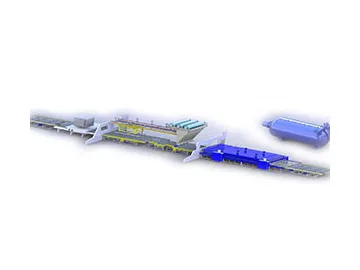

Glass Cross Cutting Machine (including length measuring, signal generator and glass edge severing)

Advantages

1. Our glass cross cutting machine provides human-machine interface, and functions of optimized cutting and jump cutting (when cutting thin glass with small length, after the first cutter cuts the glass, the second cutter carries out the second cutting). According to the positions of flaws on the glass plate, it can optimize cutting by automatically choosing from the predetermined sizes (including three specification options for glass product and one for waste product).

2. The glass cutter also has the function of double-cutter alternate cutting (which is used under circumstances that the glass plate is moving too fast and undergoes small-size cutting).

3. There are two cutters, with one cutter acting as a backup for the other; when there is something wrong with the cutter that is working or in case of changing the cutter, the other will start automatically cutting the same size.

4. The glass cross cutting machine has order storage capability.

5. It can set the positions for cutter lifting and lowering by means of the signals it receives from a glass longitudinal cutting machine.

6. In addition to sending signals on glass breaking, the glass cutting machine can provide not only synchronous lowering but also individual control of the tool carrier, pressing wheel and cutter wheel.

Use

The glass cross cutting machine is used for cutting glass ribbon transversely.

Technical Parameters

| Max. cutting width | 5M |

| Thickness | 1mm~19mm |

| Cutting tolerance for glass height | ±0.5mm |

| Cutting tolerance for diagonal line | ±1mm |

| Pressure adjustment | 0~100N |

| Max. running speed | 3m/s |

| Suitable glass ribbon speed | 50m~1200m/h |

| Range of cutting length | 0.6-10m |

Yuntong is a professional glass cross cutting machine manufacturer in China. We provide a variety of products including glass conveying roller, dual-chamber convection heating flat glass tempering furnace, dross box, top cover, horizontal glass washing machine, and others.

Terms of trade

1. Minimum order quantity (MOQ): one piece or complete plant

2. Delivery time: 3-6 months (except float glass production line)

3. Port of loading: port of Tianjin (Xingang)

4. Terms of payment: advance payment (30% TT) + payment before shipment (60% LC or TT) + the balance of payment (10% TT or LC) after final acceptance.

Links:https://globefindpro.com/products/47843.html

-

Rubber Cosmetic Cap 1489

Rubber Cosmetic Cap 1489

-

Vertical Glass Washing Machine

Vertical Glass Washing Machine

-

PP Cosmetic Cap 533

PP Cosmetic Cap 533

-

Laminated Glass Production Line

Laminated Glass Production Line

-

Cold End Equipment for Float Glass Production Line

Cold End Equipment for Float Glass Production Line

-

Roller for Annealing Lehr

Roller for Annealing Lehr

-

ABS Cosmetic Cap 729

ABS Cosmetic Cap 729

-

Semi-automatic Glass Laminating Line

Semi-automatic Glass Laminating Line

-

50ml Glass Perfume Bottle 2518H

50ml Glass Perfume Bottle 2518H

-

50ml Glass Perfume Bottle T719

50ml Glass Perfume Bottle T719

-

50ml Glass Perfume Bottle 3094H

50ml Glass Perfume Bottle 3094H

-

50ml Glass Perfume Bottle 2748T

50ml Glass Perfume Bottle 2748T