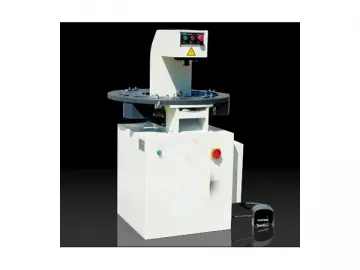

XWY-300 Series Thermal Deformation and Vicat Softening Point Tester

1. Main Usage

The XWY-300 series thermal deformation and vicat softening point tester is suitable for various non-metallic materials, such as plastics, rubber, nylon, electrical insulating materials and so on.

2. Major Technical Parameters

1) Accuracy of deformation measurement: 0.01mm

2) Measurement range: Room temperature ~300℃

3) Accuracy of temperature: ±0.5℃

4) Temperature resolution: 0.1℃

5) Temperature rising speed: 5O℃±5℃/1h or 120℃±10℃/1h

6) Accuracy of deformation: ±0.01mm

7) Display resolution of deformation: 0.001mm

8) Range of static load: 1000±5g or 5000±5g

9) Heating medium: Methyl silicone oil or transformer oil

10) Experimental unit: 3 routes

11) Displacement display method: Dual displays (digital display and screen display), etc.

12) Power of heater: 3000W/220V

13) Dimension: 520×520×1100mm

14) Brand-name computer and 19-inch LCD

15) Color inkjet printer: HP

16) Weight: 220kg

3. Functions and Characteristics

1) The product acquires the variation of temperature and deformation, and control the whole process through a computer. It can display curves of test processes in real time and print results.

2) Its dedicated displacement sensor ensures precise tests and reliable operation.

3) The sample holder is able to automatically and stably rise or lower without any noise.

4) You can easily install samples. After clamping a sample, the system starts to test automatically.

5) Due to a cooling system, the thermal deformation and vicat softening point tester can rapidly cool the heating medium, which avoids a pause between two sets of tests and greatly promotes testing efficiency.

Related Names

Softening Temperature Plastic Tester | Thermal Tester | Polymer Testing Machine

Links:https://globefindpro.com/products/61760.html

-

Hydraulic Compression Testing Machine

Hydraulic Compression Testing Machine

-

Corner Cleaning Machine (for up/bottom surface)

Corner Cleaning Machine (for up/bottom surface)

-

PVC Profile Milling Machine

PVC Profile Milling Machine

-

Four Point Welding Machine

Four Point Welding Machine

-

Punching Machine

Punching Machine

-

CNC Profile Drilling Machine

CNC Profile Drilling Machine

-

Automatic Corner Key Cutting Machine

Automatic Corner Key Cutting Machine

-

Semi-automatic Impact Testing Machine

Semi-automatic Impact Testing Machine

-

Material Testing Machine

Material Testing Machine

-

Wood CNC Machining Center

Wood CNC Machining Center

-

WEW Series Screen Display Type Hydraulic Universal Testing Machine

WEW Series Screen Display Type Hydraulic Universal Testing Machine

-

NJS Series Torsion Testing Machine

NJS Series Torsion Testing Machine