Induction Hardening

The induction hardening is the technology of heating through the induced eddy current inside the workpiece. The heated workpiece, after fast cooling, will gain significantly improved hardness, wear resistance, and other mechanical properties.

Hardening is one of our main application areas. Our induction hardening machines are playing an important role in almost every industry, with the largest market to be automotive industry. The main advantage of induction hardening is the quick process time-it takes just a few seconds. In a furnace, however, the same process will take hours.

Comparing to ordinary quenching approach, the induction quenching has the following advantages:

1. with heat concentrated on workpiece surface, fast heating, high thermal efficiency;

2. selective heating, small deformation;

3. short workpiece heating time, slight surface oxidation and decarbonization;

4. small occupied area, easy to use, good working conditions;

5. facilitate mech-automation.

Links:https://globefindpro.com/products/60138.html

-

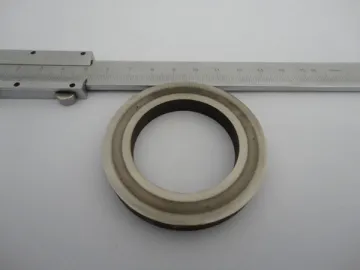

Samples of Hardened Parts

Samples of Hardened Parts

-

Corrugated Roller

Corrugated Roller

-

Large-Sized Shaft Induction Hardening Machine

Large-Sized Shaft Induction Hardening Machine

-

Metal Hardening and Tempering

Metal Hardening and Tempering

-

Inverter Drive for Reel Stand

Inverter Drive for Reel Stand

-

Trainings

Trainings

-

Engine Components and Parts

Engine Components and Parts

-

Auto Body Parts

Auto Body Parts

-

Metal Melting and Heating

Metal Melting and Heating

-

HKVC400/5 Induction Hardening and Tempering Machine for Chain Link

HKVC400/5 Induction Hardening and Tempering Machine for Chain Link

-

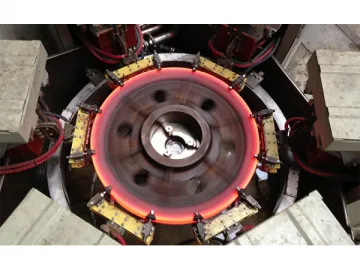

HKVP2500 Large Size Bearing Raceway Induction Hardening Machine with Slope

HKVP2500 Large Size Bearing Raceway Induction Hardening Machine with Slope

-

Gearbox System

Gearbox System