Patent

Utility Model Patent(Patent number: 200920271715.5): A Combined Type Anti-Break and Anti-Loose Wheel Nut

Technology

This utility model patent is for a combined type anti-break and anti-loose wheel nut.

Background

A wheel nut is a component of wheel bolt assembly. The existing wheel bolt and washer are separated parts, so during installation, the washer is placed first and then the nut is screwed on. The problem is that it is very difficult to take down the washer from the wheel rim, and this may lead to damage to the wheel rim. Moreover, the gap between wheel bolt and screw hole of wheel rim is pretty big, and this could break off the wheel bolt.

Summary of Invention

The utility model patent discloses a combined type anti-break and anti-loose wheel nut that overcomes the two abovementioned problems, and this is realized in the following way.

The combined type anti-break and anti-loose wheel nut contains stepped washer, arc-shaped washer and nut. On one side of the stepped washer, there is a "ladder" on which sets a straight casing, while the other side of the stepped washer is a curved face. The arc-shaped washer has a concave face that matches with the curved face of stepped washer. As for the nut, it is outfitted with a fixing ring which inserts into the arc-shaped washer and bends outwards to fasten the arc-shaped washer onto the nut, and the arc-shaped washer allows free rotation.

The positive effects of this patent are as follows: It effectively prevents the nut from loosening, increases the wheel bolt’s tensile strength, reduces the likelihood of bolt breakage when the automobile is running, and protects the wheel rim from being damaged during disassembly.

Illustrations

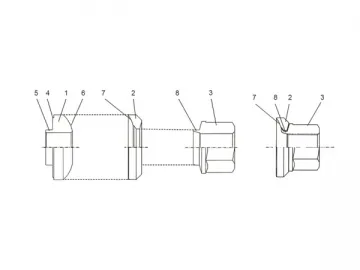

Figure 1 is the exploded view of the utility model patent.

Figure 2 is the connection diagram of nut and arc-shaped washer, where

1: stepped washer

2: arc-shaped washer

3: nut

4: "ladder"

5: straight casing

6: curved face

7: concave face

8: fixing ring

Mode of Execution

As shown in Fig.1, the claimed combined type anti-break and anti-loose wheel nut comprises of stepped washer 1, arc-shaped washer 2 and nut 3. A “ladder” 4 is set at one side of the stepped washer 1, and there is a straight casing 5 on the “ladder” 4. The other side of the stepped washer 1 has a curved face 6 which matches perfectly with the concave face 7, and the concave face 7 is on the arc-shaped washer 2. The fixing ring 8 is placed on the nut 3, and it inserts into the arc-shaped washer 2 and bends outwards to fasten the arc-shaped washer 2 onto the nut 3, and the arc-shaped washer 2 is able to rotate freely (See Fig.2).

The stepped washer must work together with the movable nut which is outfitted with arc-shaped washer. During application, the straight casing on the stepped washer should be inserted into the gap between the wheel bolt and the screw hole of wheel rim, then tighten the movable nut onto the stepped washer.

Functions of Each Part

The straight casing greatly reduces the gap between screw hole and wheel bolt, and this increases the cross sectional area when the bolt is under pressure, which in return improves the tensile strength of wheel bolt. So, the wheel bolt is far less likely to get broken when the car or truck is moving.

The concave face and curved face are combined together to add the stressed area between the bolt and the washer, thereby enhancing the binding force between them. In this way, the wheel bolt won’t get loosened automatically, and the wheel bolt is not likely to break off which is often caused by uneven force distribution.

The arc-shaped washer is pressed onto the stepped washer to avoid damage to the wheel rim.

Due to the implementation of the washer ladder, it is very easy to take out the washer at the ladder from the gap between screw hole and wheel bolt with the help of a flat head screwdriver or a crowbar. Thus, the wheel rim won’t be damaged during disassembly.

Links:https://globefindpro.com/products/61484.html