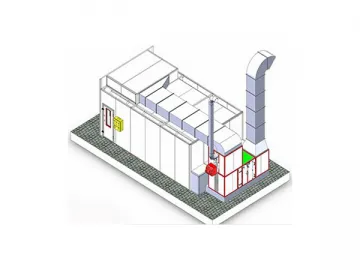

BY-10 Prep Station

Features

Due to the ventilation system on the BY-10 prep station, the pressure in the room is a negative pressure. Dust generated during the prep is effectively restricted to the prep room. Dust is then collected in the dust collection area, then emitted after being treated by the filter. The entire process effectively controls dust leakage and ensures the working environment is clean.

Parameters

| Item | Detailed Specification |

| Inside dimension | 6300×3450×2650 mm (L×W×H) |

| Outside dimension | 7550×3550×3100mm (L×W×H) |

| Plenum dimension | 6300×3450×450 mm (L×W×H) |

| Room body | Back side EPS wall panel, the other sides PVC curtain. |

| Light | Ceiling Lights: LED 8Units×4Pcs=32Pcs×36W, lighting boxes are powered coated. |

| Generator cabinet | Exhaust from back side, galvanized steel frame; white machine-made panel covered, filled with heat preservation material inside. |

| Intake and Exhaust system | 1×5.5KW turbo fan, air capacity: 18000m3/h, with electric damper. |

| Purification system | Pre-filter, ceiling filter, fiberglass filter. |

| Roof | Galvanized steel |

| Control system | Fan switch, lighting switch, emergency stop. |

| Installation method | Hooked from roof by steel cable or supported by steel column. |

| Total power | 6.7KW (Power supply 1×220V, 3×380V, 50HZ) |

Scan QR to Read

Links:https://globefindpro.com/products/54987.html

Links:https://globefindpro.com/products/54987.html

Recommended Products

Hot Products