WLW Series Horizontal Tensile Testing Machine

1. Main Usage

The WLW-2000 horizontal tensile testing machine is mainly applied to test tensile strength of electric cables, optical cables, steel wire ropes, steel strand and other kinds of ropes. Its main engine takes advantage of several advanced technologies, including hydraulic cylinder loading, force measuring by load cell, microprocessor control, and displaying and printing test results.

2. Major Technical Parameters of Horizontal Tensile Testing Machine

1) Maximum testing force: 2000kN

2) Range of testing force: 2%-100%

3) Precision of testing range: ≤1% indicating value

4) Piston stroke: 1500mm

5) Measure range of displacement: 0-1500mm

6) Measurement accuracy of displacement: ≤ 0.5%FS

7) Resolution of displacement: ≤ 0.05mm

8) Piston movement speed: Tensile process: 0-90mm/min

9) Maximum tensile test space: 12000mm

10) Minimum clamping distance: 500mm

11) Regulating method and range of space: Fixed inserted pin; 4 groups; 20 location holes (the distance between 2 holes is 500mm, hierarchically adjusting positions)

12) Dimension of main engine(L×W×H): 19900x1900x1455mm

13) Weight of main engine: About 21000kg

14) Electro-hydraulic power: 10kW

3. Features

1) The horizontal tensile testing machine is appropriate for a wide range of materials, such as steel wire ropes, anchor chains, electric wires, webbing slings, nylon ropes, chains and other long samples.

2) Its tensile space and hydro-cylinder stroke can be customized to satisfy your needs.

3) You can also have the tonnage of test force made to order, which consists of 1000kN, 2000kN, 3000kN, 4000kN, etc.

4) With a steady structure, the main engine puts a high-accuracy load cell to use, which does well in accuracy and stability.

5) With the CE marking, the products can be exported to EU countries.

Related Names

Tensile Tester | Pull Test Machine | Cable Tensile Test Device

Links:https://globefindpro.com/products/61806.html

-

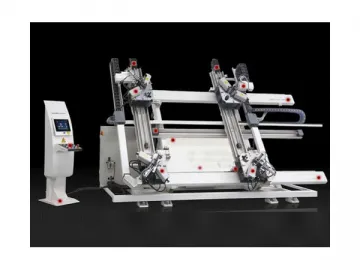

Aluminum Door Window Four Head Automatic Corner Crimping Machine

Aluminum Door Window Four Head Automatic Corner Crimping Machine

-

T Locking Plate I

T Locking Plate I

-

Proximal Humeral Locking Plate II Type

Proximal Humeral Locking Plate II Type

-

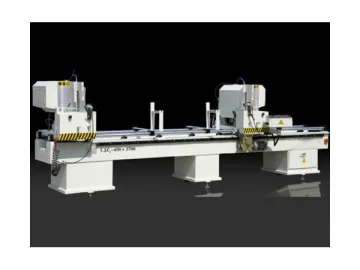

SAW KING Double Head Saw

SAW KING Double Head Saw

-

Wood Furniture CNC Router

Wood Furniture CNC Router

-

XGY Series Plastic Pipe Withstanding Pressure Testing Machine

XGY Series Plastic Pipe Withstanding Pressure Testing Machine

-

Dropping Ball Impact Testing Machine

Dropping Ball Impact Testing Machine

-

V Corner Cleaning Machine

V Corner Cleaning Machine

-

WAW-G Series Computerized Electro-hydraulic Servo Universal Testing Machine

WAW-G Series Computerized Electro-hydraulic Servo Universal Testing Machine

-

Distal Medial Tibial Locking Plate

Distal Medial Tibial Locking Plate

-

Full-load Test Platform

Full-load Test Platform

-

Single Head Variable Angle Welding Machine

Single Head Variable Angle Welding Machine