WDW-G Series Computerized Electronic Universal Testing Machine

1. Equipment Usage

The WDW-G series electronic universal testing machine is computerized, and applicable to bend, shear, peel, tear and other tests on multiple metallic or non-metallic materials, such as springs, rubber, electric wires, composite materials, plastic profiles and constructional elements. Several test standards are available, including GB, ISO, JIS, DIN, ASTM and so on.

2. Measured Parameters of Computerized Electronic Universal Testing Machine

1) Maximum testing force: 10, 20kN

2) Grade of testing machine: 0.5

3) Relative error of testing force indicating value: ±0.5%

4) Resolution of testing force: 1/500000 (500000 code)

5) Measurement range of testing force: 0.2%~100%F.S the whole process applies the same gear and invariant resolution

6) Relative error of deformation indicating value: ±0.5%

7) Measurement rage of deformation: 0.2%~100%F.S

8) Relative error of large deformation indicating value: ±0.5%

9) Resolution of large deformation: 0.003mm

10) Measurement range of large deformation: 0-800mm

11) Relative error of displacement indicating value: ±0.3%

12) Resolution of displacement: 0.000025mm

13) Adjustable range of testing force rate control: 0.005~10%F.S/s

14) Relative error of testing force rate control: Rate <0.05%F.S/s, error = ±1%; Rate > 0.05%F.S/s, error = ±0.5%

15) Adjustable range of strain rate control: 0.005~10%F.S/s

16) Relative error of strain rate control: Rate < 0.05%F.S/s, error = ±1%; Rate > 0.05%F.S/s, error = ±0.5%

17) Adjustable range of displacement rate control: 0.001~500mm/min

18) Relative error of displacement rate control: ±0.5%

19) Control range of keeping force, deformation and displacement: 0.3%~100%F.S

20) Relative error of keeping force, deformation and displacement: Set value < 10%FS, relative error≤ 1% set value; Set value≥10%FS, relative error≤ 0.5% set value

21) Beam stroke (no clamp): 1100mm

22) Compression space: 10kN: 800mm; 20kN: 880mm

23) Tensile space: 10kN: 700mm; 20kN: 780mm

24) Width of test space: 420mm

25) Working environment: Room temperature~30℃; relative humidity≤80%

3. Main Parts of Computerized Electronic Universal Testing Machine

1) Main engine: Double space

2) Servo driver and servomotor: Imported

3) Sensor: Celtron

4) Screw: Precise ball screw

5) Linear guiding device: Making beam steady during runtime

6) Safety protection: Bullet-proof glass shield

7) Remote control: Controlling rise and fall of the beam

8) Standard accessories: Tensile, compression, bend clamp

9) Dedicated teat software: Tensontest2

Related Names

Tensile Strength Testing Equipment | Shear Testing Machine | Creep Test Machine

Links:https://globefindpro.com/products/61778.html

-

PVC Windows and Doors Fabricating Machine

PVC Windows and Doors Fabricating Machine

-

Aluminum Profile Corner Key Cutting Saw

Aluminum Profile Corner Key Cutting Saw

-

LDX-250 Automatic End Milling Machine

LDX-250 Automatic End Milling Machine

-

LWJ-100 Profile Bending Machine

LWJ-100 Profile Bending Machine

-

Aluminium Profile Variable Punching Machine

Aluminium Profile Variable Punching Machine

-

YAW Series Computerized Electro-hydraulic Compression Testing Machine

YAW Series Computerized Electro-hydraulic Compression Testing Machine

-

Auto Screw Fastening Machine

Auto Screw Fastening Machine

-

Aluminium Windows and Doors Glazing Bead Cutting Saw

Aluminium Windows and Doors Glazing Bead Cutting Saw

-

Automatic Feed Aluminum Door Window Double Head Corner Crimping Machine

Automatic Feed Aluminum Door Window Double Head Corner Crimping Machine

-

End Milling Machine

End Milling Machine

-

Precise Double Mitre Saw

Precise Double Mitre Saw

-

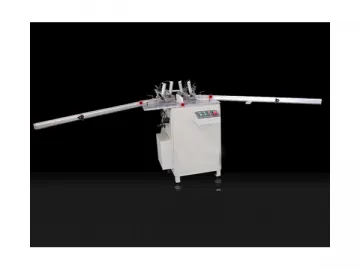

Aluminum Window Door Double Head Corner Crimping Machine

Aluminum Window Door Double Head Corner Crimping Machine