: 5℃ →65℃ (homogeneous) →120℃ (30s) →5℃

(Ice water temperature) 2℃

| Model | Capacity (T/h) | Steam Consumption (kg/h) | Steam Pressure (kg) | Ice water Flow (T/h) | Power (kW) | Dimension (L)*(W)*(H)m | Weight (kg) | Diameter(mm) | ||

| Product | Steam | Medium | ||||||||

| BR0.1C-X-1MJ | 1 | 20 | 2.5 | 3000 | 1.9 | 1.6x1.4x1.8 | 560 | 25 | 1" | 25 |

| BR0.1C-X-1.5MJ | 1.5 | 30 | 2.5 | 4500 | 2.2 | 1.6x1.4x1.8 | 560 | 25 | 1" | 25 |

| BR0.25C-X-2MJ | 2 | 94 | 2.5 | 6000 | 4 | 2.0x1.8x2.0 | 560 | 38 | 1" | 38 |

| BR0.25C-X-3MJ | 3 | 141 | 2.5 | 9000 | 4 | 2.0x1.8x2.0 | 630 | 38 | 1" | 38 |

| BR0.25C-X-4MJ | 4 | 188 | 2.5 | 12000 | 4 | 2.0x1.8x2.0 | 710 | 38 | 1" | 38 |

| BR0.25C-X-5MJ | 5 | 235 | 2.5 | 15000 | 5.5 | 2.3x1.8x2.0 | 760 | 51 | DN32 | 51 |

| BR0.25C-X-6MJ | 6 | 282 | 2.5 | 18000 | 5.5 | 2.3x1.8x2.0 | 850 | 51 | DN32 | 51 |

| BR0.25C-X-8MJ | 8 | 376 | 2.5 | 24000 | 5.5 | 2.3x1.8x2.0 | 980 | 51 | DN32 | 51 |

| BR0.6C-X-10MJ | 10 | 470 | 2.5 | 30000 | 7.8 | 2.5x1.8x2.0 | 1590 | 51 | DN32 | 51 |

| BR0.6C-X-15MJ | 15 | 650 | 2.5 | 45000 | 11.0 | 2.5x1.8x2.0 | 1700 | 63 | DN40 | 63 |

Pasteurized Milk, Yogurt Double-Duty

Process: 5℃ →65℃ (homogeneous) →120℃ (30s) →5℃

(Ice water temperature) 2℃ ↘95℃ (300s) →43℃

| Model | Capacity (T/h) | Steam Consumption (kg/h) | Steam Pressure (kg) | Ice water Flow (T/h) | Power (kW) | Dimension (L)*(W)*(H)m | Weight (kg) | Diameter (mm) | ||

| Product | Steam | Medium | ||||||||

| BR0.1C-XS-1MJ | 1 | 40/76 | 4.0 | 3000 | 3.0 | 1.6x1.4x1.8 | 560 | 25 | 1" | 25 |

| BR0.25C-XS- 2MJ | 2 | 94/152 | 4.0 | 6000 | 4 | 2.0x1.8x2.0 | 600 | 38 | 1" | 38 |

| BR0.25C-XS-3MJ | 3 | 141/228 | 4.0 | 9000 | 4 | 2.0x1.8x2.0 | 680 | 38 | 1" | 38 |

| BR0.25C-XS-4MJ | 4 | 188/304 | 4.0 | 12000 | 4 | 2.0x1.8x2.0 | 760 | 38 | DN25 | 38 |

| BR0.25C-X-5MJ | 5 | 235/380 | 4.0 | 15000 | 5.5 | 2.3x1.8x2.0 | 850 | 51 | DN32 | 51 |

| BR0.25C-X-6MJ | 6 | 282/456 | 4.0 | 18000 | 5.5 | 2.3x1.8x2.0 | 920 | 51 | DN32 | 51 |

