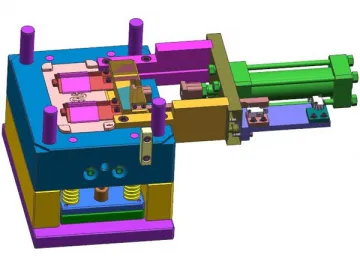

Business Card Holder Mold

Business Card Holder Mold

The business card holdermold applies polystyrene (PS) in the manufacture of business card holder. Thisplastic material, also known as thermocole, is an aromatic polymer made from the monomer styrene, a liquid hydrocarbon manufactured from petroleum.With several billion kilograms production scaleper year, this common plastic also allows us to arrange large scale production of thecard holder.

Product Information

| Project Name | Card holder |

| Number of Parts | 2 parts in 1 tooling |

| Material | PS |

| Product Size | 61*50.5*20 |

| Exported Country/Customer | South Africa |

Detailed Business Card holder Mold Information

| Cavity No. | 1*2 | Plastic | PS | Tonnage Of Moulding Machine | 90T |

| Core Cavity Material | 1.2344 Euro Steel | Mold Life Warranty | 500K | Mould Type | 3 plate |

| Mould Size | 300*300*250 | Mold Base | LKM S50C | Mold Features | 2 slider, no lifer |

| Mould Weight | 160 kg | Runner System | Cold runner | Gate Type | Direct gate |

The PS material can either be thermoset or thermoplastic, which areboth available for the business card holder mold. When thethermoplastic polystyrene is adopted, it keeps the solid and glassy state atroom temperature. However, it flows if heated above its glass transition temperature of about100 °C for molding orextrusion, and comes back to the solid state again after cooling.

When using the pure solid polystyrene in the production, the molded businesscard holder comes with no color, certain rigidity and limited flexibility. Inaddition, the PS can also be made to take on various colors, making our moldedproduct variable in color correspondingly. Hence, the mold can meet customer’sdifferent requirements.

Links:https://globefindpro.com/products/64416.html

-

20kW Coal Bed Gas Generator

20kW Coal Bed Gas Generator

-

Stainless Steel Adaptor

Stainless Steel Adaptor

-

Cold Rolled Steel Sheet in Coil

Cold Rolled Steel Sheet in Coil

-

120kW Natural Gas Generator

120kW Natural Gas Generator

-

Hot Rolled Steel Wire Rod

Hot Rolled Steel Wire Rod

-

Semi-Rigid Cable Assembly

Semi-Rigid Cable Assembly

-

Generator Container

Generator Container

-

RF Connector Mold

RF Connector Mold

-

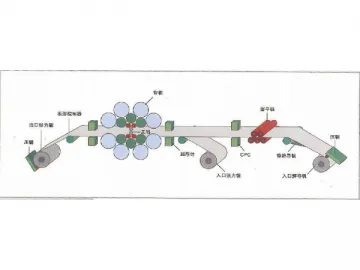

20 Roller Steel Cold Rolling Line

20 Roller Steel Cold Rolling Line

-

Lifter Ring Mold and Parts

Lifter Ring Mold and Parts

-

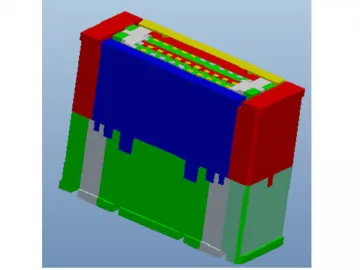

Bluetooth Keypad Mold

Bluetooth Keypad Mold

-

Automotive Connector

Automotive Connector