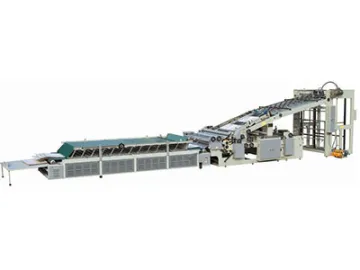

Automatic Flute Laminating Machine

MKL series automatic flute laminating machine is the fourth-generation product with advantages of easy operation, convenient maintenance, high speed, low noise and high accuracy. With automatic cardboard feeder and automatic flute feeder, it realizes complete automation. Because of excellent performances, our product is suitable for laminating color printing paper and A, B, C, D and E flute corrugated cardboard. What's more, it will provide customers with more excellent equipments, which help you to gain the competitive power in the market.

| Model | MKL-1300 | MKL-1450 | MKL-1600 |

| Maxi Laminating Size | 1300x1100mm | 1450x1100mm | 1600x1400mm |

| Mini Laminating Size | 350x350mm | 350x350mm | 450x450mm |

| Laminating Precision | ≤±1.5mm | ≤±1.5mm | ≤±1.5mm |

| Speed | 100s/min | 100s/min | 100s/min |

| Length | 12500mm | 12500mm | 15000mm |

| Total Power | 12kw | 12kw | 13kw |

| Weight | 6800kg | 7200kg | 8000kg |

Features

By adopting automatic vacuum cups feeder system, our automatic flute laminating machine guarantees smooth and precise high speed sheet sending with no wearing, thus improving efficiency. On the other hand, suction head movement of linear slippery guide system can ensure stable bottom sheet sending.

With elastic front register positioning, the bottom sheet does not exceed the top one and the front-and-back distance between the top sheet and the bottom sheet can be adjusted.

Integrated control with PLC and touch screen display can provide easy operation and automatic fault alarm. Also, circuitry can run in stability and credibility.

An automatic glue supply system ensures that a full measure of glue is always available for gluing for optimum control and a minimum of consumption. Recycling glue supply system enables to make full use of glue.

With the scientific design of roll line measurement, it not only ensures uniform glue, but also avoids glue rejection when our flute laminating machine operates at a high speed.

By using roller wash, no glue residue will be left on the bottom roller or on the back of corrugated paper. Thus it keeps you off the trouble of frequently changing scrapers. Also, water cycle controlled by independent water cycle ensures cleanness and no glue residue.

Movable press machine which is floatable provides firm and even pressure, ensuring the laminated corrugated cardboard in good condition. In addition, the couching roll works smoothly by using worm-and-gear unilateral adjustment method to adjust pressure.

MAY KWA is an experienced automatic flute laminating machine manufacturer in China. Our company also offers hand platen die cutting creasing machine, water based OPP film laminating machine, auto spot UV coating machine and more.

Related Products

Cardboard Manufacturing Machines | China Paper Machine Company | Paper Corrugation Machine

Links:https://globefindpro.com/products/46625.html