Plastic Bearing (for High Temperature Environment)

Materials

PEEK and PI are two new engineering materials that are becoming more widely used to make plastic bearings. They have been proven to be the best engineering plastic in terms of mechanical strength, dimensional stability and high temperature resistance. The PEEK material can withstand temperatures as high as 260℃ for extended periods of time and the PI can withstand temperatures up to 300℃.

Components

These high temperature resistant bearings have rings made of PEEK or PI, and the cages are made from PTFE, PEEK, or PI. The rollers are made from zirconium oxide (ZrO2) or silicon nitride (Si3N4).

Applications

The plastic bearings also have a high corrosion resistance that enables them to work well, even under moderate acid, alkali, or corrosive conditions. Because of that, the PEEK and PI bearings have become an excellent choice in heat resistant bearings for harsh conditions.

Features

1. High mechanical strength and rigidity

2. High stiffness, even at low temperatures

3. High thermal stability

4. High temperature resistance

5. High dimensional stability

6. High resistance to x-ray and infrared

7. High resistance to hydrolysis (18 atmospheric pressure, 280℃)

Common Materials of Plastic Bearings for High Temperature Environment

| Parts | Common Materials |

| Rings | PEEK |

| Balls | PEEK, ZrO2, SI3N4 |

| Cage | PTFE, PEEK |

Links:https://globefindpro.com/products/70810.html

-

Diaphragm Valve

Diaphragm Valve

-

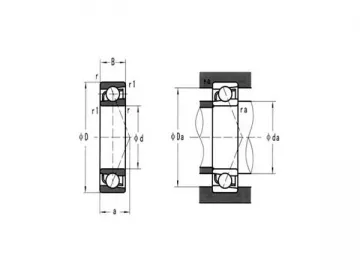

Plastic Angular Contact Ball Bearing

Plastic Angular Contact Ball Bearing

-

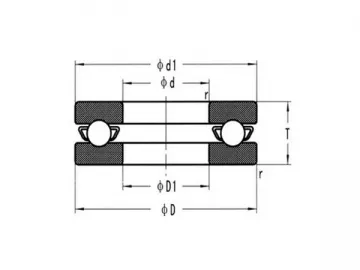

Ceramic Thrust Ball Bearing

Ceramic Thrust Ball Bearing

-

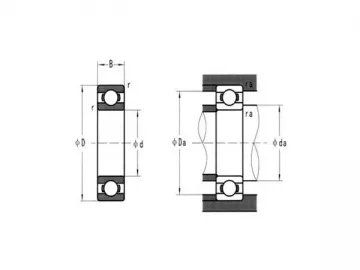

Ceramic Deep Groove Ball Bearing

Ceramic Deep Groove Ball Bearing

-

Ball Valve

Ball Valve

-

Four Point Contact Ball Bearing

Four Point Contact Ball Bearing

-

Transfer Film (Leather Finishing)

Transfer Film (Leather Finishing)

-

Deep Groove Ball Bearing, 619 Series

Deep Groove Ball Bearing, 619 Series

-

Plastic Bearing (for Precision Engineering)

Plastic Bearing (for Precision Engineering)

-

Plug Valve

Plug Valve

-

Deep Groove Ball Bearing, 618 Series

Deep Groove Ball Bearing, 618 Series

-

Gate Valve

Gate Valve