Extrusion Press (for Φ95mm Rod)

Copper Rod Extruder, Brass Extrusion Machine, Copper Rod Extrusion Press

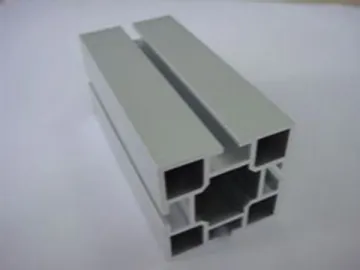

As being an indirect extrusion machine, this copper rod extruder has some features different from direct extrusion press. For example, the ram forces the billet to move forward and pass through the die opening in direct extrusion. However, in indirect extruder, the die is mounted to a hollow ram and finished products will come out from the inner bore of the ram.

Major Features of Copper Rod Extrusion Press

1. Because of no relative movement between container and billet, there will be no friction or heat during the machine operation.

2. To complete the same extrusion work, 25%-30% extrusion force will be decreased in comparison to the direct extruder.

3. The brass extrusion machine is capable to process profiles with a smaller cross sectional area under lower temperature but higher extrusion speed.

4. Stable mechanical properties and performance can be easily achieved thanks to uniform copper flow, small extrusion hole and low residual pressure.

Technical Information of Rod Extrusion Equipment

| Model (Cu) | Rated pressure (MPa) | Size of standard copper billet (mm) | Max. circumcircle of profile (mm) | Max. width of profile (mm) | Size of die (mm) | Central height of machine (mm) | Total power (kW) | |

| Metric ton | Short ton | |||||||

| XJ-2000 | XJ-2200 | 21 | Φ203×820 | Φ95 | 95 | Φ202×120 | 1450 | 1200 |

| XJ-2200 | XJ-2400 | 21 | Φ203×870 | Φ95 | 95 | Φ202×120 | 1450 | 1200 |

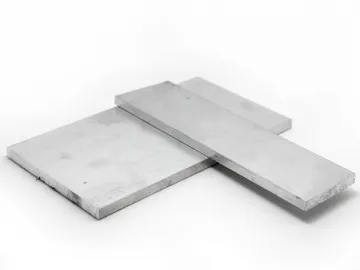

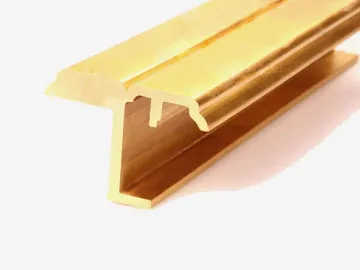

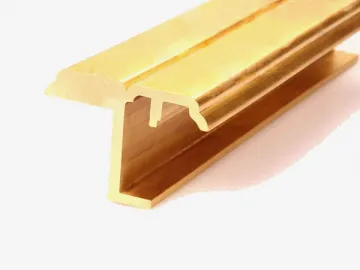

Applications

Copper rods and plates processed by this extrusion equipment find extensive application in solar energy tubes, transformers, switch gear, to name a few.

Notes

1. Limited by the hollow raw, the applied load cannot exceed a certain range.

2. Limited by the size of die, profiles with complex cross section cannot be processed.

Links:https://globefindpro.com/products/53913.html

-

Extrusion Press (for Φ170mm Rod)

Extrusion Press (for Φ170mm Rod)

-

Extrusion Press (for Φ130mm Profile / Flat Bar)

Extrusion Press (for Φ130mm Profile / Flat Bar)

-

Extrusion Press (for Φ205mm Profile / Flat Bar)

Extrusion Press (for Φ205mm Profile / Flat Bar)

-

Extrusion Press (for Φ230mm Profile / Flat Bar)

Extrusion Press (for Φ230mm Profile / Flat Bar)

-

Extrusion Press (for Φ330mm Profile / Flat Bar)

Extrusion Press (for Φ330mm Profile / Flat Bar)

-

Extrusion Press (for Φ90mm Profile / Flat Bar)

Extrusion Press (for Φ90mm Profile / Flat Bar)

-

Extrusion Press (for Φ155mm Profile / Flat Bar)

Extrusion Press (for Φ155mm Profile / Flat Bar)

-

Extrusion Press (for Φ105mm Rod)

Extrusion Press (for Φ105mm Rod)

-

Extrusion Press (for Φ280mm Profile / Flat Bar)

Extrusion Press (for Φ280mm Profile / Flat Bar)

-

Extrusion Press (for Φ310mm Profile / Flat Bar)

Extrusion Press (for Φ310mm Profile / Flat Bar)

-

Extrusion Press (for Φ260mm Profile / Flat Bar)

Extrusion Press (for Φ260mm Profile / Flat Bar)

-

Extrusion Press (for Φ130mm Profile / Flat Bar)

Extrusion Press (for Φ130mm Profile / Flat Bar)