Metal Melting and Heating

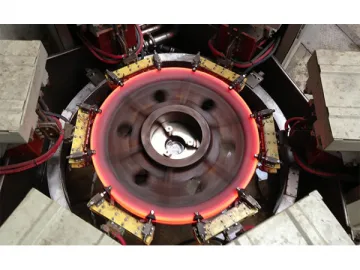

Induction Heating Machine in Metal Melting and Heating Industry

The metal melting furnace is an important independent research project of us. In this project, we are focusing on the melting, heating, and heat preservation of black or non-ferrous metal, such as iron and steel, copper, aluminum, zinc, lead, as well as alloy materials.

We have many independently developed types. The latest melting furnace has an intermediate frequency power supply that drives two furnaces to work simultaneously. Only by adjusting the power knob (or digital operation screen), you can achieve the power distribution between the two furnace. The total power can be allocated freely between the two furnaces, which enables the teamwork of melting and heat preservation respectively by the two furnaces. The continuous uninterrupted melting mode greatly improves the yields. The energy efficiency and feasibility are well-received among customers.

Features

1. Zero-voltage scanning soft start: you can start or shut down the machine at any time in any state, with no impact on the power supply;

2. Quick melting, low production costs; pollution limited in line with national environmental requirements;

3. Direct melting starting from a cold furnace, the liquid can be emptied, convenient melting material replacement;

4. Flexible power conditioning, continuous smooth adjustment; easy to control temperature uniformity, less oxidation loss, metal content uniformity;

5. Cast aluminum or steel furnace housing, small footprint; convenient furnace flip dump, options of manual, electric, hydraulic tilting methods.

| Model-Capacity | Power input (50/60HZ) | Power output | Melting time (min) | Power consumption per ton(KWH/T) | ||||||||||

| Rated power (KW) | Line voltage (V) | Line current (A) | Rectifier pulse number | Transformer rectifier capacity (KVA) | DC voltage (V) | DC current (A) | IF voltage (A) | IF frequency (KHZ) | Castiron | Copper | Brass | Aluminum | ||

| GW-0.05T | 50 | 380 | 80 | 6 | three phase 50 | 500 | 100 | 750 | 1 | 20-40 | 750 | 510 | 470 | 650 |

| GW-0.1T | 100 | 380 | 160 | 6 | three phase 100 | 500 | 200 | 750 | 1 | 20-40 | 700 | 510 | 470 | 640 |

| GW-0.15T | 160 | 380 | 256 | 6 | three phase 200 | 500 | 320 | 750 | 1 | 20-40 | 650 | 500 | 430 | 630 |

| GW-0.25T | 200 | 380 | 320 | 6 | three phase 250 | 500 | 400 | 750 | 1 | 20-45 | 650 | 500 | 420 | 610 |

| GW-0.35T | 250 | 380 | 400 | 6 | three phase 315 | 500 | 500 | 750 | 1 | 20-45 | 650 | 490 | 410 | 600 |

| GW-0.5T | 350 | 380 | 560 | 6 | three phase 400 | 500 | 700 | 750 | 0.8 | 30-50 | 630 | 480 | 400 | 570 |

| GW-0.75T | 500 | 380 | 800 | 6 | three phase 630 | 500 | 1000 | 750 | 0.8 | 40-50 | 620 | 470 | 390 | 560 |

| GW-1T | 800 | 380 | 1280 | 6 | three phase 1000 | 500 | 1600 | 750 | 0.7 | 40-50 | 620 | 460 | 380 | 550 |

| 750 | 656 | 6 | three phase 1000 | 990 | 808 | 1480 | ||||||||

| GW-1.5T | 1000 | 380 | 800 | 12 | two, three phase 1250 | 500 | 1000 | 750 | 0.7 | 40-60 | 600 | 450 | 370 | 540 |

| 750 | 820 | 6 | three phase 1250 | 990 | 1010 | 1480 | ||||||||

| GW-2T | 1400 | 750 | 1148 | 6 | three phase 1800 | 990 | 1414 | 1480 | 0.5 | 45-60 | 600 | 440 | 360 | 530 |

| 750 | 574 | 12 | two, three phase 1800 | 990 | 707 | 1480 | ||||||||

| GW-3T | 2000 | 750 | 820 | 12 | two, three phase 2500 | 990 | 1010 | 1480 | 0.5 | 50-70 | 580 | 430 | 350 | 520 |

| GW-5T | 3000 | 950 | 1140 | 12 | two, three phase 4000 | 1260 | 1190 | 1900 | 0.3 | 50-80 | 570 | 420 | 340 | 510 |

| GW-10T | 6000 | 950 | 2280 | 12 | two, three phase 8000 | 1260 | 2380 | 1900 | 0.3 | 50-90 | 560 | 410 | 330 | 490 |

| GW-15T | 8000 | 950 | 1520 | 24 | four, three phase 10000 | 1260 | 1590 | 1900 | 0.3 | 50-90 | 550 | 400 | 320 | 480 |

| GW-20T | 10000 | 950 | 1900 | 24 | four, three phase 12500 | 1260 | 1980 | 1900 | 0.25 | 50-90 | 530 | 400 | 310 | 470 |

| GW-30T | 15000 | 950 | 2850 | 24 | four, three phase 20000 | 1260 | 2980 | 1900 | 0.25 | 50-90 | 520 | 400 | 310 | 450 |

| Furnace temperature: steel 1650 ℃; cast iron 1450 ℃;copper 1150 ℃; brass 1000 ℃; aluminum 700 ℃; zinc 400 ℃ | ||||||||||||||

Links:https://globefindpro.com/products/60135.html

-

Auto Body Parts

Auto Body Parts

-

Engine Components and Parts

Engine Components and Parts

-

Induction Hardening

Induction Hardening

-

Samples of Hardened Parts

Samples of Hardened Parts

-

Corrugated Roller

Corrugated Roller

-

Large-Sized Shaft Induction Hardening Machine

Large-Sized Shaft Induction Hardening Machine

-

HKVC400/5 Induction Hardening and Tempering Machine for Chain Link

HKVC400/5 Induction Hardening and Tempering Machine for Chain Link

-

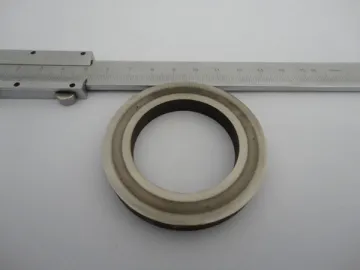

HKVP2500 Large Size Bearing Raceway Induction Hardening Machine with Slope

HKVP2500 Large Size Bearing Raceway Induction Hardening Machine with Slope

-

Gearbox System

Gearbox System

-

Auto Industry

Auto Industry

-

Induction Tempering

Induction Tempering

-

Other Industry

Other Industry