WAW Series Computerized Electro-hydraulic Servo Universal Testing Machine

1. Equipment Usage

The WAW series electro-hydraulic servo universal testing machine displays force values and curves through a computer. The product is used for tensile, compression, bend and shear tests on metallic materials. In addition, it is able to do fracture resistance and compression resistance tests on cement, concrete and other non-metallic materials. With the help of special-purpose auxiliary tools, it also applies to mechanical property tests on fasteners, steel wire ropes and constructional elements. Therefore, it is ideal for aerospace departments, project quality testing, colleges, industrial and mining enterprises, and research and development institutions. In order to satisfy your varied demands, the machine supports testing in accordance with several test standards, like ISO, ASTM, JIS and EN. Its force measurement range covers 300kN, 600kN, 1000kN and 2000kN.

2. Main Technical Parameters of Electro-hydraulic Servo Universal Testing Machine

| Model | Specification | WAW-300 | WAW-600 | WAW-1000 | |

| Maximum testing force | 300 | 600 | 1000 | |

| Measurement range of testing force | 2%~10%FS, full scale consists of 1, 2, 5 and 10 gear | |||

| Relative error of testing force indicating value | ≤1% indicating value | |||

| Measurement resolution of displacement | 0.01mm | |||

| Accuracy of deformation measurement | ±0.5%FS | |||

| Control range of stress rate | 1MP/S-60MP/S | |||

| Adjustable range of test strain rate | 0.00025/S-0.0025/S | |||

| Control range of displacement rate | 0.5mm /min-50mm/min | |||

| Clamp diameter of round sample (mm) | φ10- φ32 | φ13- φ40 | φ13- φ60 | |

| Clamp thickness of flat sample (mm) | 0-15 | 0-30 | 0-40 | |

| Clamp width of flat sample (mm) | 70 | 80 | 120 | |

| Test space (mm) | Tensile | 750 | 800 | 650 |

| Compression | 650 | 700 | 600 | |

| Dimension of upper and lower platens (mm) | Φ130 | Φ180 | 210 ×210 | |

| Roller spacing in bending test (mm) | 30-580 | 30-580 | 30-800 | |

| Maximum stroke of piston (mm) | 250 | |||

| Power supply | 380V ±10%,50Hz | |||

| Working environment | 10 ℃ ~30℃, relative humidity≤80% | |||

| Dimension (L ×W ×H) (mm) | Main engine | 905 ×580 ×2260 | 905 ×580 ×2325 | 1070 ×850 ×2530 |

| Control cabinet | 600 ×600 × 1165 | |||

| Weight (kg) | 2720 | 3000 | 4100 | |

3. Key Features of Electro-hydraulic Servo Universal Testing Machine

1) Compact Structure

The structure is compact and reasonable with a hydro-cylinder underneath the main engine. You can easily install the product.

2) It adjusts test space through worm drive mechanism that traverses moving beam. This design is able to adjust test space without revolving the screw, absolutely separate drive system from positioning system, and make sure the geometric center of loading system accords with the center of stressed position, which contributes to the concentricity between upper and lower jaws, and wear of the main engine. The unique elimination mechanism of screw clearance enables tests to be loaded continuously.

3) Load Measurement

The electro-hydraulic servo universal testing machine is praised for the high-accuracy oil pressure sensor, high linear repeatability, considerable shock resistance, great stability and long working life.

4) Displacement Measurement

The imported optical-electricity encoder guarantees precise and steady displacement measurement.

5) Deformation Measurement

The strain extensometer is applied due to high precision, cost saving and practical application.

Related Names

Dynamic Testing Machine | Endurance Test Machine | Pull Test Equipment

Links:https://globefindpro.com/products/61771.html

-

Aluminum Window Door Double Head Corner Crimping Machine

Aluminum Window Door Double Head Corner Crimping Machine

-

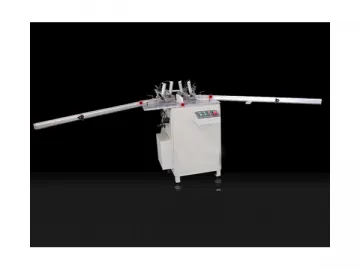

Precise Double Mitre Saw

Precise Double Mitre Saw

-

End Milling Machine

End Milling Machine

-

Automatic Feed Aluminum Door Window Double Head Corner Crimping Machine

Automatic Feed Aluminum Door Window Double Head Corner Crimping Machine

-

Aluminium Windows and Doors Glazing Bead Cutting Saw

Aluminium Windows and Doors Glazing Bead Cutting Saw

-

Auto Screw Fastening Machine

Auto Screw Fastening Machine

-

Aluminum Alloy Profile Cutting Machine

Aluminum Alloy Profile Cutting Machine

-

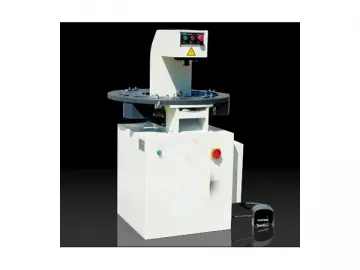

Corner Crimping Machine

Corner Crimping Machine

-

YES Series Digital Display Type Hydraulic Compression Testing Machine

YES Series Digital Display Type Hydraulic Compression Testing Machine

-

Corner Cleaning Machine

Corner Cleaning Machine

-

CNC Profile Drilling Machine

CNC Profile Drilling Machine

-

Punching Machine

Punching Machine