D-Series High Speed Paperboard Printing Slotting and Die Cutting Machine

20mm.

3. The paperboard printing machine unit is equipped with a pneumatic diaphragm pump for ink supply, and the ink cup can show the ink level.

4. It is designed with a printing plate hanging apparatus with whole- or half-plate hanging groove. Also, it comes with a foot pedal to control the rotation direction of the printing cylinder, which makes printing plate mounting and dismounting convenient.

5. A self-locked worm and gear mechanism is adopted to adjust or fix the gap between the anilox roller and rubber roller, the gap between the paperboard and the creasing wheel, as well as the gap between paper guide rollers.

6. The fixation of the printing roller rotation angle is achieved via a pneumatic braking system. When the carton making machine stops working, the braking system will force the main motor to stop running, thus keeping the gear position fixed.

7. The paperboard printing machine can be optionally designed with printing cylinder rotation position memory and resetting functions.

8. The printing rubber roller is constructed of a steel pipe coated with wearing resistant rubber. Through special grinding and polishing, it offers good ink transfer performance.

9. The anilox roll also comes with a steel core which is fine polished, and it is finally coated with a layer of hard chrome plating to assure better abrasion resistance.

10. The high speed paperboard printing equipment has a pneumatic printing plate lifting device. When the main machine stops working, the anilox roll will be pneumatically separated from the rubber roller, and meanwhile, ink distribution function is available to avoid ink drying up.

Paperboard Slotting Unit

1. Similar to the printing unit, the paperboard slotting machine is equipped with a planetary gear mechanism to control the cutter head’s rotation angle.

2. The transverse movement of the slotting tool rest and creasing wheel is adjustable via manual and mechanical combined method.

3. The slotting tool position can be adjusted in accordance with the height of boxes.

4. This unit is designed with a self-locking type worm and gear mechanism to adjust and fix the creasing wheel height according to the paperboard thickness, thus assure high quality creasing.

5. The elastic cutting knife design allows for simple cutting of three-ply or five-ply paperboard without any additional adjustment.

6. The knife is made of superior quality alloy steel, and undergoes heat treatment and surface grinding. This assures wonderful hardness and tensile strength, achieving long service life.

7. According to clients’ demands, the paperboard slotting machine can be optionally equipped with perforating function to create hand holes for easy lifting of boxes. Electric controlled, single shaft slotting adjustment function, and electric controlled slotting knife horizontal movement function are optional as well.

3. The paperboard printing machine unit is equipped with a pneumatic diaphragm pump for ink supply, and the ink cup can show the ink level.

4. It is designed with a printing plate hanging apparatus with whole- or half-plate hanging groove. Also, it comes with a foot pedal to control the rotation direction of the printing cylinder, which makes printing plate mounting and dismounting convenient.

5. A self-locked worm and gear mechanism is adopted to adjust or fix the gap between the anilox roller and rubber roller, the gap between the paperboard and the creasing wheel, as well as the gap between paper guide rollers.

6. The fixation of the printing roller rotation angle is achieved via a pneumatic braking system. When the carton making machine stops working, the braking system will force the main motor to stop running, thus keeping the gear position fixed.

7. The paperboard printing machine can be optionally designed with printing cylinder rotation position memory and resetting functions.

8. The printing rubber roller is constructed of a steel pipe coated with wearing resistant rubber. Through special grinding and polishing, it offers good ink transfer performance.

9. The anilox roll also comes with a steel core which is fine polished, and it is finally coated with a layer of hard chrome plating to assure better abrasion resistance.

10. The high speed paperboard printing equipment has a pneumatic printing plate lifting device. When the main machine stops working, the anilox roll will be pneumatically separated from the rubber roller, and meanwhile, ink distribution function is available to avoid ink drying up.

Paperboard Slotting Unit

1. Similar to the printing unit, the paperboard slotting machine is equipped with a planetary gear mechanism to control the cutter head’s rotation angle.

2. The transverse movement of the slotting tool rest and creasing wheel is adjustable via manual and mechanical combined method.

3. The slotting tool position can be adjusted in accordance with the height of boxes.

4. This unit is designed with a self-locking type worm and gear mechanism to adjust and fix the creasing wheel height according to the paperboard thickness, thus assure high quality creasing.

5. The elastic cutting knife design allows for simple cutting of three-ply or five-ply paperboard without any additional adjustment.

6. The knife is made of superior quality alloy steel, and undergoes heat treatment and surface grinding. This assures wonderful hardness and tensile strength, achieving long service life.

7. According to clients’ demands, the paperboard slotting machine can be optionally equipped with perforating function to create hand holes for easy lifting of boxes. Electric controlled, single shaft slotting adjustment function, and electric controlled slotting knife horizontal movement function are optional as well.

Scan QR to Read

Links:https://globefindpro.com/products/62808.html

Links:https://globefindpro.com/products/62808.html

Recommended Products

-

Engineering Dump Truck

Engineering Dump Truck

-

Other Pictures

Other Pictures

-

4870Kg Fuel Tank Truck

4870Kg Fuel Tank Truck

-

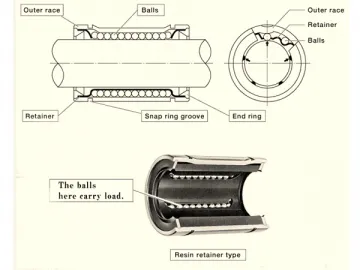

Linear Bearing

Linear Bearing

-

SM-E Corrugated Paperboard Double Facer

SM-E Corrugated Paperboard Double Facer

-

Hotel Chain in Mexico

Hotel Chain in Mexico

-

SF-380S/405S Type Fingerless Single Facer For Corrugated Paperboard

SF-380S/405S Type Fingerless Single Facer For Corrugated Paperboard

-

Road Wrecker

Road Wrecker

-

NC Corrugated Board Helical Cross Cutting Machine

NC Corrugated Board Helical Cross Cutting Machine

-

G-Series High Speed Paperboard Printing Slotting and Die Cutting Machine

G-Series High Speed Paperboard Printing Slotting and Die Cutting Machine

-

Truck Mounted Crane

Truck Mounted Crane

-

Refrigerated Truck

Refrigerated Truck