Untreated Juice

Process: 35℃ →98℃ →105℃ (30s) →53℃

| Model | Capacity (T/h) | Steam Consumption (kg/h) | Steam Pressure (kg) | Power (kW) | Dimension (L)*(W)*(H)m | Weight (kg) | Diameter (mm) | ||

| Product | Steam | Medium | |||||||

| BR0.25C-GZ-5MJ | 5 | 430 | 4.0 | 3.7 | 2.0x1.6x2.0 | 1120 | 38 | DN50 | 38 |

| BR0.25C-GZ-10MJ | 10 | 860 | 4.0 | 3.7 | 2.0x1.6x2.0 | 1320 | 51 | DN65 | 51 |

| BR0.4C-GZ-15MJ | 15 | 1290 | 4.0 | 7.0 | 2.5x2.5x2.2 | 2020 | 63 | DN80 | 63 |

| BR0.4C-GZ-20MJ | 20 | 1720 | 4.0 | 8.0 | 2.5x2.5x2.2 | 2220 | 63 | DN80 | 63 |

| BR0.6C-GZ-25MJ | 25 | 2150 | 4.0 | 11.0 | 2.5x2.5x2.2 | 2520 | 76 | DN100 | 76 |

| BR0.6C-GZ-30MJ | 30 | 2580 | 4.0 | 11.0 | 2.5x2.5x2.2 | 2720 | 76 | DN100 | 76 |

| BR0.6C-GZ-40MJ | 40 | 3440 | 4.0 | 11.0 | 2.5x2.5x2.5 | 3120 | 101 | DN125 | 101 |

| BR0.6C-GZ50MJ | 50 | 4300 | 4.0 | 11.0 | 2.5x2.5x2.5 | 3500 | 101 | DN125 | 101 |

Related Names

Milk Pasteurization Equipment | Dairy Pasteurizer | Cream Sterilizing Machine

Links:https://globefindpro.com/products/45918.html

-

Steam Heated Mixing Tank

Steam Heated Mixing Tank

-

Milk Bucket

Milk Bucket

-

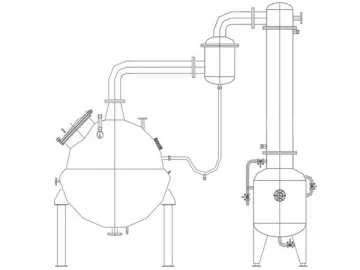

Ball Shaped Concentration Tank

Ball Shaped Concentration Tank

-

High Shear Mixing Tank

High Shear Mixing Tank

-

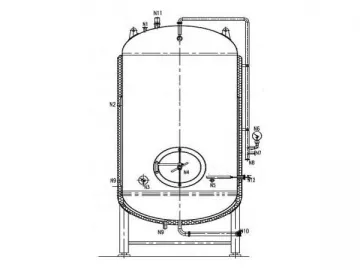

Brite Tank

Brite Tank

-

Vacuum Pressure Relief Concentration Tank

Vacuum Pressure Relief Concentration Tank

-

Electrical Heating Jacketed Kettle

Electrical Heating Jacketed Kettle

-

Falling Film Evaporator

Falling Film Evaporator

-

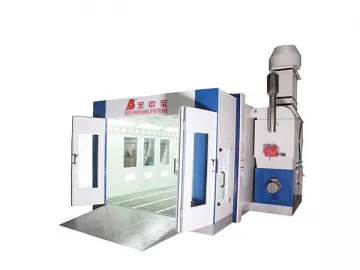

BZB-8700 Car Spray Booth

BZB-8700 Car Spray Booth

-

700A Prep Station

700A Prep Station

-

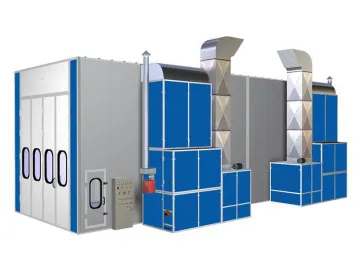

BZB-FB-1500H 15m Bus Spray Booth

BZB-FB-1500H 15m Bus Spray Booth

-

Chain Conveyor Shot Blasting Machine

Chain Conveyor Shot Blasting Machine