Self-Cleaning Disc Filter

The self-cleaning disc filter is an efficient liquid filtering system comprising several layers of filter discs. Utilizing pressure from within the filter, liquids pass through the discs, separating solid particles and other impurities. This purification process provides clean liquid that can maintain long-term and continuous operation. Thanks to the program, cleaning of the filter elements is automated, with reverse flushing or shaking to remove the build-up of impurities. There are multiple benefits to the self-cleaning laminated filter, such as high accuracy and ease of maintenance, as well as a high degree of automation.

Precise filtration For those seeking to purify their water supply, filter discs with varying levels of accuracy are available. Options include discs with 50, 100, 200, and 400 μm precision, providing more than 85% filtration accuracy.

Thoroughly and efficiently backwashing Thanks to the centrifugal jet effect added during backwashing, the filter's pores are fully opened and the cleaning effect is improved beyond what other filters can provide. Backwashing is a quick process, taking only 10-30 seconds for each filtration unit.

A fully automated process providing continuoufreshwaterer The filtration system utilizes set timers and differential pressure control for initiating backwash cycles. Thus, the individual filter components and workstations can cycle through working and backwashing states sequentially, leading to a continuous, low-pressure water discharge. This operational method ensures effective filtration and backwashing unaffected by the duration of its use.

Modular design Users can pick the desired quantity of filter units to accommodate their needs. This provides flexibility, interchangeability and adaptability to the local workshop, taking up less ground space if required. This product requires minimal upkeep, necessitating no specialized equipment for monitoring and boasting a few removable components. Backwashing principle

When the pressure difference reaches a predetermined threshold or has passed a pre-specified period, the backwashing stage automatically begins. To reverse the water flow, the valve is controlled and the four groups of nozzles will become open, activating the piston as it moves up to break the lamination’s pressure and open up the top part. Furthermore, the backwashing water is sprayed intensely, rotating the laminations in an even manner, while the water sprays its surface and blasts off the particles stuck on it. Once the backwashing is finished, the process will then return to the filtration stage.

2" Self-Cleaning Disc FilterInlet/outlet size: 2”

Connection: grooved couplings

Filter housing material: reinforced polyamide/carbon steel/stainless steel

Disc material: PP (polypropylene)

Filtration area: 900 cm²

Filtration degree: 50μm, 100μm, 200μm, 400μm

Operating pressure: 0.25 MPa - 0.6 MPa

Backwashing pressure: ≥0.25 MPa

Backwashing cycle: 10-40 s

Backwash water consumption: ≤0.5 %

Water temperature: 5-60 ℃ Request a Quote Technical Specifications

| Good water quality | General water quality | Poor water quality | Very poor water quality | Inlet/outlet pipe diameter | |||||||||

| Filtration degree (μm) | 200 | 100 | 50 | 200 | 100 | 50 | 200 | 100 | 50 | 200 | 100 | 50 | Overall dimensions |

| Filter model | Flow rate (m³/h) | ||||||||||||

| PY2-2 | 50 | 40 | 42 | 38 | 30 | 22 | 27 | 20 | 14 | 16 | 12 | 8 | DN80 |

| PY2-3 | 75 | 60 | 42 | 57 | 45 | 33 | 40 | 30 | 22 | 24 | 19 | 13 | DN80 |

| PY2-4 | 100 | 80 | 56 | 76 | 60 | 44 | 54 | 40 | 30 | 32 | 26 | 18 | DN100 |

| PY2-5 | 125 | 100 | 60 | 95 | 75 | 55 | 67 | 50 | 37 | 40 | 32 | 22 | DN150 |

It is recommended to select the flow according to the poor water quality in the table. For other technical parameters, please consult Xuyang for details.

