Welding Manipulator

There are three kinds of welding manipulators which can be controlled by frequency control technology. PLC is also can be used to improve positioning accuracy. The product also can be watched automatically to keep working normally. The beam can move up and down at a constant speed, thus ensuring stability. Heavy duty welding manipulator is equipped with a platform to make operation convenient. A remote controller also makes operation more convenient. And the welding product is suitable for flat welding, butt welding cylindrical products. Vessel fabrication welding equipment is used in combination with the product to weld different kinds of products.

Technical Parameters

| Model | Heavy duty | Moderate duty | Light duty | Precision-type | |||

| 8 x 6 | 5 x 6 | 4 x 5 | 3.5 x 5 | 3 x 4 | 2 x 2 | 3 x 4 | |

| Longitudinal effective stroke (mm) | 8000 | 5000 | 4000 | 3500 | 3000 | 2000 | 3000 |

| Transverse effective stroke (mm) | 6000 | 6000 | 5000 | 5000 | 4000 | 2000 | 4000 |

| Diameter of main body (mm) | 1000-8000 | 1000-5000 | 1000-4000 | 700-500 | 700-3000 | 500-2000 | 700-3000 |

| Rotation angle | ± 180° | ± 180° | ± 180° | ± 180° | ± 180° | (manual) | ± 180° |

| Lifting speed (m/min) | 0.9 | 1 | 1 | 1 | 1 | 0.3 | 1 |

| Telescopic speed (m/min) | 0.12-1.2 | 0.12-1.2 | 0.12-1.2 | 0.12-1.2 | 0.12-1.2 | 0.12-1.2 | 0.12-1.2 |

| Running speed (m/min) | 3 | 3 | 3 | 3 | 3 | 1.5 | 3 |

| Track center distance (mm) | 2308 | 1780 | 1780 | 1780 | 1500 | 900 | 1500 |

Scan QR to Read

Links:https://globefindpro.com/products/70327.html

Links:https://globefindpro.com/products/70327.html

Recommended Products

-

Hydraulic Jack

Hydraulic Jack

-

Strand Jack Lifting System

Strand Jack Lifting System

-

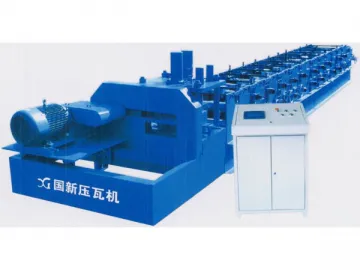

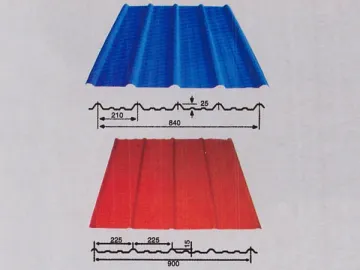

Roll Forming Machine (for Deck Plate)

Roll Forming Machine (for Deck Plate)

-

H-beam Straightening Machine

H-beam Straightening Machine

-

Hydraulic Lifter

Hydraulic Lifter

-

Hydraulic Jacking Equipment

Hydraulic Jacking Equipment

-

Roll Forming Machine (for C/Z/U Purlins)

Roll Forming Machine (for C/Z/U Purlins)

-

Chamfering Machine

Chamfering Machine

-

Self Aligning Pipe Welding Rotator

Self Aligning Pipe Welding Rotator

-

Roll Forming Machine (for Roof Panel and Wall Panel)

Roll Forming Machine (for Roof Panel and Wall Panel)

-

Strand Jack

Strand Jack

-

Conventional Pipe Welding Rotator

Conventional Pipe Welding Rotator