Magnetic Coagulation and Sedimentation System

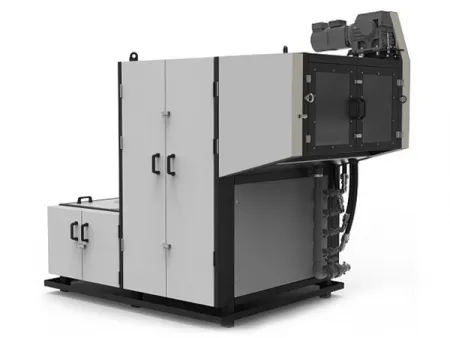

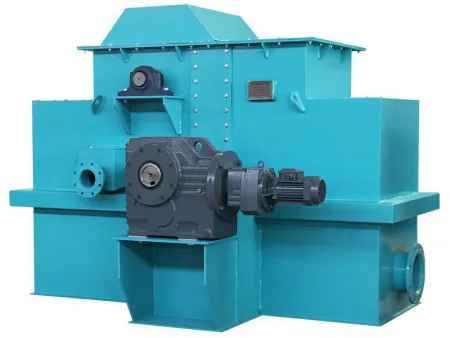

Installation and function of magnetic separator: The magnetic separator is positioned above the magnetic powder storage reaction vessel, facilitating the separation of magnetic particles and sludge.

The magnetic separator is composed of a magnetic drum, a shell, a guide plate, a polyurethane scraper, a gear motor, and other related components.

Request a Quote Performance of Magnetic SeparatorPosition and purpose of magnetic separator installation: The magnetic separator is positioned above the magnetic powder loading reaction tank to effectively separate magnetic powders from sludge.

Structure and working principle: The magnetic separator consists of a magnetic drum, shell, guide plate, polyurethane scraper, and gear motor. It utilizes the magnetic force generated by the permanent magnetic system to attract and capture the magnetic seed powders in the feed onto the surface of the magnetic drum.

Capacity: 10-40 m3/h

Magnetic roller material: S304

Magnetic flux in strong magnetic region: 3000-3500 GS

Bracket material: S304

Speed: 20-25 r/min (speed can be adjusted by frequency conversion)

Motor protection grade: IP55

Power of reducer: 1.5kW

Material of scraper: pressing plate (S304) scraper (polyurethane)

Flushing water pipe: DN25

Shell material: S304

Protection class: IP55

Links:https://globefindpro.com/products/617.html

-

Automatic Self-Cleaning Brush Screen Filter, S Series

Automatic Self-Cleaning Brush Screen Filter, S Series

-

Electric Light Duty Truck

Electric Light Duty Truck

-

Electric Light Duty Truck

Electric Light Duty Truck

-

Electric Pickup Truck

Electric Pickup Truck

-

Automatic Self-Cleaning Suction Scanning Screen Filter, X Series

Automatic Self-Cleaning Suction Scanning Screen Filter, X Series

-

Self-Cleaning Disc Filter

Self-Cleaning Disc Filter

-

Electric Light Truck

Electric Light Truck

-

Belt Filter Press, XYSD Series

Belt Filter Press, XYSD Series

-

Electric Light Duty Truck

Electric Light Duty Truck

-

Magnetic Disk Separation and Purification System

Magnetic Disk Separation and Purification System

-

Automatic Ribbon-Through Garbage Bag Making Machine

Automatic Ribbon-Through Garbage Bag Making Machine

-

Heavy Duty Garbage Bag Making Machine

Heavy Duty Garbage Bag Making Machine