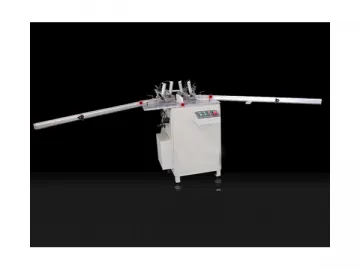

Automatic Feed Aluminum Door Window Double Head Corner Crimping Machine

1. Introduction

1) The double head corner crimping machine can feed automatically and process aluminium doors and windows. It is applied for riveting and crimping corners in double heads of frames or sashes synchronously, and may machine two corners at a time.

2) Owing to its plunger type hydraulic system, the product is praised for efficient rivet punching and firm corner connecting.

3) The operator can adjust the hold-down and positioning device in the vertical direction, so as to process profiles with diverse specifications and sections.

4) The unique double foot valve design makes pre-compaction more effective, facilitates cutting feed and corner crimping, and reduces the rejection rate.

5) It adds an auxiliary compression mechanism to help to feed materials.

2. Technical Parameters of Double Head Corner Crimping Machine

1) Error of diagonal gap:≤0.15mm

2) Power supply:380V 50Hz , three-phase four-wire

3) Pressure of hydraulic system:15Mpa

4) Working pressure:0.5-0.8Mpa

5) Air consumption:0.2L per time

6) Oil tank capacity:40L

7) Maximum distance between two spindles:3000mm 3500mm

8) Minimum size of assembled frame:450mm

9) Width of machinable profile:100mm

10) Dimension:4100mm x 1000mm x 1600mm

11) Weight: 1000Kg

Related Names

Aluminum Crimping Equipment | Metal Door Corner Assembly | Residential Window Corner Connector

Links:https://globefindpro.com/products/61775.html

-

Aluminium Windows and Doors Glazing Bead Cutting Saw

Aluminium Windows and Doors Glazing Bead Cutting Saw

-

Auto Screw Fastening Machine

Auto Screw Fastening Machine

-

WDW-G Series Computerized Electronic Universal Testing Machine

WDW-G Series Computerized Electronic Universal Testing Machine

-

PVC Windows and Doors Fabricating Machine

PVC Windows and Doors Fabricating Machine

-

Aluminum Profile Corner Key Cutting Saw

Aluminum Profile Corner Key Cutting Saw

-

LDX-250 Automatic End Milling Machine

LDX-250 Automatic End Milling Machine

-

End Milling Machine

End Milling Machine

-

Precise Double Mitre Saw

Precise Double Mitre Saw

-

Aluminum Window Door Double Head Corner Crimping Machine

Aluminum Window Door Double Head Corner Crimping Machine

-

WAW Series Computerized Electro-hydraulic Servo Universal Testing Machine

WAW Series Computerized Electro-hydraulic Servo Universal Testing Machine

-

Aluminum Alloy Profile Cutting Machine

Aluminum Alloy Profile Cutting Machine

-

Corner Crimping Machine

Corner Crimping Machine