Turnkey Solution

Based on abundant industry resources and extensive application cases, Doush is competent in providing turnkey solutions. Customers can send product drawings or output requirements to us and we will help you in output planning, project analysis, machine selection, mould design and fabrication, mould test and craft adjustment. We promise seriously that the mass production can be started after the whole project is completed.

Generally, the production cycle of equipment is 3 months. We will remind customers of preparing some quick-wear parts when signing contract. Surely, we will also provide some of the quick-wear parts according to actual demands.

Our agents are distributed worldwide and they directly serve customers. For special situations, Doush will assign engineers for onsite service. Usually, we provide 1 year warranty, within which we will freely replace the equipment normally damaged. Besides, custom products and moulds are available.

Details

We will recommend you with the appropriate machine according to your provided information, including:

a. Product name, application, drawing, material, performance, mould base, sample, etc.

b. Monthly or annually demanded product quantity

c. Requirements on clamping force, automation degree and injection volume

d. Mould size should be informed if only the machine is needed.

Our rubber injection molding machine is outfitted with 2 types of power systems and 2 types of injection units for your options. Diversified machine types from 50T to 600T are suitable for manufacturing rubber products in various fields.

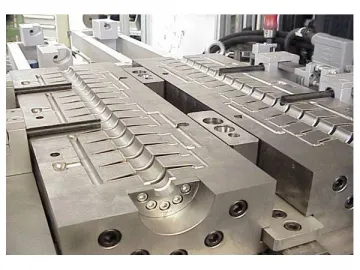

According to the mould quantity, heating platen size, product drawing and the mould base drawing offered by customers, we will select the optimal mould material and perfect cavity distribution mode for customers.

With almost 20 years of experience and a professional R&D team, we are capable of high-precision, high-level fabrication and surface finishing. Our moulds can perfectly match the machine for maximal efficacy, output increase and unit cost reduction. They can be applied to the bushing, sealing ring, silicone rubber product, damper, household appliance and other products in various fields.

We provide product analysis for customers. Taking the cold runner as an example, we will first provide the budgets of production with and without using the cold runner for your reference. Meanwhile, we will figure out the optimal solution in design based on actual situations so as to maximize the universality of cold runner. Besides, we promise that each machine will be fitted with one fixed cold runner to avoid repeated usage and reduce the cost for customers.

Our cold runner adopts the integral design, meaning that it is manufactured from one piece of platen processed by the deep hole drill. So, it is quite different from that made of 2 or three pieces of platens. It has many advantages like easy temperature control, high surface smoothness, no residual, etc. This product is also convenient for cleaning. If it has 8 cavities, 15 minutes are needed for cleaning, and 25 minutes are enough for that with 16 cavities. For the cold runner with multiple platens, the cleaning will take more than 4 hours.

Without fine injection technical guidance, desirable products are still not available even you have the good production equipment and terrific moulds. Meanwhile low output and material utilization also make most of customers upset.

Except high-quality injection equipment and moulds, Doush also provides all-around service in machine usage and maintenance. We will formulate specific technical parameters based on the equipment, mould and material characteristics to help customers in quality improvement, molding cycle shortening and post treatment reduction.

In addition, free technical support for new products is provided. For equipment installation and training, local agents will be responsible, and for special situations, we also can send engineers for onsite service.

| Object | Course | Times |

| Operation | Machine operation Alarm reset | 8 |

| Process | Parameter setting Process adjustment | 8 |

| Repair | Mechanical, hydraulic and electrical principle Daily maintenance Repair | 12 |

| Management | Efficiency improvementMachine capacity and application | 4 |

Doush offers the most perfect training for all customers. With professional training teachers, classrooms and demonstrating machines, we can provide the basic course, advanced course, maintenance course and other courses.

In addition to normal after-sales service and maintenance, Doush also provides online controller software service. Our agent network is constantly expanded all over the world, and we promise that rapid and considerate service as well as lifelong maintenance is available for all customers.

Links:https://globefindpro.com/products/61532.html