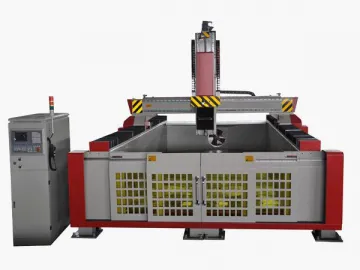

CW Series Door and Window Physical Property Tester

1. Main Usage

The CW series door and window physical property tester is used to test gas tightness, water tightness and wind pressure resistance performance of the external doors and windows of buildings. In accordance with GB/T7106-2008, it is highly suitable for constructional engineering quality testing departments, product quality testing departments, universities, and aerospace research and development institutions. All the products belong to computer-aided design and manufacturing, and are detected by advanced measuring instruments through effective detection means.

2. Key Technical Parameters of Door and Window Physical Property Tester

1) Supply range of water spraying in water tightness test: 100~1000L/h

(a) Accuracy class: 1.5

(b) Range of sprayed water quantity: 2~3L/m².min

(c) Pressure fluctuation range of water tightness: 50Pa~ 1500Pa

2) Measurement range of air flow: 0~650m3/h; Accuracy class: ≤ 5%

3) Wind pressure range and adjustable range: -5000Pa~ 5000Pa

(a) Sensor accuracy: ±0.3%

(b) Precision of voltage stabilization: ≤ 2%; Resolution of pressure: 1Pa

4) Displacement range: ±50mm; Displacement resolution: 0.01mm; Precision: ±0.1%FS

5) Pressure fluctuation: Period of fluctuation: 3s~5s; Fluctuation time per level: 5min

6) Control mode: Microcomputer fully automatic CNC fully automatic

7) Power supply: 380V±10%, 50HZ; Power: 12KW

8) Dimension of plenum chamber: 3000×1700×2900

9) Dimension of external windows to be tested: 0.6m×0.6m~2.4m×2.4m or 0.6m×0.6m~3.0m×3.0m

3. Functions and Characteristics

1) Precision

The physical property tester can sample rapidly in real time. The system can synchronously acquire signals from all the sensors, and communicate through high-speed Ethernet which improves the accuracy of measurement and control.

2) Convenience

a) Its full-digital embedded measurement and control system realizes dual displays, dual control and "one-button" operation, which greatly facilitate testing operation. For example, if you want to conduct a wind pressure resistance test in microcomputer fully automatic mode, you can just press the Start button and then the product will automatically go through the overall testing process.

b) Spraying is controlled by the button which is conducive to easy operation. The spray header is under the control of a solenoid valve. You may control spraying through buttons according to the sizes of test specimens shown on the panel.

Related Names

Mechanical Testing Equipment | Tightness Test Machine | Leakage Tester

Links:https://globefindpro.com/products/61732.html

-

Hydraulic Universal Testing Machine

Hydraulic Universal Testing Machine

-

WE Series Dial Type Hydraulic Universal Testing Machine

WE Series Dial Type Hydraulic Universal Testing Machine

-

Impact Testing Machine

Impact Testing Machine

-

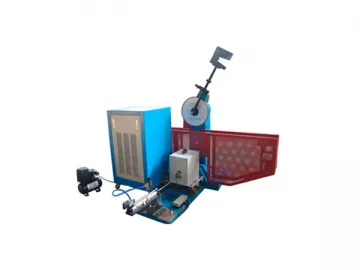

Styrofoam Machining Center

Styrofoam Machining Center

-

Stress Relaxation Testing Machine

Stress Relaxation Testing Machine

-

Computer Control Automatic Low Temperature Impact Testing Machine

Computer Control Automatic Low Temperature Impact Testing Machine

-

Steel Rebar Bending Testing Machine

Steel Rebar Bending Testing Machine

-

XYJ Series Door and Window Angle Strength Tester

XYJ Series Door and Window Angle Strength Tester

-

CNC Engraving and Milling Machine

CNC Engraving and Milling Machine

-

Rolling Wear and Tear Testing Machine

Rolling Wear and Tear Testing Machine

-

Double-head Water-slot Milling Machine (Three Spindles)

Double-head Water-slot Milling Machine (Three Spindles)

-

LJB2-350×3500 Double Mitre Saw

LJB2-350×3500 Double Mitre Saw