WE Series Dial Type Hydraulic Universal Testing Machine

1. Usage

The WE series dial type hydraulic universal testing machine is manually controlled. The dial of its dynamometer shows testing force. The product can be used in tensile, compression, bend or shear test on metallic materials. In terms of adjusting test space, it may fall into worm drive and chain drive. Measurement ranges of testing force are 100kN, 300kN, 600kN and 1000kN.

2. Main Technical Parameters of Hydraulic Universal Testing Machine With Worm Drive

| Model | Specification | WE-300 | WE-600 | WE-1000 | ||||

| Maximum testing force | 300 | 600 | 1000 | ||||

| Measurement range of testing force | 2%~10%FS, full scale consists of 1, 2 and 5 gear | ||||||

| Relative error of testing force indicating value | ≤1% indicating value | ||||||

| Transformation and amplification ratio of drawing apparatus | 2:1 or 4:1 | ||||||

| Clamp diameter of round sample (mm) | Φ10-φ32 | φ13-φ40 | φ13-φ60 | ||||

| Clamp thickness of flat sample (mm) | 0-15 | 0-30 | 0-40 | ||||

| Clamp width of flat sample (mm) | 70 | 80 | 120 | ||||

| Test space (mm) | Tensile | 800 | 880 | 800 | |||

| Compression | 700 | 800 | 670 | ||||

| Dimension of upper and lower platens (mm) | Φ130 | Φ180 | 210×210 | ||||

| Roller spacing in bending test (mm) | 30-380 | 30-380 | 50-550 | ||||

| Maximum stroke of piston (mm) | 250 | ||||||

| Power supply | 380V±10%, 50Hz | ||||||

| Working environment | 10℃~30℃, relative humidity ≤80% | ||||||

| Dimension (L×W×H)(mm) | Main engine | 900×580×2260 | 900×580×2340 | 985×650×2295 | |||

| Dynamometer | 1070×810×1730 | ||||||

| Weight (kg) | 2720 | 3000 | 4100 | ||||

3. Functions and Characteristics of Hydraulic Universal Testing Machine

1) Main Engine

a) With hydro-cylinder underneath, the structure is compact and reasonable. It considerably reduces the height of the machine without changing test space, compared with the one with hydro-cylinder overhead.

b) Adopting worm drive mechanism with crosswise moving beam to adjust test space, instead of chain drive mechanism, the product allows adjusting test space with no need for screw rotation. Its drive system is completely separated from positioning system, and the geometric center of loading system is identical to the center of stressed position, which guarantees coaxiality between upper and lower jaws, and durability of the main engine.

c) The independent hydraulic clamping mechanism ensures reliability of clamping system. Even though the sample is snapped, it will not drop or hurt testers.

2) Dynamometric System

a) The dynamometer and main engine are independent of each other, and connected to one other by a fuel injection pipe and wires. Such a design avoids any influence upon the reading of dynamometer from great shock caused by sample snapping, which makes sure the reading is accurate and reliable.

b) The dial for indicating testing force comes with closed structure and clear ruling.

c) Equipped with a loading speed indicator, the product is easy to operate and able to reach 0.4rpm, 0.8rpm or 2 rpm.

WE-B Series Chain Drive Dial Type Hydraulic Universal Testing Machine

1. Main Technical Parameters of WE-B Series Hydraulic Universal Testing Machine With Chain Drive

| ModelSpecification | WEW-100B | WEW-300B | WEW-600B | WEW-1000B | ||||

| Maximum testing force (kN) | 100 | 300 | 600 | 1000 | ||||

| Measurement range of testing force | 2%~10%FS, full scale consists of 1, 2, 5 and 10 gear | |||||||

| Relative error of testing force indicating value | ≤1% indicating value | |||||||

| Accuracy of deformation measurement | ±0.5%FS | |||||||

| Clamp diameter of round sample (mm) | Φ6-Φ22 | Φ10-φ32 | φ13-φ40 | φ13-φ60 | ||||

| Clamp thickness of flat sample (mm) | 0-15 | 0-15 | 0-30 | 0-40 | ||||

| Clamp width of flat sample (mm) | 60 | 70 | 80 | 120 | ||||

| Test space (mm) | Tensile | 610 | 440 | 580 | 550 | |||

| Compression | 520 | 350 | 480 | 580 | ||||

| Dimension of upper and lower platens (mm) | Φ100 | Φ130 | Φ180 | 210×210 | ||||

| Roller spacing in bending test (mm) | 30-300 | 30-380 | 30-380 | 50-550 | ||||

| Maximum stroke of piston (mm) | 150 | 250 | ||||||

| Power supply | 380V±10%,50Hz | |||||||

| Working environment | 10℃~30℃, relative humidity ≤80% | |||||||

| Dimension (L×W×H)(mm) | Main engine | 730×500×1930 | 900×580×2265 | 900×580×2340 | 985×650×2295 | |||

| Control cabinet | 550×550×1130 | 600×600×1165 | ||||||

| Weight (kg) | 1350 | 2720 | 3000 | 4100 | ||||

2. Functions and Characteristics of Dial Type Hydraulic Universal Testing Machine

1) Main Engine

It belongs to chain drive method.

2) Dynamometric System

a) The dynamometer is independent of the main engine. They are linked by a fuel injection pipe and wires to protect the reading of dynamometer from being affected by great shock when the sample snaps. Therefore, the reading can be precise and reliable.

b) With clear scale, the dial for indicating testing force adopts closed structure.

c) Its loading speed indicator is conducive to easy operation. Optional speeds are 0.4rpm, 0.8rpm or 2 rpm.

Related Names

Tensile Stress Tester | Concrete Testing Machine | Compression Test Equipment

Links:https://globefindpro.com/products/61734.html

-

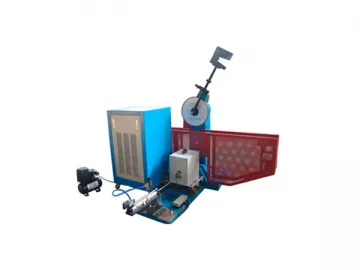

Impact Testing Machine

Impact Testing Machine

-

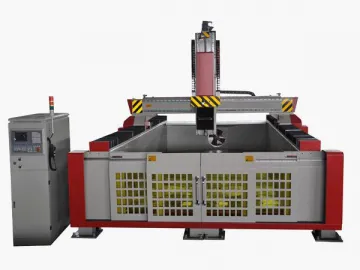

Styrofoam Machining Center

Styrofoam Machining Center

-

Stress Relaxation Testing Machine

Stress Relaxation Testing Machine

-

Computer Control Automatic Low Temperature Impact Testing Machine

Computer Control Automatic Low Temperature Impact Testing Machine

-

Shear Testing Machine

Shear Testing Machine

-

Laser Engraving Machine

Laser Engraving Machine

-

Hydraulic Universal Testing Machine

Hydraulic Universal Testing Machine

-

CW Series Door and Window Physical Property Tester

CW Series Door and Window Physical Property Tester

-

Steel Rebar Bending Testing Machine

Steel Rebar Bending Testing Machine

-

XYJ Series Door and Window Angle Strength Tester

XYJ Series Door and Window Angle Strength Tester

-

CNC Engraving and Milling Machine

CNC Engraving and Milling Machine

-

Rolling Wear and Tear Testing Machine

Rolling Wear and Tear Testing Machine