Knurl Machine

Advantages

There are many types of knurl machines such as suspending type, stand type, semi-automatic, full-automatic, and more. Fitted on both sides of a tin bath, knurl machines play an important role in improving glass quality, glass production rate, and thick or thin glass making.

Parameters of each knurl machine can be adjusted in the central control room. The machine offers automatic, safe and reliable operation.

Use

The knurl machine is used for glass thinning and thickening, ensuring stable running of glass.

Suspending Knurl Machine

| Linear speed | 50~1000m/h |

| Horizontal swing angle range | ±20° |

| Travel route of machine head | 3000mm |

| Head radial run out less than | 0.2mm |

| machine rod horizontal lifting | 80mm |

| Glass thickness | 2~19mm |

| Pressing depth range | 100mm |

| Machine head diameter | ∮214, double rows of teeth |

Water supply: Water conforms to industrial soft water standard, water pressure is 0.3MPA, and water flow is 10M 3/h per couple

Stand Knurl Machine

| Glass thickness | 3~19mm |

| Tolerance of radial runout for main shaft | 0.2mm |

| Travel route of machine rod | 1500mm. |

| Effective length of machine rod | 3000mm |

| Stretching accuracy | ±1mm |

| Pressing depth range | 80mm |

| Press-position accuracy | ±0.1mm |

| Swing angle range | ±20° |

| Swing angle adjusting accuracy | ±0.1° |

| Emergency lifting time | 3s |

| Machine head lifting & dropping route | 100mm Accuracy ±3mm |

| Machine head size | Ф214mm, double rows of teeth |

| Machine linear speed | 50~1000m/h, corresponding linear accuracy 1/1000 |

Water conforms to industrial soft water standard, water pressure is 0.15MPa, and water flow is 5m3/h for each set.

Yuntong is a professional knurl machine manufacturer in China. We offer various types of products such as forced convection heating flat glass tempering furnace, glass longitudinal cutting machine, glass stacker, laminated glass processing equipment, and glass washing machine.

Terms of trade

1. Minimum order quantity (MOQ): one piece or complete plant

2. Delivery time: 3-6 months (except float glass production line)

3. Port of loading: port of Tianjin (Xingang)

4. Terms of payment: advance payment (30% TT) + payment before shipment (60% LC or TT) + the balance of payment (10% TT or LC) after final acceptance.

Links:https://globefindpro.com/products/47857.html

-

Longitudinal Snapping and Separation Device

Longitudinal Snapping and Separation Device

-

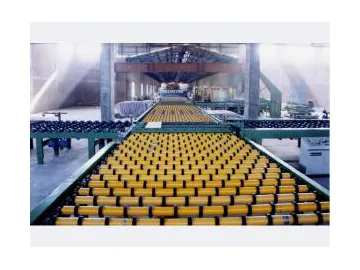

Glass Conveying Roller

Glass Conveying Roller

-

35ml Glass Perfume Bottle 2510T

35ml Glass Perfume Bottle 2510T

-

Gas Heating Glass Tempering Furnace

Gas Heating Glass Tempering Furnace

-

32ml Glass Perfume Bottle 2969T

32ml Glass Perfume Bottle 2969T

-

ABS Cosmetic Cap 585

ABS Cosmetic Cap 585

-

Glass Distribution Machine

Glass Distribution Machine

-

Horizontal Glass Washing Machine

Horizontal Glass Washing Machine

-

Horizontal Glass Washing and Drying Machine

Horizontal Glass Washing and Drying Machine

-

30ml Glass Perfume Bottle T558

30ml Glass Perfume Bottle T558

-

Full Set of Annealing Lehr Equipment

Full Set of Annealing Lehr Equipment

-

Cross Snapping Device

Cross Snapping Device