3" Self-Cleaning Disc FilterInlet/outlet size: 3”

Connection: grooved couplings

Filter housing material: reinforced polyamide/carbon steel/stainless steel

Filtration area: 1430 cm²

Filtration degree: 50μm, 100μm, 200μm, 400μm

Operating pressure: 0.25 MPa - 0.6 MPa

Backwashing pressure: ≥0.25 MPa

Backwashing cycle: 10-40 s

Backwash water consumption: ≤0.5 %

Water temperature: 5-60 ℃ Request a Quote Technical Specifications

| Good water quality | General water quality | Poor water quality | Very poor water quality | Inlet/outlet pipe diameter | |||||||||

| Filtration degree (μm) | 200 | 100 | 50 | 200 | 100 | 50 | 200 | 100 | 50 | 200 | 100 | 50 | Overall dimensions |

| Filter model | Flow rate (m³/h) | ||||||||||||

| PY3-3 | ≤111 | ≤90 | ≤60 | ≤84 | ≤66 | ≤48 | ≤60 | ≤45 | ≤33 | ≤36 | ≤28 | ≤19 | DN150 |

| PY3-4 | 148 | 120 | 80 | 112 | 88 | 64 | 80 | 60 | 44 | 48 | 37 | 26 | DN150 |

| PY3-5 | 185 | 150 | 100 | 140 | 110 | 80 | 100 | 75 | 55 | 60 | 47 | 32 | DN150 |

| PY3-6 | 222 | 180 | 120 | 168 | 132 | 96 | 120 | 90 | 66 | 75 | 56 | 39 | DN150/ DN200 |

| PY3-7 | 259 | 210 | 140 | 196 | 154 | 112 | 140 | 105 | 77 | 84 | 66 | 45 | DN150/ DN200 |

| PY3-8 | 296 | 240 | 160 | 224 | 176 | 128 | 160 | 120 | 88 | 96 | 75 | 52 | DN150/ DN200 |

| PY3-9 | 333 | 270 | 180 | 252 | 198 | 144 | 180 | 135 | 99 | 108 | 85 | 58 | DN200 |

| PY3-10 | 370 | 300 | 200 | 280 | 210 | 160 | 200 | 150 | 110 | 120 | 94 | 65 | DN200 |

It is recommended to select the flow according to the poor water quality in the table. . For other technical parameters, please consult Xuyang for details.

4" Self-Cleaning Disc FilterInlet/outlet size: 4”

Connection: grooved couplings

Filter housing material: carbon steel/stainless steel

Filtration area: 4250 cm²

Filtration degree: 50μm, 100μm, 200μm, 400μm

Operating pressure: 0.25 MPa - 0.6 MPa

Backwashing pressure: ≥0.25 MPa

Backwashing cycle: 10-40 s

Backwash water consumption: ≤0.5 %

Water temperature: 5-60 ℃ Request a Quote Technical Specifications

| Good water quality | General water quality | Poor water quality | Very poor water quality | Inlet/outlet pipe diameter | |||||||||

| Filtration degree (μm) | 200 | 100 | 50 | 200 | 100 | 50 | 200 | 100 | 50 | 200 | 100 | 50 | Overall dimensions |

| Filter model | Flow rate (m³/h) | ||||||||||||

| PY4-4 | 420 | 360 | 240 | 300 | 240 | 180 | 240 | 180 | 130 | 144 | 108 | 72 | DN200/DN250 |

| PY4-5 | 525 | 450 | 300 | 375 | 300 | 225 | 300 | 225 | 165 | 180 | 135 | 90 | DN200/DN250 |

| PY4-6 | 630 | 540 | 360 | 450 | 360 | 270 | 360 | 270 | 195 | 215 | 160 | 108 | DN250/ DN300 |

| PY4-7 | 730 | 630 | 420 | 520 | 420 | 310 | 420 | 310 | 230 | 250 | 185 | 126 | DN250/ DN350 |

| PY4-8 | 840 | 720 | 480 | 600 | 480 | 360 | 480 | 360 | 260 | 285 | 215 | 144 | DN300/ DN400 |

It is recommended to select the flow according to the poor water quality in the table. . For other technical parameters, please consult Xuyang for details.

