Rubber Injection Molding Machine

Modules

Technical Features

window.onload =function(){setItemByDivId('container','one|two|three|four|five|six|seven|eight|nine|ten|eleven|twelve','etw_link','color:#fff; background:#74B84B;','color:#fff;background:#F4841E','setclass');doget('/loadByJs.php?type=loadByReg&page=/product-1-1-technical-features.html/153200&start=start&end=end','setresult')}

General Options

The rubber injection molding machine can be attached with but not limited to the following items:

1. Brush device

2. Distance increase between heating platens

3. Vacuum pump for mould

4. Temperature controller for cold runner

5. Customed heating platen

6. Customed injection volume

7. KEBA i 5000 system

8. Online service

9. Multi-language controller

10. Collection control system

Related Names

Molded Rubber Making Machine | Industrial Molding Machine | Prototype Molding Equipment

Doush is a well-known manufacturer dedicated in the production of rubber injection molding machine. Through the joint development and design of Chinese and European working teams, we realize localized production and also adopt a mass of European relevant technologies, machines and top-ranging imported components. We position ourselves in manufacturing high-end products and in pursuit of excellence, devoted to providing customers with turnkey solutions.

In addition, we boast of the up-to-date management model, high-level R&D team, advanced production equipment, strict quality control system and a perfect product inspection process, which safely ensures that the technical index and performance of each device are internationally advanced, and thereby our device is applicable for various fields. We believe that you will be very satisfied with our rubber injection molding machine that features low cost but high output.

Product Features

1. This product comes in four-post structure, extremely stable and robust.

2. The mould platen is thickened and the hydraulic system is strong and reliable, both of which are maintenance-free.

3. The main piston is extra strong, providing more stable and uniform mould clamping pressure.

4. The whole device runs rapidly, quietly, smoothly and precisely.

5. The heating platen size and injection volume are optimized.

6. The operating platform is 1030mm, which is very low and thus the footboard is needless.

7. The upper and lower ejectors are provided with rack and pinion gearing stabilizers.

8. The installing holes for various auxiliary devices are reserved.

9. Maintenance can be performed with no need of disassembly.

Main Parameters

1. Precise injection volume: 350ccm-10000ccm

2. The rubber injection molding machine possesses high repeated accuracy.

3. Injection pressure: Up to 3500bar

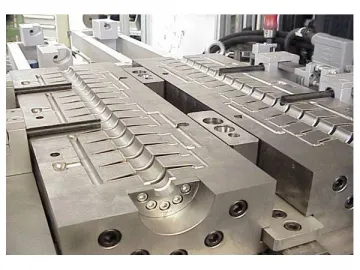

4. Heating platen: Large size, with T slot

5. Heating: 3-zone heating, with independent temperature control (Rapid heating is available.)

6. Differential heating is conducted by the heating pipe for 3 different zones.

7. Temperature difference: ±2°C

8. The rubber injection molding machine can be operated from 3 sides, i.e. front side, back side and broadside. The standard front light curtain is fitted.

9. There is a back safe door.

10. The super large mould opening stroke reaches 600mm.

Standard and Optional Configurations

Standard Configurations for 100T/160T/250T/400T Machine

1. One set of mould closing device

It requires vertical mounting and comes with hydraulic mould closing and clamping systems.

2. One set of vertical FIFO injection unit

The hydraulically driven plasticized screw is configured inside of the injection ram. Besides, the plasticized charging barrel enables both heating and refrigerating.

3. One set of hydraulic power unit

a. The hydraulic pump and the control valve work for the hydraulic system of mould closing and injection devices.

b. Two sets oil temperature machines respectively control plasticization and injection.

c. Hydraulic hanging-and-ejecting device

d. Storage cylinder with temperature indicator

e. Oil control unit

f. Hydraulic lifting devices respectively on the lower and upper mould plates

g. Lighting inside the control cabinet including limit switch

h. Front safe door

i. The energy-saving pump set is adjustable in pressure and flow.

j. USB interface

k. 3-zone heating

4. The rubber injection molding machine is also configured with the KEBA control system imported from Austria. This system is used at the microcomputer terminal for pressure closed-loop control.

a. 10 inches touch screen for data display and parameter setting

b. The display can be in both Chinese and English.

c. The data can be stored in the built-in memory card or the USB.

d. The operation sequence of the rubber injection molding machine can be set via f(x) function.

e. Both the measured value and the set value can be displayed.

f. Printer interface for recording craft adjustment

g. Injection and compression molding (ICM) program

h. Cooling control of hydraulic oil

i. Exhausting program (time control during injection)

j. Sensor for measuring mould movement and the stroke of injection ram

k. 1-10 injection phases independently set

l. 3 plasticization phases

m. 1-10 pressure maintaining phases (time control)

n. 3-zone closed-loop control of heating platen

o. Centigrade temperature display

p. Error record

Optional Configurations

The rubber injection molding machine is available with the following optional configurations:

1. Standard 100T variable pump drive

2. Servo hydraulic drive

3. Silicon filler

4. Horizontal storing device

5. Customized heating platen

6. Mobile demoulding device

7. Multilingual operation display

8. User access card

9. Material feeding and stoppage inspection device

10. 67 port in European standard

11. Front and back grating safe doors

12. Mobile device of main cylinder

13. Exchange device of double lower dies

Related Names

Hydraulic Injection Molding Machine | Injection Press | Rubber Manufacturing Equipment

Links:https://globefindpro.com/products/61530.html