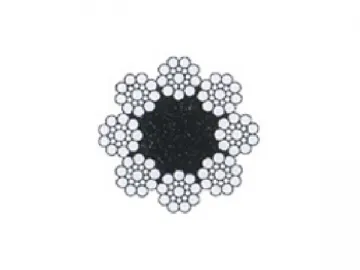

Hoist Ropes

With the advent of high rise elevator and increasing cab speed, the designers and manufacturers of elevators start to choose a higher strength hoist ropes. Junwei offers them competent elevator cables in various constructions for meeting high strength hoisting and traction. Specifications of wire ropes that Junwei supplies are shown as follows:

| 8×S(19) | 8×W(19) | 8×Fi(25) | ||||||||||

| Construction | Fiber Core 8× ( 1 9 9 ) | Construction | Fiber Core 8× { 1 6 (6 6) } | Construction | Fiber Core 8× { 1 6 (6) 12 } | |||||||

| Lay of wire rope | Ordinary lay: Z or S Lang's lay: Z or S | |||||||||||

| Nominal diameter of rope (mm) | Calculated sectional area (mm2) | Breaking load (KN) | Approx. weight per meter (kg/m) | |||||||||

| Bright Galvanized | Bright | |||||||||||

| S(19) | W(19) | Fi (25) | Grade E | Grade A | Grade B | |||||||

| 8 | 23.4 | 24.2 | 23.3 | 26 | 30.8 | 32.8 | 0.22 | |||||

| 10 | 36.5 | 37.9 | 36.5 | 40.6 | 48.1 | 51.3 | 0.343 | |||||

| 11.2 | 45.8 | 47.5 | 45.7 | 51 | 60.3 | 64.3 | 0.43 | |||||

| 12 | 52.6 | 54.5 | 52.5 | 58.5 | 69.2 | 73.8 | 0.494 | |||||

| 12.5 | 57 | 59.2 | 57 | 63.5 | 75.1 | 80.1 | 0.536 | |||||

| 14 | 71.6 | 74.2 | 71.5 | 79.6 | 94.3 | 100 | 0.672 | |||||

| 16 | 93.5 | 97 | 93.3 | 104 | 123 | 131 | 0.878 | |||||

| 18 | 118 | 123 | 118 | 132 | 156 | 166 | 1.11 | |||||

| 20 | 146 | 152 | 146 | 162 | 192 | 20.5 | 1.37 | |||||

| 22.4 | 183 | 190 | 183 | 204 | 241 | 257 | 1.72 | |||||

| 25 | 228 | 237 | 228 | 254 | 301 | 320 | 2.14 | |||||

Note:

1. The table is only for reference purposes without guarantee or warranty as to its accuracy.

2. In addition to industrial standards such as EN and JIS standards, our wire ropes can be manufactured to your individual specifications. Contact us for details.

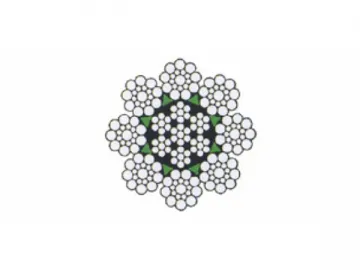

8×P·S(19)

8×P·Fi (25)

| 8×P·S(19) | 8×P·Fi (25) | ||||

| Construction | Wire ropes with special strands, fiber core 8×(1 9 9), 8×{1 6 (6) 12} | ||||

| Lay of wire rope | Ordinary lay: Z or S Lang's lay: Z or S | ||||

| Nominal diameter of rope (mm) | Calculated sectional area (mm2) | Breaking load (KN) | Approx. weight per meter (kg/m) | ||

| Bright Galvanized | |||||

| Grade E | Grade A | Grade B | |||

| 8 | 25.7 | 28.6 | 33.8 | 36.1 | 0.24 |

| 10 | 40.1 | 44.7 | 52.9 | 56.4 | 0.374 |

| 11.2 | 50.3 | 56 | 66.3 | 70.7 | 0.47 |

| 12 | 57.8 | 64.3 | 76.1 | 81.2 | 0.539 |

| 12.5 | 62.7 | 69.8 | 82.6 | 88.1 | 0.585 |

| 14 | 78.7 | 87.5 | 104 | 110 | 0.734 |

| 16 | 103 | 114 | 135 | 144 | 0.958 |

| 18 | 130 | 145 | 171 | 183 | 1.21 |

| 20 | 16 | 719 | 211 | 225 | 1.5 |

| 22.4 | 201 | 224 | 265 | 283 | 1.88 |

| 25 | 251 | 279 | 330 | 352 | 2.34 |

Note:

1. The table is only for reference purposes without guarantee or warranty as to its accuracy.

2. In addition to industrial standards such as EN and JIS standards, our wire ropes can be manufactured to your individual specifications. Contact us for details.

Links:https://globefindpro.com/products/59070.html