10" Self-Cleaning Disc FilterInlet/outlet size: 10”

Connection: flange

Filter housing material: carbon steel/stainless steel

Filtration area: 25700 cm²

Filtration degree: 50μm, 100μm, 200μm, 400μm

Operating pressure: 0.25 MPa - 0.6 MPa

Backwashing pressure: ≥0.25 MPa

Backwashing cycle: 10-60 s

Backwash water consumption: ≤0.5 %

Water temperature: 5-60 ℃ Request a Quote Technical Specifications

| Good water quality | General water quality | Poor water quality | Very poor water quality | Inlet/outlet pipe diameter | |||||||||

| Filtration degree (μm) | 200 | 100 | 50 | 200 | 100 | 50 | 200 | 100 | 50 | 200 | 100 | 50 | Overall dimensions |

| Filter model | Flow rate (m³/h) | ||||||||||||

| PY10-4 | 2520 | 2150 | 1440 | 1800 | 1440 | 1080 | 1440 | 1080 | 790 | 860 | 640 | 430 | DN400/DN500 |

| PY10-5 | 3150 | 2700 | 1800 | 2250 | 1800 | 1350 | 1800 | 1350 | 990 | 1080 | 810 | 540 | DN500/DN600 |

| PY10-6 | 3780 | 3240 | 2160 | 2700 | 2160 | 1620 | 2160 | 1620 | 1180 | 1290 | 970 | 640 | DN600/DN700 |

| PY10-7 | 4400 | 3780 | 2520 | 3150 | 2520 | 1890 | 2520 | 1890 | 1380 | 1510 | 1130 | 750 | DN600/DN700 |

| PY10-8 | 5040 | 4300 | 2880 | 3600 | 2880 | 2160 | 2880 | 2160 | 1580 | 1720 | 1290 | 860 | DN700/DN1000 |

It is recommended to select the flow according to the poor water quality in the table. . For other technical parameters, please consult Xuyang for details. Xuyang also has 12", 8" and 6" disc filter unit options, the company has the right to modify the model and parameters without notice.

Components Disc filter shell: reinforced plastic, carbon steel coated with epoxy resin, stainless steel Pipeline: carbon steel coated with epoxy resin, stainless steel Self-cleaning device: stainless steel Three-way backwash valve: reinforced plastic, cast iron Seal ring: nitrile rubber and silicone rubber. Control box: PVC Electric automatic self-cleaning brush screen filter The setup must be arranged in a way that allows for maintenance and repair of the device without shutting off operations. This is typically achieved through the use of a bypass system. The installation position can be horizontal or vertical, depending on your specific needs. You need to ensure that your pipeline connects to the equipment following the flow of water—for a vertical setup, the inlet should point upwards, and with a horizontal one, the outlet needs to be directed downwards. The equipment must be fitted with valves for the inlet, outlet and a fast-acting drain valve for the drain outlet.Links:https://globefindpro.com/products/623.html

-

Cloth Media Disc Filter, GLD

Cloth Media Disc Filter, GLD

-

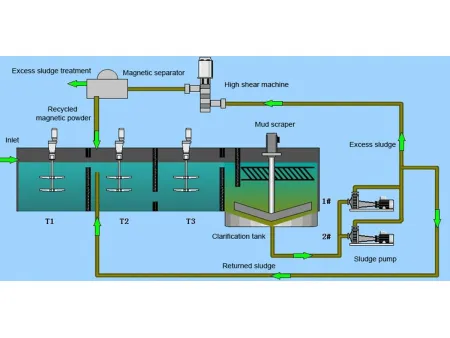

Magnetic Coagulation and Sedimentation System

Magnetic Coagulation and Sedimentation System

-

Automatic Double Line Garbage Bag on Roll Making Machine

Automatic Double Line Garbage Bag on Roll Making Machine

-

Magnetic Coagulation and Sedimentation System

Magnetic Coagulation and Sedimentation System

-

Computer Controlled T-Shirt Bag Making Machine with Hot Sealing & Hot Cutting (220pcs/min×2)

Computer Controlled T-Shirt Bag Making Machine with Hot Sealing & Hot Cutting (220pcs/min×2)

-

AGF Sand Media Filter

AGF Sand Media Filter

-

Automatic Self-Cleaning Suction Scanning Screen Filter, X Series

Automatic Self-Cleaning Suction Scanning Screen Filter, X Series

-

Electric Pickup Truck

Electric Pickup Truck

-

Electric Light Duty Truck

Electric Light Duty Truck

-

Electric Light Duty Truck

Electric Light Duty Truck

-

Automatic Self-Cleaning Brush Screen Filter, S Series

Automatic Self-Cleaning Brush Screen Filter, S Series

-

Magnetic Coagulation and Sedimentation System

Magnetic Coagulation and Sedimentation System